Device for measuring flow rate and flow quantity of gas released by matter at different temperatures

A technology of gas flow rate and mass flow rate, applied in measuring devices, mass flow measuring devices, fluid velocity measurement, etc., it can solve the problems of inability to accurately control the reaction temperature of substances, measurement limitations, human errors, etc., to achieve rich functions, Test the effect of wide temperature range and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

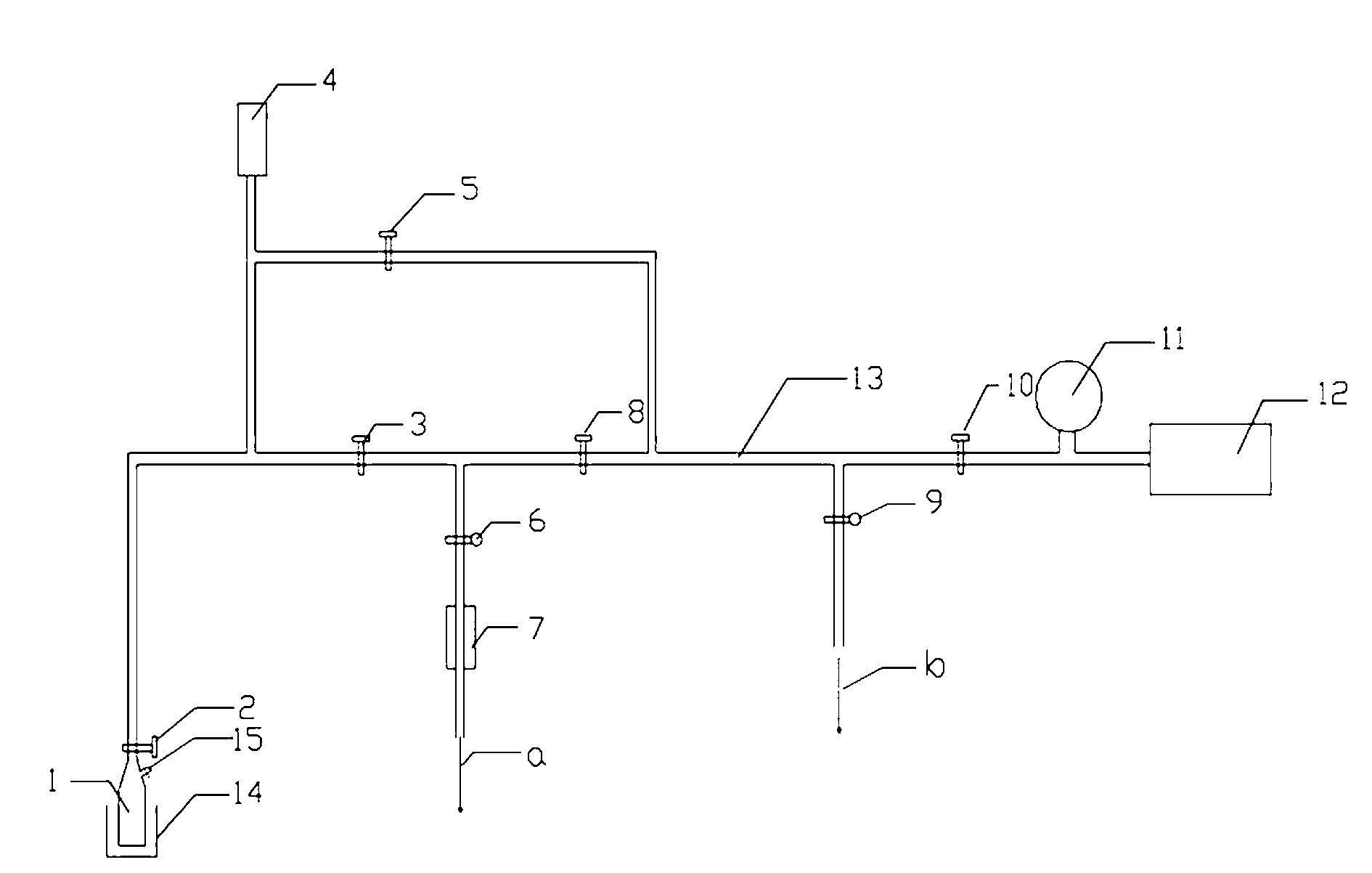

[0029] figure 1 It is a structural schematic diagram of an embodiment of the present invention, including a reaction tank 1, valves 2, 3, 5, 8 and 10, a pressure sensor 4, flow control valves 6 and 9, a mass flow meter 7, a vacuum pressure gauge 11 and a vacuum pump 12 And the pipeline system 13, the temperature control system 14, the feed port 15 with the valve; this embodiment designs a LaNi after hydrogenation under the condition of 80 ℃ that can measure the temperature 5 Powder Release H 2 The device of the rate and amount of release, its physical figure is shown in Figure 4 Shown, wherein the reaction tank 1 is LaNi after hydrogenation 5 Powder, mass flow meter 7 is selected to measure H 2 Dedicated, the maximum pressure 3MPa specification, the pressure sensor 4 selects the maximum range 3MPa specification, and the heating instrument adopts a temperature-controllable heater. First, the hydrogenated LaNi 5 Put the powder into the reaction tank 1, and close the feedin...

Embodiment 2

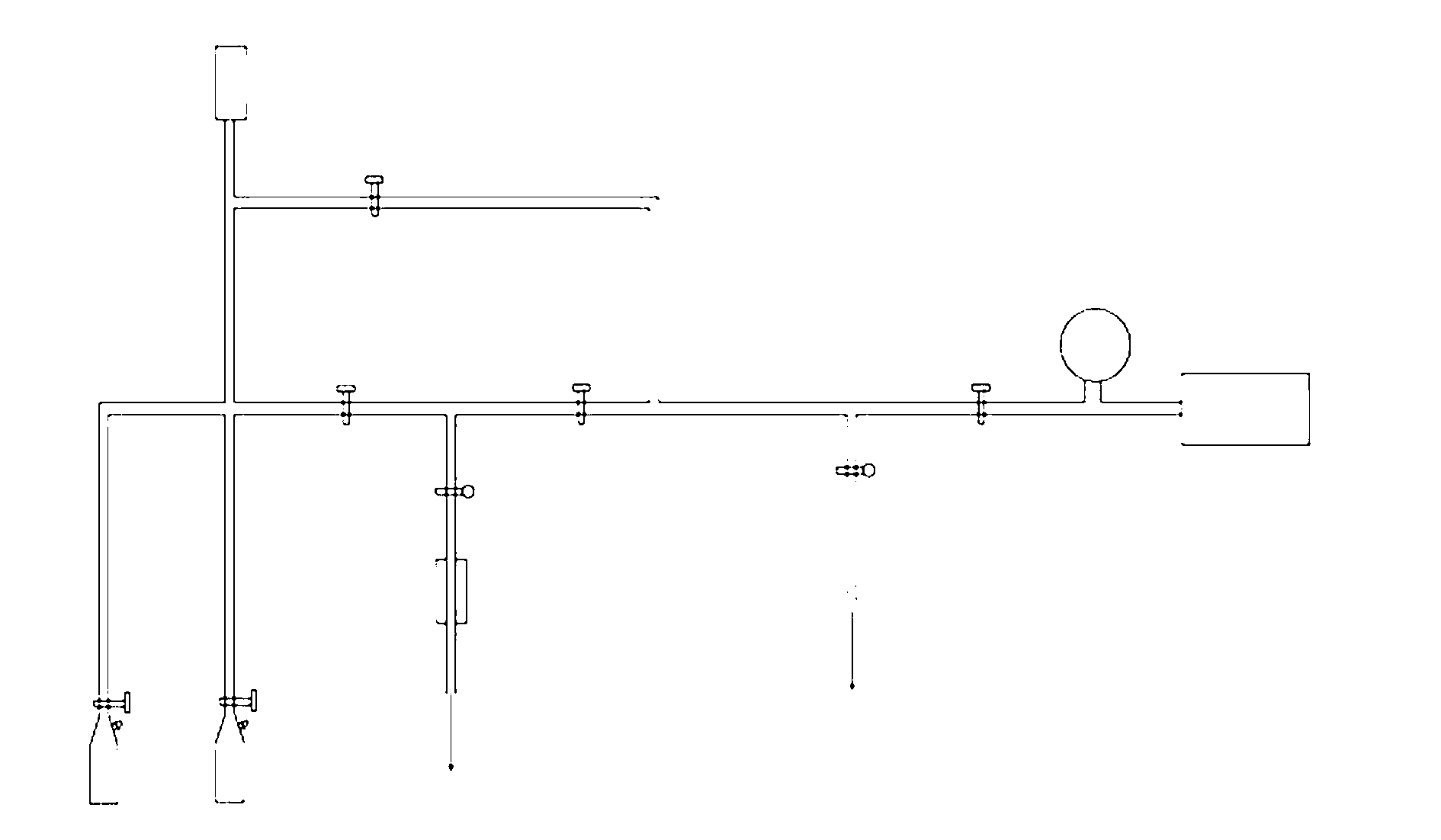

[0031] The overall link of this embodiment is the same as that of Embodiment 1, the difference is that the device adds an additional reaction tank, which can be used as a relatively large amount of gas preparation and collection device, such as image 3 shown.

Embodiment 3

[0033] The overall connection of this embodiment is the same as that of Embodiment 1, except that a refrigeration source is added to a low-temperature heat preservation container to measure the release H of a certain hydrogen storage alloy powder under low temperature conditions. 2 The rate and amount of release, such as Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com