Fidelity secondary sampling equipment for bottom sediments

A seabed sediment and secondary sampling technology, applied in the sampling device and other directions, can solve the problems of inability to fidelity fidelity effect, low sampling rate of sampling equipment, unable to obtain samples, etc., to achieve good fidelity effect, compact structure, sampling low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

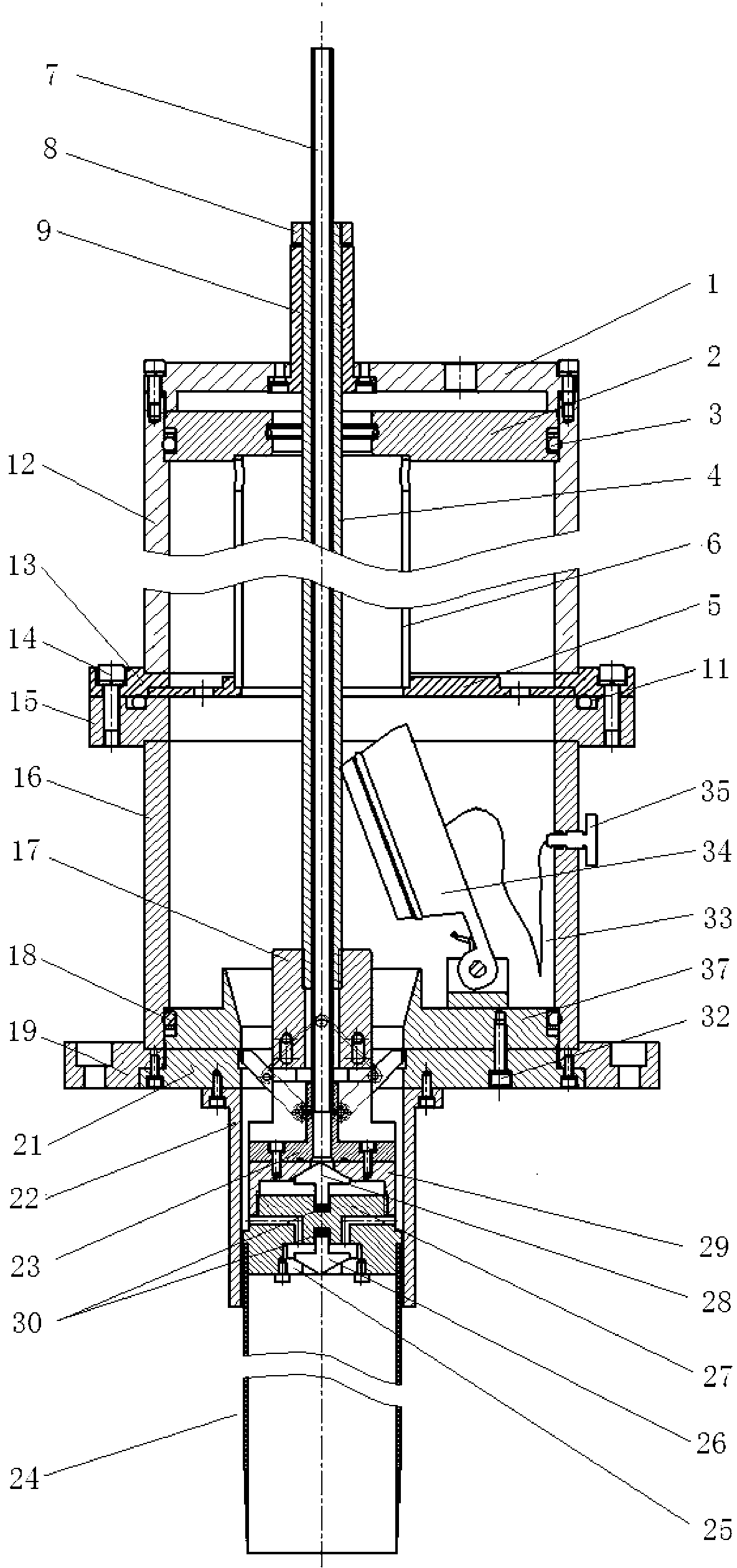

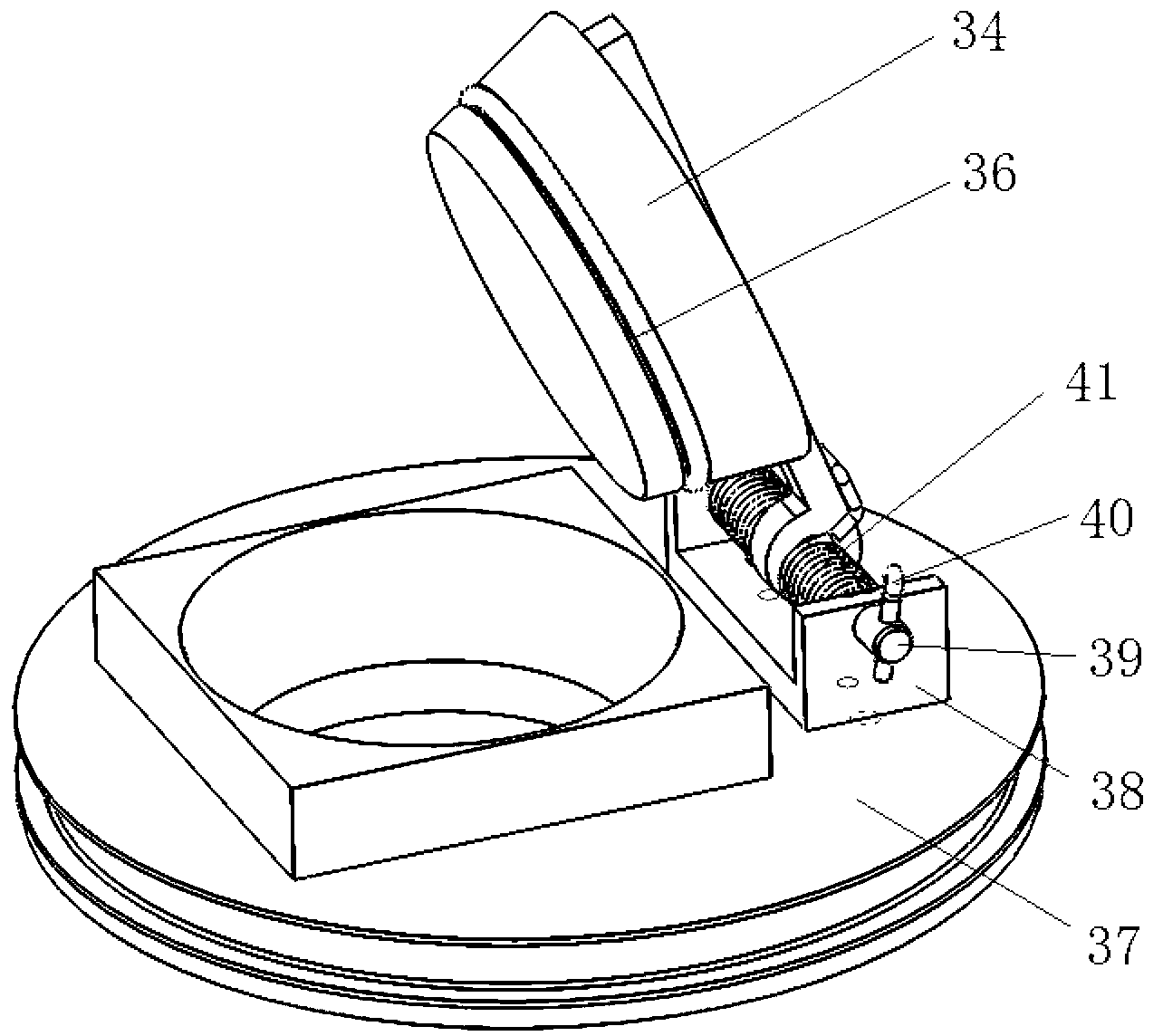

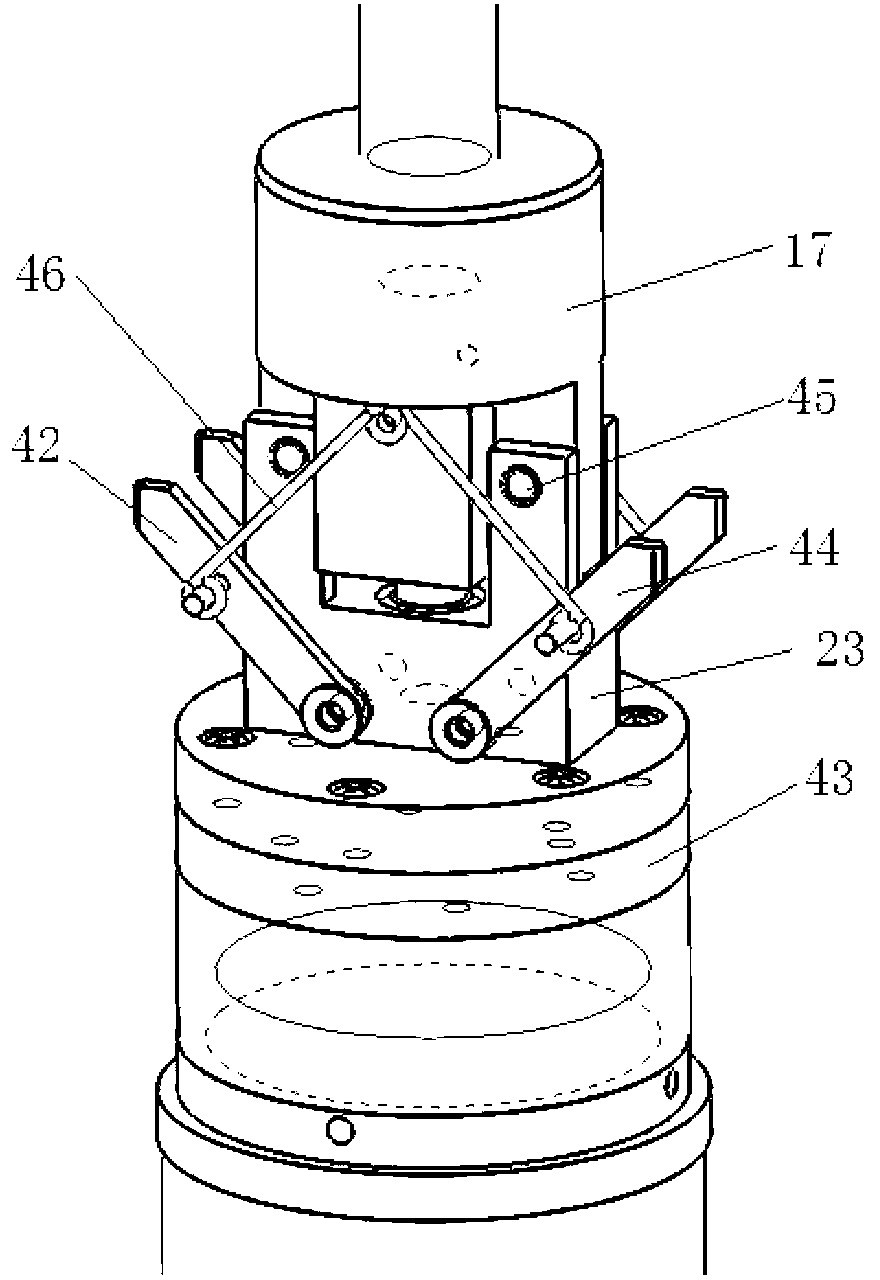

[0037] Embodiment 1: a kind of submarine sediment fidelity secondary sampling equipment of the present invention, its structure is as follows figure 1 As shown, it includes an upper tube assembly, a lower tube assembly, a piston assembly, a flip cover assembly, an intermediate support plate 5, an upper guide rail tube 6, a lower guide rail tube 22, a linear bearing 9 and a lifting hollow tube 4.

[0038] The upper cylinder assembly includes the upper cylinder end cover 1, the upper end sealing plate 2, the upper cylinder body 12, the upper cylinder flange 13, the O-ring and the retaining ring A 3; the upper cylinder body 12 and The upper cylinder end cover 1 is connected by screws; the upper cylinder body 12 and the upper sealing plate 2 are sealed by an O-ring and a retaining ring A3, and the upper cylinder body 12 and the upper cylinder flange 13 are welded and connected; There is an annular groove on the flange section at the lower end of the cylinder flange 13, and an O-ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com