A kind of deep defluorination agent and preparation method thereof

A chemical and in-depth technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc. Problems such as high fluoride content, to achieve good dehydration performance, dense mass precipitation, fast precipitation, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

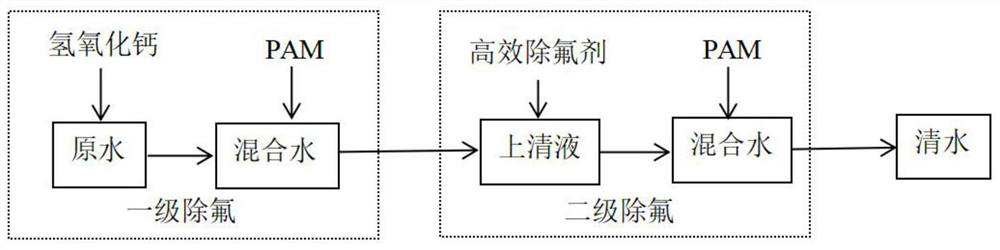

Method used

Image

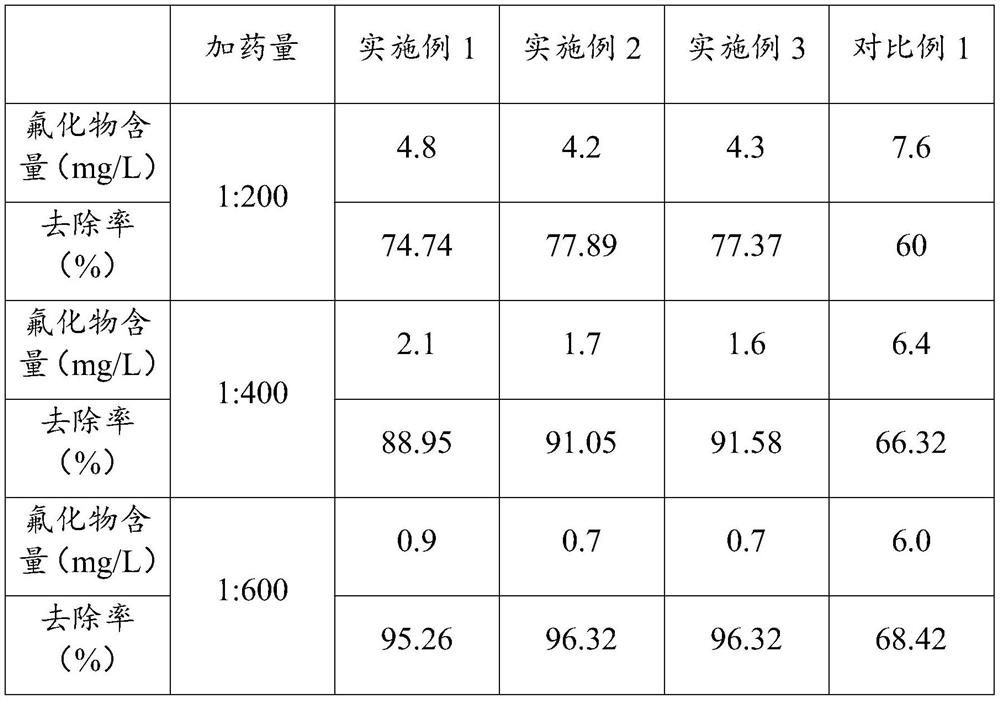

Examples

preparation example Construction

[0037] Iron salt is nano iron silicate, and its preparation method comprises the following steps:

[0038] At room temperature, after mixing ferrous sulfate monohydrate and sodium silicate evenly, add a mixed solution of nitric acid with a mass concentration of 98% and sulfuric acid with a mass concentration of 93% and stir to react, allowing the raw materials to react at 0-90°C After 24-48 hours, after the reaction is complete, the product is taken out and pulverized, and the product is left for 24-48 hours to obtain nanometer iron silicate.

[0039] In order to further optimize the above technical scheme, the acid includes one or more of hydrochloric acid, sulfuric acid and phosphoric acid.

[0040] Further, the calcium salt includes one or more of calcium chloride, calcium citrate and calcium acetate.

[0041] Further, aluminum salts include polyaluminum chloride.

[0042] Further, the magnesium salt includes one or more of magnesium chloride, magnesium sulfate, magnesium...

Embodiment 1

[0053] A novel defluoridation agent, the preparation method comprising the following steps:

[0054] S1: Preparation of nano iron silicate: at room temperature, mix and stir the solid raw material ferrous sulfate monohydrate and sodium silicate in a molar ratio of 1:0.017, then add nitric acid with a mass concentration of 98% and a mass concentration of 93% A mixed solution of sulfuric acid, wherein the molar ratio of ferrous sulfate monohydrate: nitric acid: sulfuric acid is 1:0.330:1.349, the raw materials are stirred and reacted, and the heat released during the reaction will cause the reaction temperature to rise continuously and accompanied by the formation of NO , to accelerate the reaction, the reaction time is 24 hours, and the reaction temperature is controlled at 0-90°C to complete the oxidation and polymerization reactions between the raw materials. After the reaction is complete, the reactants are taken out and crushed, and placed for 24-48 hours to obtain nano Iro...

Embodiment 2

[0060] A novel defluoridation agent, the preparation method comprising the following steps:

[0061] S1: Preparation of nano-ferric silicate: at room temperature, mix and stir the solid raw material ferrous sulfate monohydrate and sodium silicate in a molar ratio of 1:0.062, then add nitric acid with a mass concentration of 98% and a mass concentration of 93% A mixed solution of sulfuric acid, wherein the molar ratio of ferrous sulfate monohydrate: nitric acid: sulfuric acid is 1:0.371:1.413, the raw materials are stirred and reacted, and the heat released during the reaction will cause the reaction temperature to rise continuously and accompanied by the formation of NO , to accelerate the reaction, the reaction time is 35 hours, and the reaction temperature is 0-90°C, so as to complete the oxidation and polymerization reactions between the raw materials. After the reaction is complete, the reactants are taken out and crushed, and placed for 24-48 hours to obtain nano-silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com