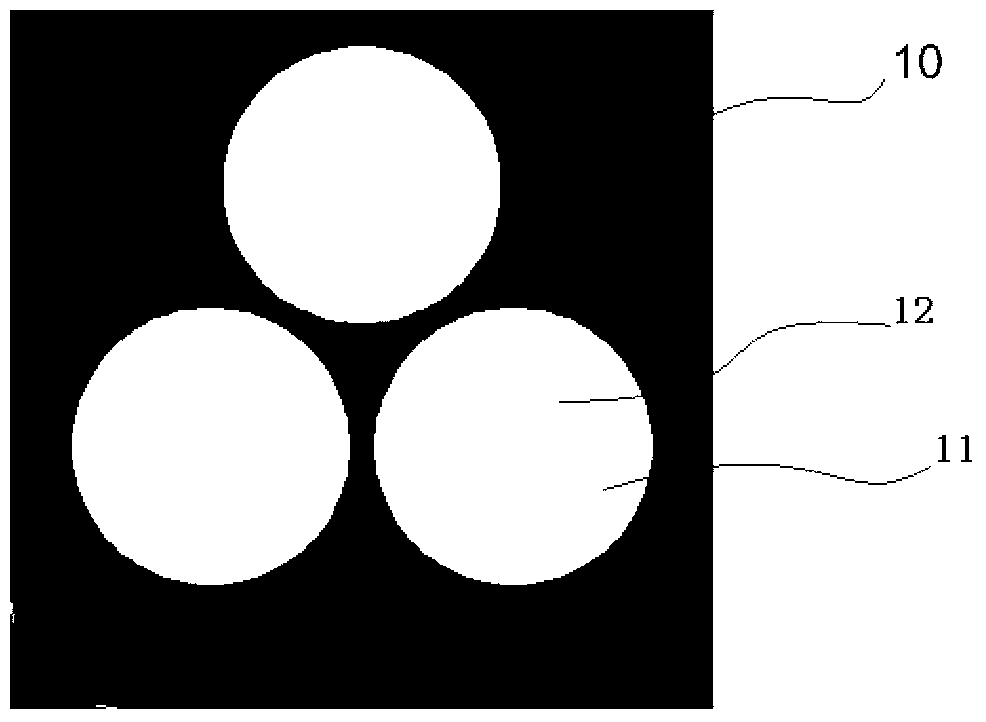

Beam splitting device and multi-beam interference light path system

A multi-beam interference and optical path system technology, applied in the field of micro-nano manufacturing and optical design, can solve the problems of expensive equipment, difficult photonic crystal structure, not compact, etc., and achieve adjustable beam splitting effect, simple overall structure and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

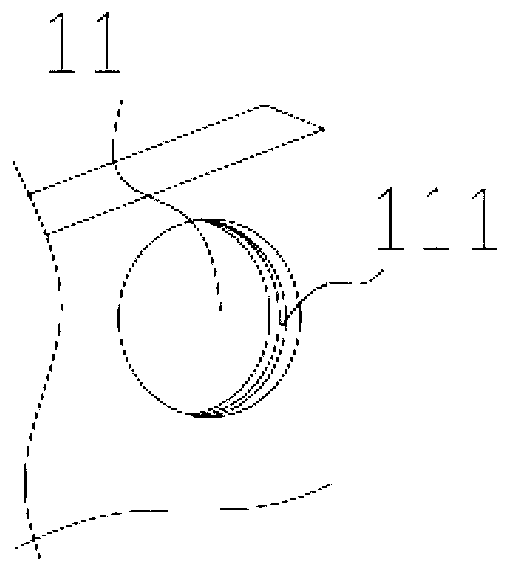

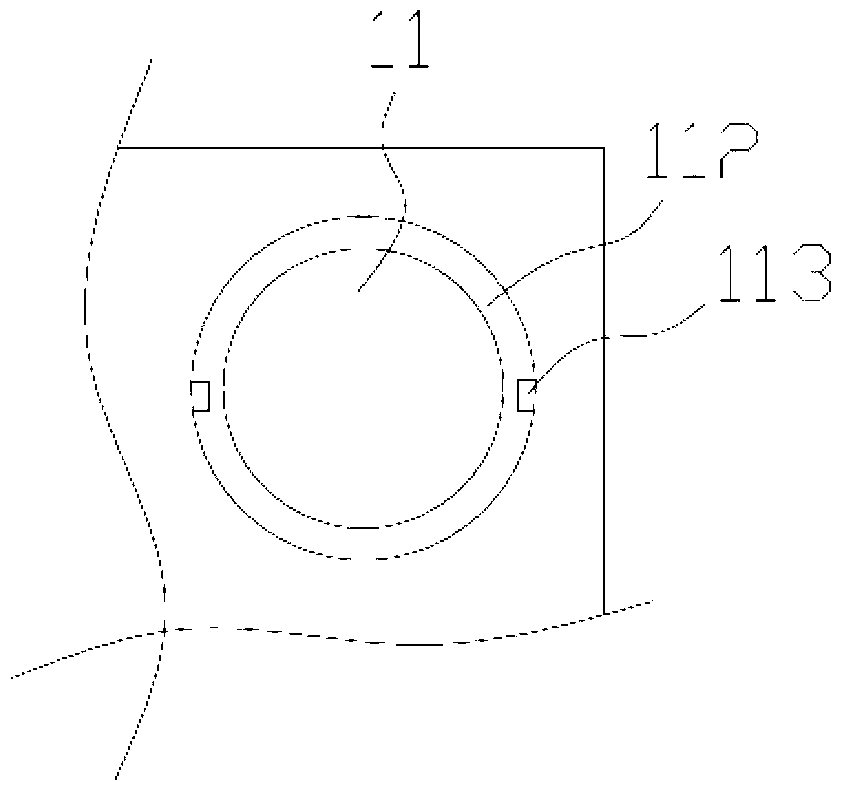

Embodiment Construction

[0024] As mentioned in the background technology, the existing two-dimensional photonic crystal manufacturing method mainly adopts two methods. The first is to perform two or three exposures with double beams, and the second is to perform single exposure with more than three beams of light. exposures. For the first method, in the process of multiple exposures, precise position alignment is required for the two exposures before and after, so as to ensure that the two exposures before and after are carried out in the same area, so that the interference fringes are superimposed to form an interference lattice. Two-dimensional photonic crystal structure. However, this high-precision alignment has strict requirements on the mechanical operation part of the exposure machine. The movement error between each exposure is only allowed at the micron or even sub-micron level. To achieve this alignment requires a high-precision moving workpiece table. Undoubtedly, it brings a cost burden ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com