Waterless reverse micelles nanoparticles of water-soluble drug, and preparation method of suspension aerosol thereof

A technology for suspension-type aerosols and water-soluble drugs, applied in the field of biomedicine, can solve the problems of consuming a large amount of energy, destroying and degrading the molecular structure of drugs, and reducing the effect of reducing drug loss, facilitating storage and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Preparation of blank lipid vesicles

[0039] The preparation method of blank lipid vesicles comprises the following steps:

[0040] Use ultrapure water as the water phase, and dissolve the amphiphilic substance soybean lecithin in tert-butanol, and the resulting solution with a concentration of 5% (w / v) is used as the oil phase. Add dropwise into ultrapure water, the volume ratio of the water phase to the oil phase is 8:1, pass through a 220nm organic filter membrane to segregate and remove bacteria at the same time to obtain a blank lipid vesicle suspension. From the above, it can be seen that by using this method, a lipid vesicle structure with a uniform particle size can be prepared in one step.

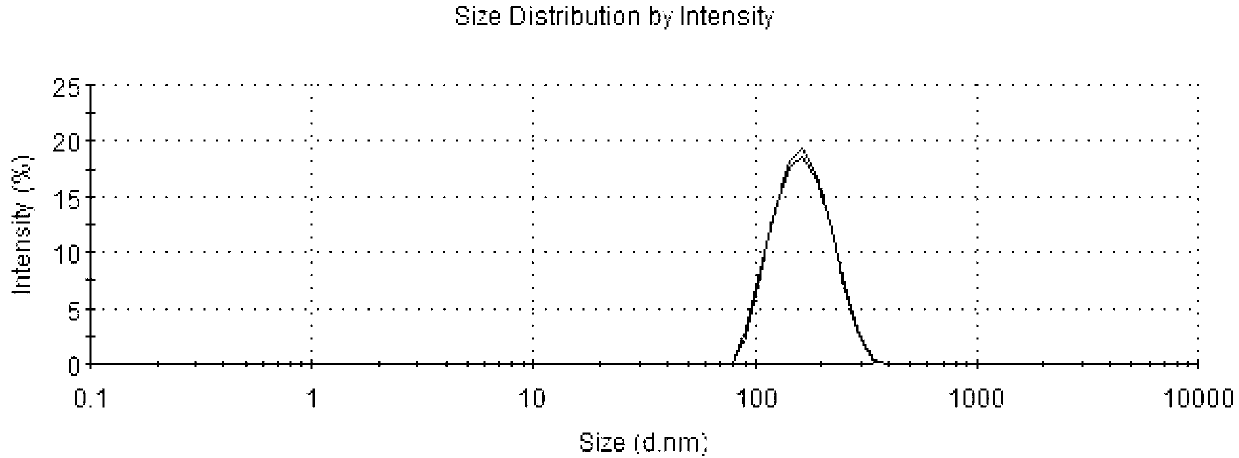

[0041] Adopt the Malvem Zetasizer Nano ZS90 of British Malvern Company to measure the particle size and distribution of the obtained blank lipid vesicles by dynamic light scattering method, the results are as follows Figure 1-A : As can be seen from this figure,...

Embodiment 2

[0042] Example 2 Preparation of salbutamol sulfate lipid vesicles

[0043] The preparation method of salbutamol sulfate lipid vesicle, comprises the steps:

[0044] Dissolve 8 mg of the water-soluble drug salbutamol sulfate in ultrapure water as the water phase, and dissolve the amphiphilic substance egg yolk phospholipid in tert-butanol, and the resulting solution with a concentration of 20% (w / v) is used as the oil phase, and put it in a water bath at 40°C , under the condition of magnetic stirring 1000rpm, add the oil phase into the water phase drop by drop, the volume ratio of the water phase and the oil phase is 4:1, pass through a 220nm organic filter membrane to granulate and remove bacteria at the same time, to obtain salbutamol sulfate lipid vesicle suspension liquid.

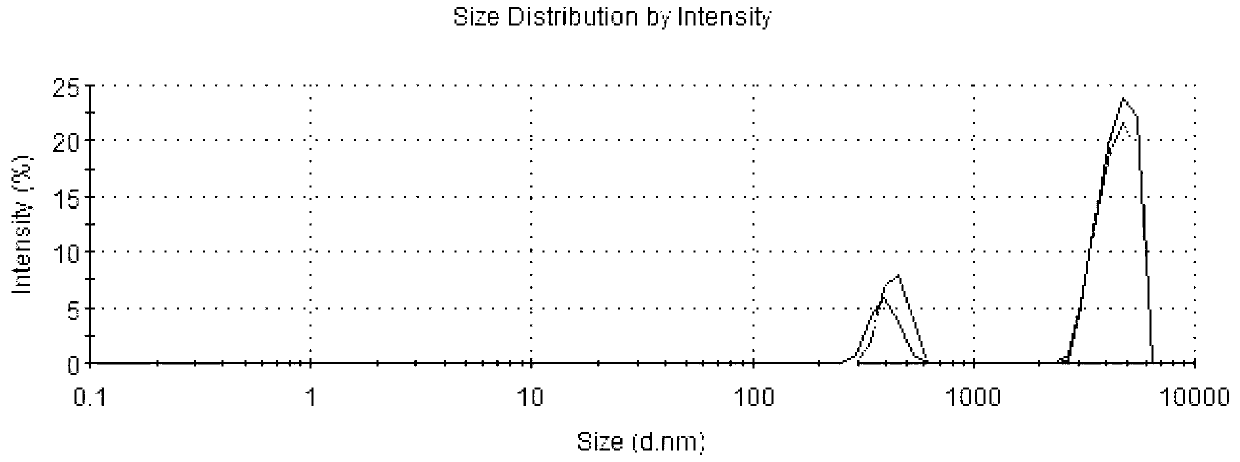

[0045] Adopt the Malvem Zetasizer Nano ZS90 of British Malvern Company to carry out the measurement of particle size and distribution to the obtained salbutamol sulfate lipid vesicles by dynamic light...

Embodiment 3

[0046] Example 3 Preparation of lysozyme lipid vesicles

[0047] A method for preparing lysozyme lipid vesicles, comprising the steps of:

[0048](1) Dissolve 4 mg of water-soluble drug lysozyme and 2 mg of lyoprotectant lactose in ultrapure water as the water phase, and dissolve the amphiphilic substance phosphatidylcholine in tert-butanol to obtain a concentration of 10% (w / The solution of v) is used as the oil phase. Under the condition of a water bath at 35°C and magnetic stirring at 1200rpm, the oil phase is dropped into the water phase. The volume ratio of the water phase to the oil phase is 5:1. The lysozyme lipid vesicle suspension was obtained.

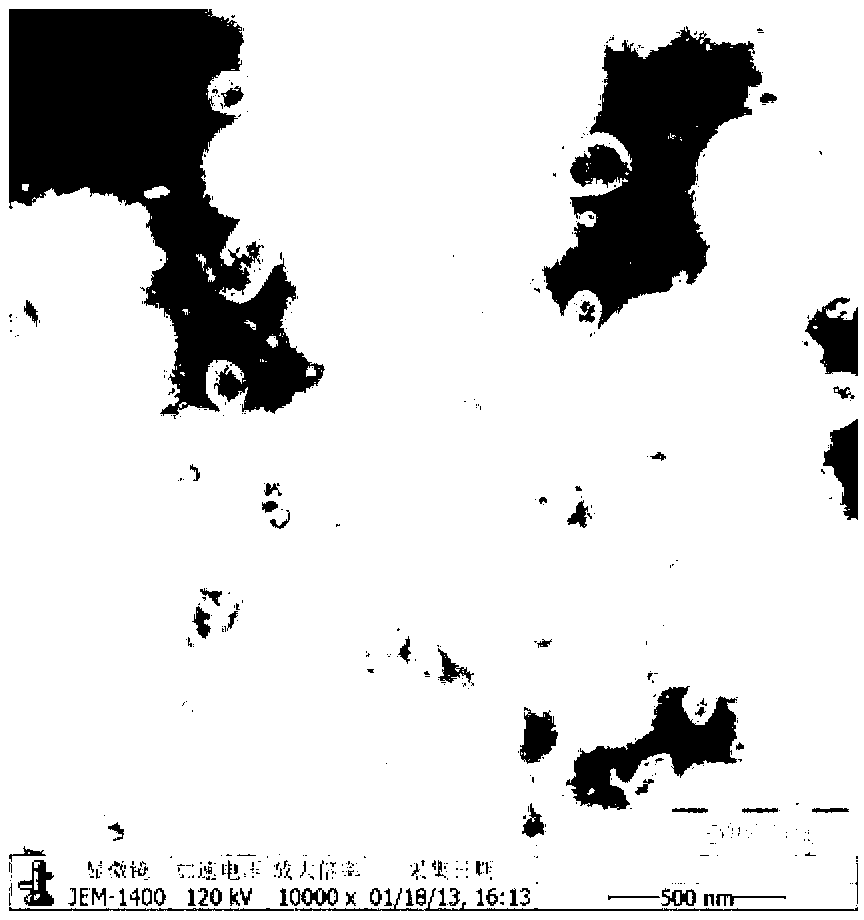

[0049] The particle size and distribution of the obtained lysozyme lipid vesicles were measured using a Malvem Zetasizer Nano ZS90 from Malvern, UK, using the dynamic light scattering method. The average particle size was 166.0±9.0 nm, and the polydispersity coefficient PI was 0.14±0.06. Comparing Example 1 and Example 3, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com