Processing method of natural multi-color macaroni

A processing method and macaroni technology, which is applied in the field of macaroni processing, can solve the problems of lack of durum wheat resources and the inability to make macaroni, and achieve the effect of increasing protein content and balanced and healthy diet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

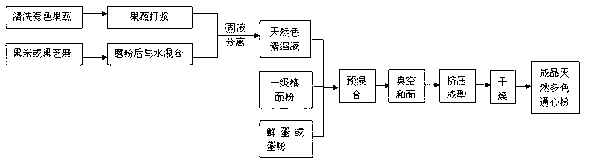

Image

Examples

Embodiment 1

[0012] The production of natural green macaroni: clean and chop 10 kg of spinach, then put the crushed spinach into a beater, add 4 liters of water, beat the spinach into a slurry, use a 200-mesh filter centrifuge, and pass solid-liquid Separate and obtain 10 kilograms of natural pigment solution, then dilute the natural pigment solution into 50 kilograms for later use; get 180 kilograms of first-grade refined flour with a gluten degree of 27%, 38 kilograms of fresh eggs or 6 kilograms of egg powder. Mix the flour, dilute solution and fresh eggs or egg powder in a primary mixer (double shaft) for 5 minutes to form a primary dough, and then enter the secondary vacuum mixer (single shaft) to mix for about 10 minutes to form a dough. The mixed dough is sent into the macaroni extruder by a vertical screw conveyor, and the extrusion stress is 4.5 MPa. The cylinder wall of the extruder is double-layered, and the cavity is cooled by water. A forming die is installed at the outlet end...

Embodiment 2

[0014] The production of natural green macaroni: clean and chop 10 kg of spinach, then put the chopped spinach into a beater, add 4 liters of water, beat the spinach into a slurry, and use a 200-mesh filter centrifuge to separate the solid-liquid Separate to obtain 10 kg of natural pigment solution, then dilute the natural pigment solution into 50 kg for subsequent use; get 180 kg of first-grade refined flour with a gluten degree of 30%, 27 kg of fresh eggs or 4.5 kg of egg powder. Mix the flour, diluted solution and fresh eggs or egg powder in a primary mixer (double shaft) for 10 minutes to form a primary dough, and then enter the secondary vacuum mixer (single shaft) to mix for about 7 minutes to form a dough. The mixed dough is sent into the macaroni extruder by the vertical screw conveyor. The cylinder wall of the extruder is double-layered, and the cavity is cooled by water. A forming die is installed at the outlet end of the cylinder liner, and the wet flour is extruded...

Embodiment 3

[0016] The production of natural green macaroni: clean and chop 10 kg of spinach, then put the chopped spinach into a beater, add 4 liters of water, beat the spinach into a slurry, and separate the solid and liquid with a 200-mesh filter centrifuge , Obtain 10 kg of natural pigment solution, then dilute the natural pigment solution into 50 kg for subsequent use; get 180 kg of 28% first-grade fine flour, 33 kg of fresh eggs or 5 kg of egg powder. Mix the flour, diluted solution and fresh eggs or egg powder in the primary mixer (double shaft) for 8 minutes to form a primary dough, and then enter the secondary vacuum mixer (single shaft) to mix for about 8 minutes to form a dough. The mixed dough is sent into the macaroni extruder by the vertical screw conveyor. The cylinder wall of the extruder is double-layered, and the cavity is cooled by water. A forming die is installed at the outlet end of the cylinder liner, and the wet flour is extruded from the die hole and cut into wet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com