Method for cleaning continuous electric demineralizer

A technology of electrostatic desalination and cleaning box, applied in separation methods, chemical instruments and methods, semi-permeable membrane separation, etc., can solve problems such as hardened organic and biological pollutants, achieve good effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

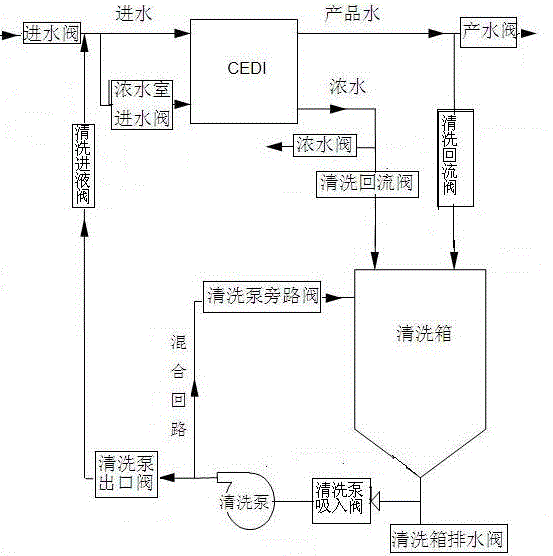

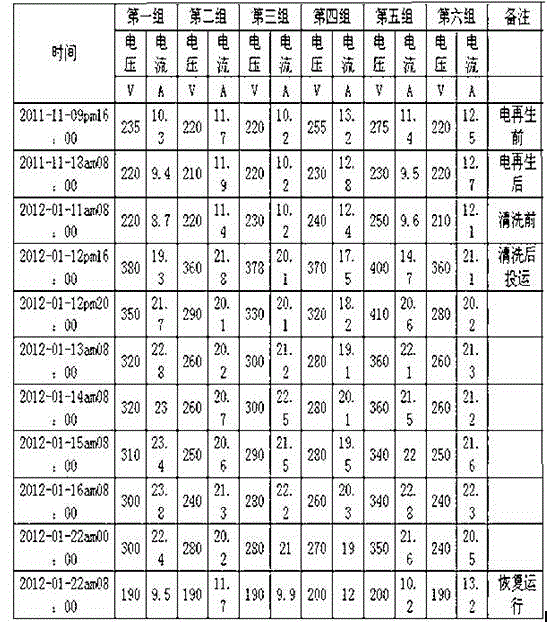

[0037] From January 11th to January 22nd, 2012, NaCl / NaOH cycle cleaning was carried out for the 2#CEDI system of the boiler feed water treatment system for the Taiyuan Iron and Steel 2×300MW unit. 2#CEDI has been in operation for three years, the operating voltage has been increased from the initial 120V to 270V, and the electrical reduction effect is not very obvious. According to the actual configuration of the cleaning system on site, formulate the following plan:

[0038] 1. Configure 4000L of cleaning liquid chemicals and other cleaning materials:

[0039] .

[0040] 2. Cleaning method:

[0041] Flush the pipeline until it is clean, and replace the filter element with a new security filter. Do not power the membrane stack during the cleaning process.

[0042] a. Cleaning flow

[0043] .

[0044] b. Cleaning steps:

[0045] 1. Prepare 5% (mass percentage) NaCl solution (200Kg), flush the CEDI membrane stack, and discharge while flushing. The flow rate of produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com