Manufacturing method and system of transparent patterning carbon nano tube conducting thin film

A technology of transparent conductive film and carbon nanotubes, which is applied to the device and coating of the surface coating liquid, can solve the problems that the etching process cannot meet the use requirements, the production efficiency is low, and the size is limited, and the process parameters are easy to reach. The effect of control, low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

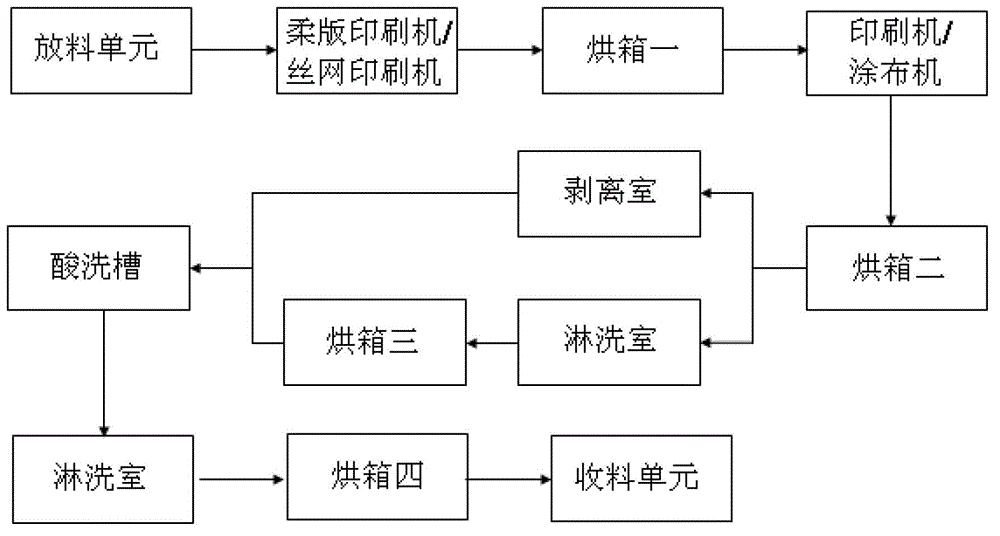

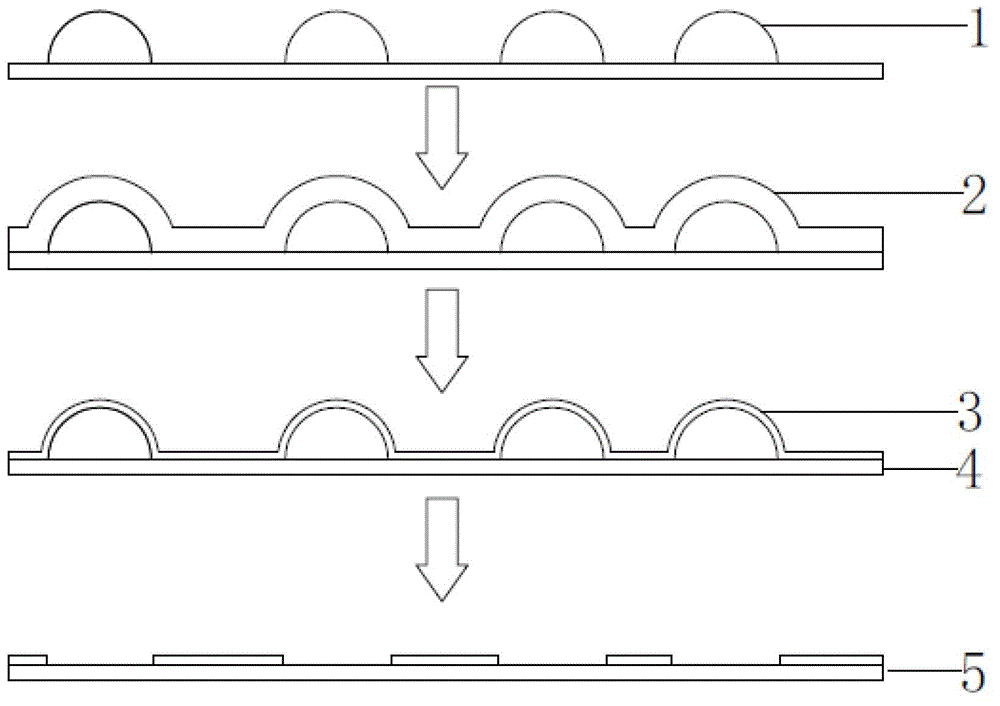

[0083] Dissolve polyvinyl alcohol (AH-26) in water to obtain a viscous aqueous solution of polyvinyl alcohol (AH-26), pour the solution into the ink tank of the flexographic printing machine; disperse the configured carbon nanotubes Liquid (concentration is 0.5wt%) joins in the ink tank of gravure printing machine; Start the machine button, adjust the mechanical speed to be 5m / min, adjust the unwinding tension to be 5kg, the winding tension to be 5.5kg, adjust oven one, oven two 1. The drying temperature of oven 3 and oven 4 is 100°C; when the temperature of the oven rises to the set temperature, press the start button, and the PET (polyethylene terephthalate) film will move around under the traction of the guide film. Can refer to figure 1 Firstly, the polyvinyl alcohol (AH-26) aqueous solution is printed on the PET film through a flexographic printing machine, and then it is introduced into the oven one and dried under hot air at 100°C to form a polyvinyl alcohol coating lay...

Embodiment 2

[0085] Polyvinylpyrrolidone (PVP) is dissolved in water to obtain a viscous aqueous solution of polyvinylpyrrolidone (PVP), which is poured into the ink tank of a flexographic printing machine; the configured carbon nanotube dispersion (with a concentration of 0.5wt%) joins in the ink tank of dimple coater; Start the machine button, adjust the mechanical speed to be 5m / min, adjust the unwinding tension to be 5kg, and the winding tension to be 5.5kg, adjust oven one, oven two, oven The drying temperature of Sanhe Oven 4 is 100°C; when the temperature of the oven rises to the set temperature, press the start button, and under the traction of the guide film, the PET (polyethylene terephthalate) film walking process can be referred to figure 1 Firstly, the polyvinylpyrrolidone (PVP) aqueous solution is printed on the PET film through a flexographic printing machine, and then it is introduced into the oven 1 and dried under hot air at 100°C to form a PVP coating with a set pattern s...

Embodiment 3

[0087]Epoxy resin is dissolved in ethyl acetate, obtains the ethyl acetate solution of viscous epoxy resin, this solution is poured in the ink tank of flexographic printing machine; 0.5wt%) into the ink tank of the gravure printing machine; start the machine button, adjust the mechanical speed to 5m / min, adjust the unwinding tension to 5kg, and the winding tension to 5.5kg, adjust the drying of oven one and oven three The temperature is 80°C, and the drying temperature of oven 2 and oven 4 is adjusted to 100°C; when the temperature of the oven rises to the set temperature, press the start button, and under the traction of the guide film, PET (polyethylene terephthalate) Ester) film walking process can refer to figure 1 First, print the ethyl acetate solution of epoxy resin on the PET film through a flexographic printing machine, then import it into an oven 1, and dry it under hot air at 80°C to form an epoxy resin coating with a predetermined structural pattern; The dried PET...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com