Method and device for ordinary-pressure oxygen-enriched continuous gasification-gas-steam combined cycle power-generation heat supply

A combined power generation and gas-steam technology, which is applied to steam generation methods using heat carriers, mechanical equipment, steam engine devices, etc., can solve problems such as low efficiency, small unit scale, and air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

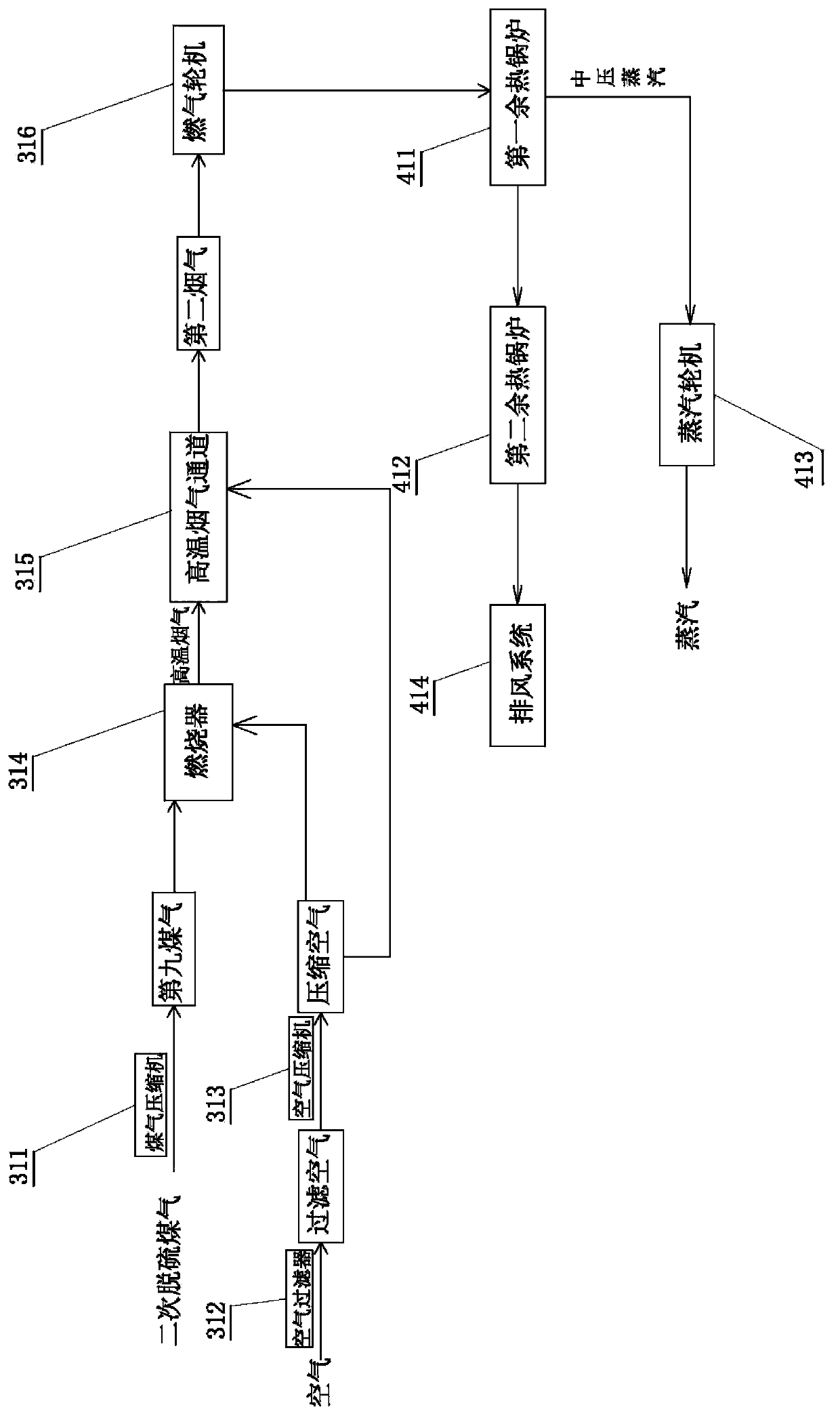

[0071] In order to make the purpose, technical solution and advantages of the atmospheric pressure oxygen-enriched continuous gasification-gas-steam combined power generation and heat supply method and equipment of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0072] The present invention provides a continuous gasification-gas-steam combined power generation and heat supply method at atmospheric pressure. The method comprises the following steps:

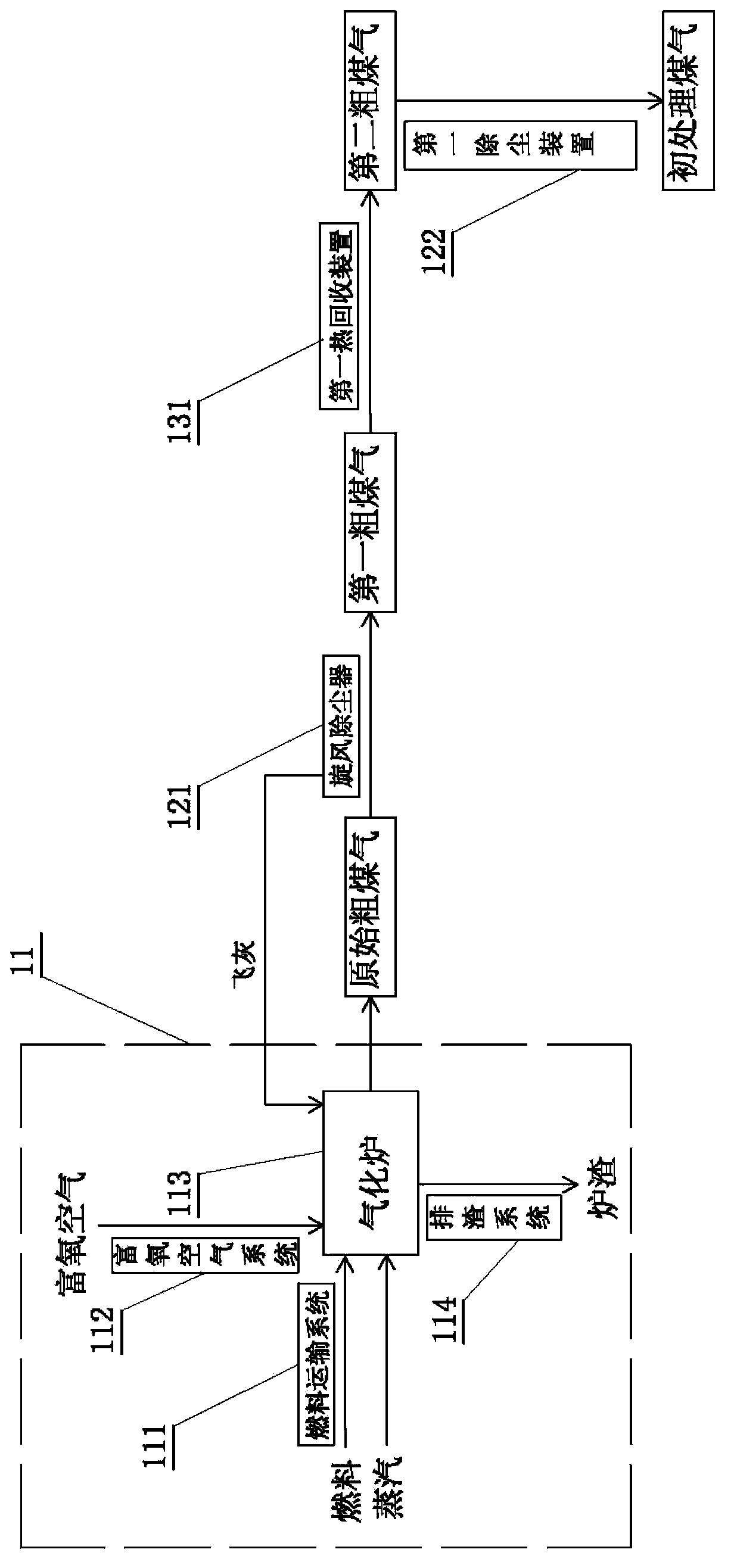

[0073] S100: Produce gas; add fuel, oxygen-enriched air and steam to the gasifier to generate raw crude gas, and then perform dust removal and cooling treatment on the crude gas to obtain primary treated gas; wherein the weight parts of fuel, oxygen-enriched air and steam Ratio is 100:89:54; this step adopts coal gas production part to obtain primary treatment gas;

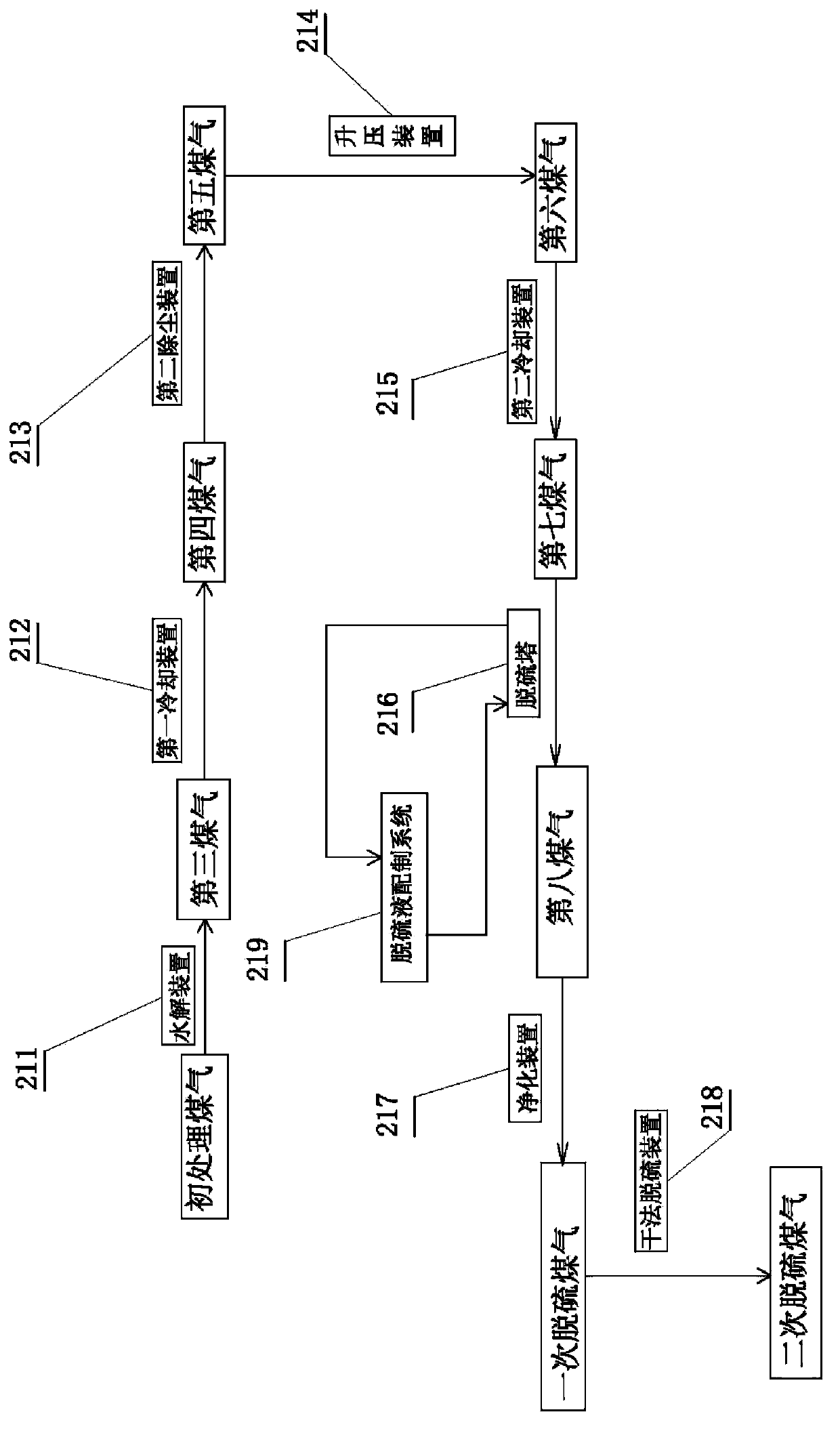

[0074] S200: Coal gas desulfurization: des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com