an alternative to cabr 2 Strong inhibition and low corrosion brine completion fluid and preparation method thereof

A low-corrosion, well-completion fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of slow dissolution rate, loss of oil-producing capacity, reduction of oil-reservoir productivity, etc. The effect of low self performance and reservoir damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

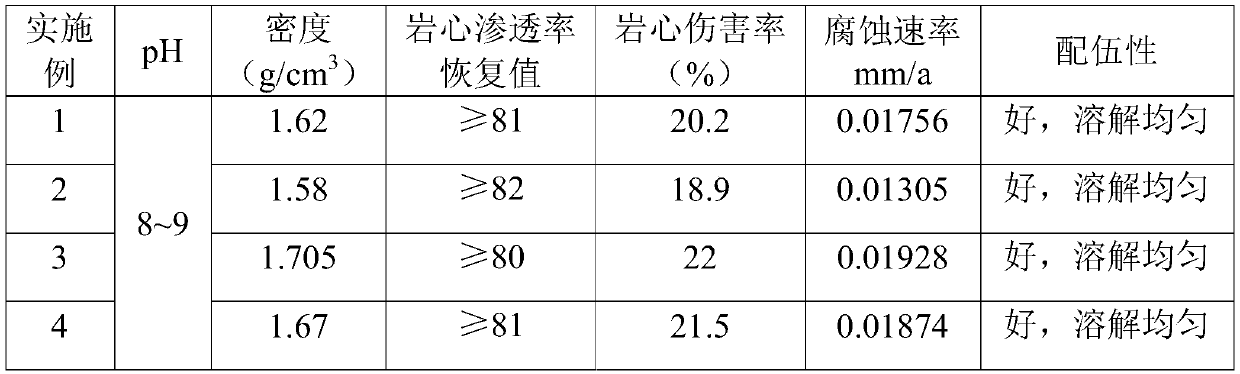

Examples

Embodiment 1

[0022] Add 32 parts of deionized water, 60 parts of complex potassium salt (the mass ratio of potassium formate and potassium pyrophosphate is 1.5:8.5), 2 parts of clay antiswelling agent, and 1.5 parts of acrylic acid-acrylamide copolymer fluid loss control agent Stir in the reaction flask evenly, and stir at room temperature for 0.5-1h; then add 1 part of hydrophobically modified sodium alginate to the reaction flask, and continue stirring for 0.5-1h to make the mixed system uniform; finally add 3.5 parts of organic amine corrosion inhibitor, Baracor300, continue to stir until a uniform transparent strong-inhibited low-corrosion brine completion fluid is formed.

Embodiment 2

[0025] Add 37 parts of deionized water, 55 parts of compound potassium salt (the mass ratio of potassium formate and potassium pyrophosphate is 2:8), 1.5 parts of clay anti-swelling agent, and 2 parts of sulfonated starch into the reaction flask and stir evenly, and Stir at room temperature for 0.5 to 1 hour; then add 1.5 parts of hydrophobically modified sodium alginate to the reaction flask, and continue to stir for 0.5 to 1 hour to make the mixed system uniform; finally add 3 parts of imidazoline corrosion inhibitor to the reaction flask , continue to stir until a uniform transparent strong inhibition low corrosion brine completion fluid is formed.

Embodiment 3

[0027] Add 11.5 parts of deionized water, 80 parts of compound potassium salt (the mass ratio of potassium formate and potassium pyrophosphate is 1:9), 1 part of clay anti-swelling agent, and 1.5 parts of carboxymethyl cellulose into the reaction bottle and stir evenly , and stirred at room temperature for 0.5 to 1 hour; then added 2 parts of hydrophobically modified sodium alginate to the reaction bottle, and continued to stir for 0.5 to 1 hour to make the mixed system uniform; finally, added 4 parts of cyano-inorganic compound to the reaction bottle The corrosion inhibitor, Baracor 450, was stirred until a uniform clear, strongly inhibited, low-corrosion brine completion fluid was formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com