Membrane gas separation plant and method for operating same

A gas separation and factory technology, which can be used in separation methods, chemical instruments and methods, gas fuels, etc., and can solve problems such as lower yields of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

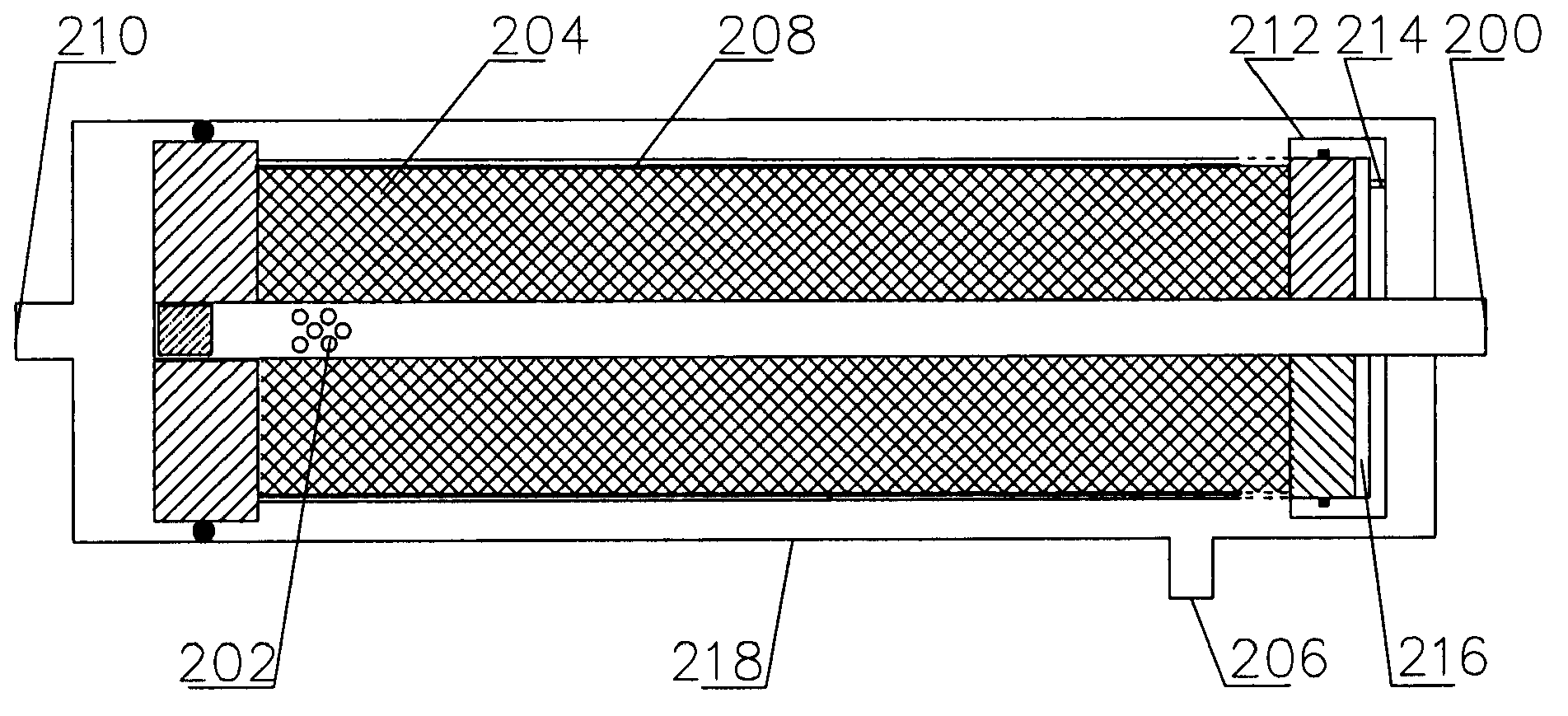

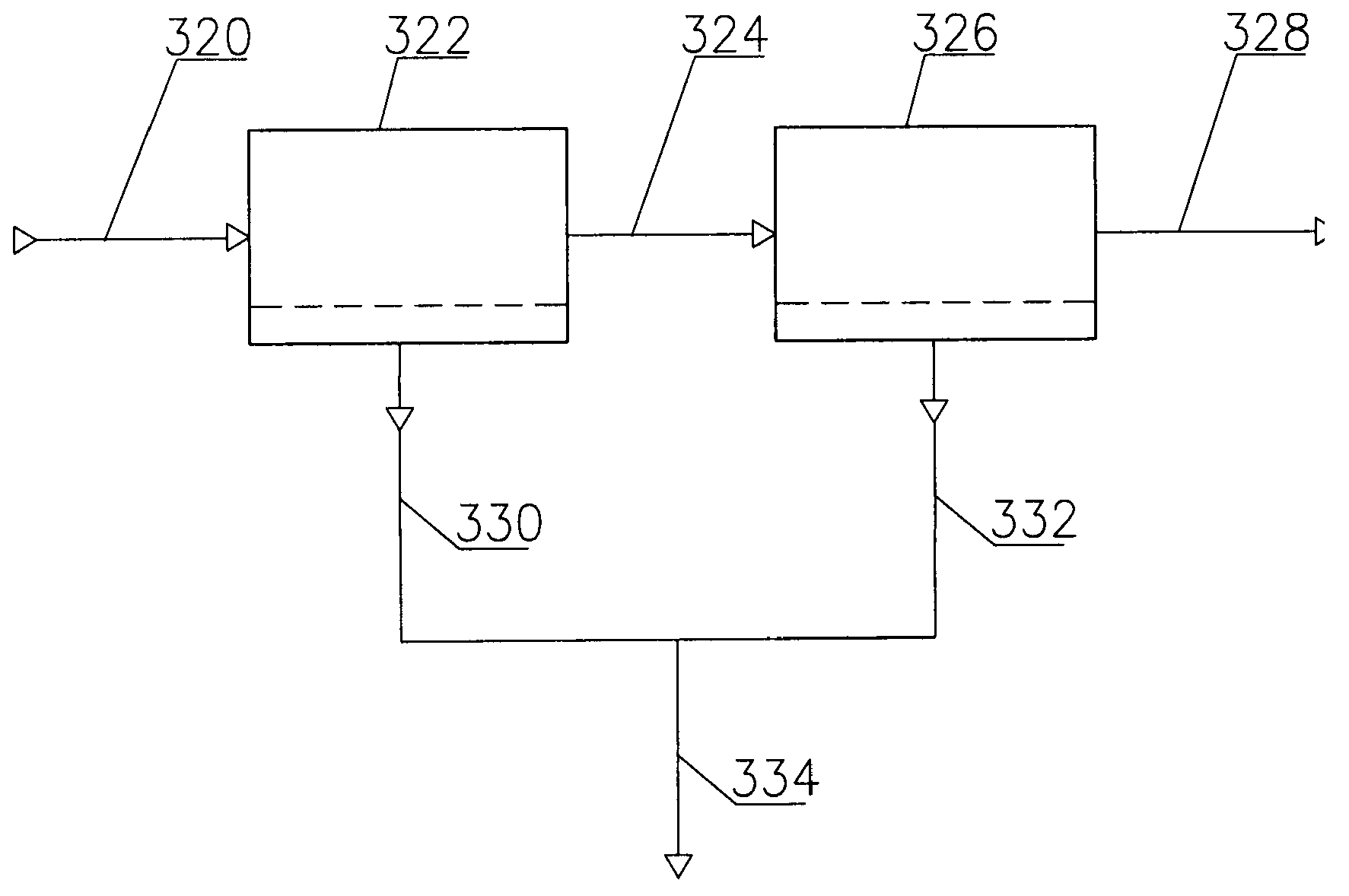

[0105] High Pressure Associated Gas Purification for Water Vapor Removal in a Single Stage Plant

[0106] Feedstock (HPGM with a pressure of 60 bar, water content 0.07% mole, methane 93.6% mole, CO2 2.9% mole, others: hydrocarbons C2–C5) is supplied to the interior of the plant through inlet nozzles, the plant consists of MGSUs connected in parallel with hollow fiber based MGSMs (the structure of the MGSM is in figure 2 shown and described above). Raw material is supplied to MGSM HPC (interfiber space). Part of the gas (permeate) from the HPC permeates through the wall to the LPC (inner fiber channel) when passing along the fiber. The finished product obtained at outlet from HPC (non-permeate) is divided into two parts. The main part is detached through the corresponding nozzles at a pressure of 59 bar. The lesser part (sweeping gas flow) is supplied through a hole in the inner cover to the chamber above the open part of the fiber opposite the outlet, where it is directed...

Embodiment 2

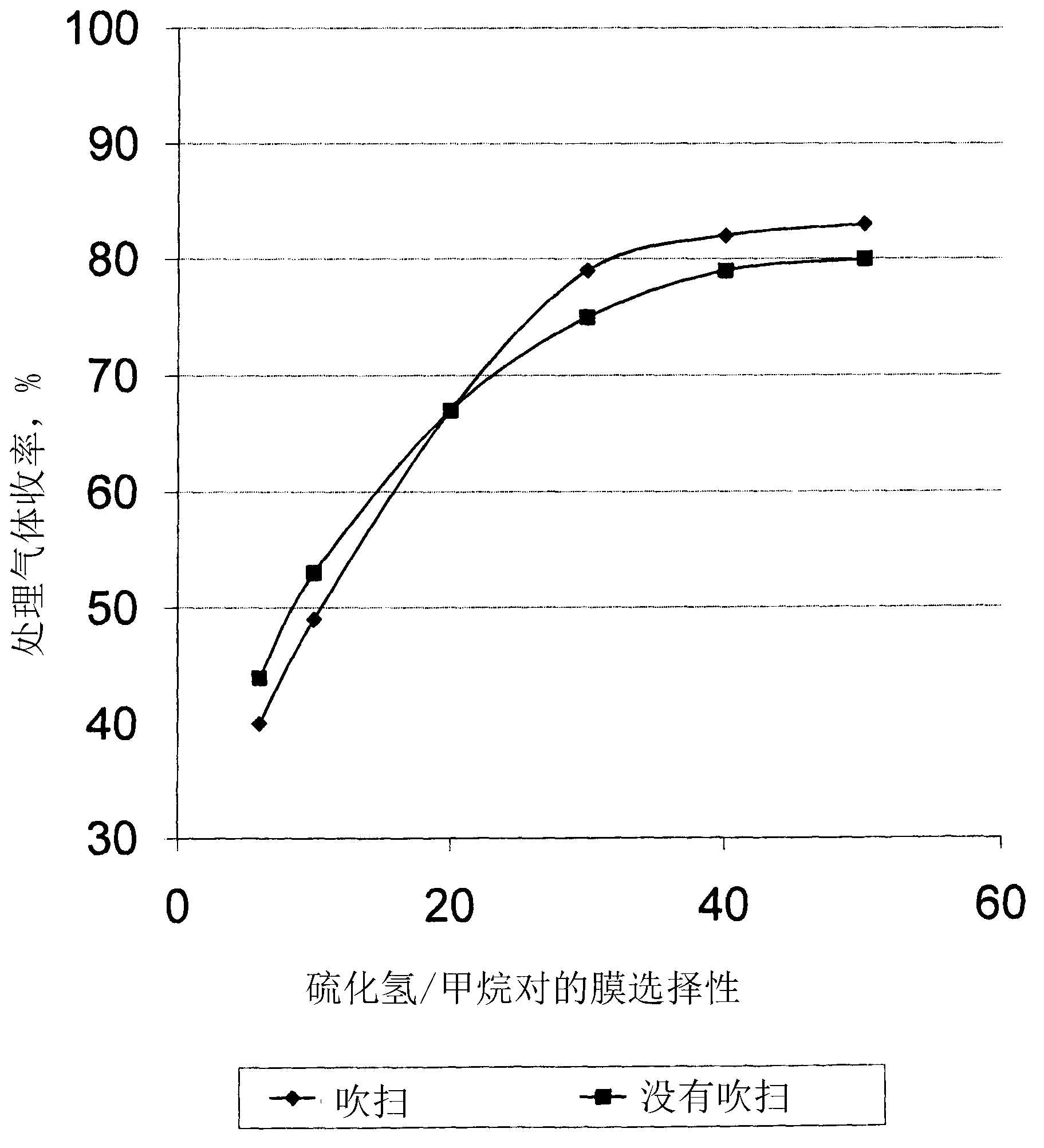

[0109] High-pressure associated gas purification for hydrogen sulfide removal in a single-stage plant

[0110] Raw materials (HPGM with a pressure of 20 bar, hydrogen sulfide content 0.02% mole, methane 88.9% mole, CO2 2.9% mole, nitrogen 0.2% mole, others: hydrocarbons C2–C5) are supplied to the interior of the plant through inlet nozzles, and the plant includes MGSU and MGSMs based on hollow fiber parallel connection (the structure of MGSM is in figure 2 shown and described above). Passing along the fiber, the high-pressure gas mixture components of the gas from the HPC (inner fiber channel) permeate through the wall to the LPC (inner fiber channel), at the same time the mixture strips off easily permeable components, and the resulting finished product (not Permeate) is divided into two parts. The main part of the non-permeate is recovered through the corresponding nozzles at a pressure of 19 bar. A lesser portion of the non-permeate (sweeping gas flow) is supplied throu...

Embodiment 3

[0113] High Pressure Associated Gas Purification for Hexane Removal in a Single Stage Plant

[0114] Feedstock (HPGM with a pressure of 14 bar, hexane content 0.95% mol, methane 70.5% mol, water 0.55% mol) enters the interior of the plant through inlet nozzles, and the plant consists of MGSUs connected in parallel with hollow fiber-based MGSMs (the structure of the MGSM is in figure 2 shown and described above). Feedstock is introduced into the MGSM HPC (interfiber space). When passing along the fiber, components of the gas mixture of the HPC penetrate the fiber walls (inner channels of the fiber) in the LPC. The finished product (non-permeate) was divided into two parts. The main part of the non-permeate is recovered through the corresponding nozzles at a pressure of 14 bar. The lesser portion is supplied through a hole in the inner cover to a chamber above the open portion of the fiber opposite the outlet nozzle, where it is directed to purge the inner fiber channel wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com