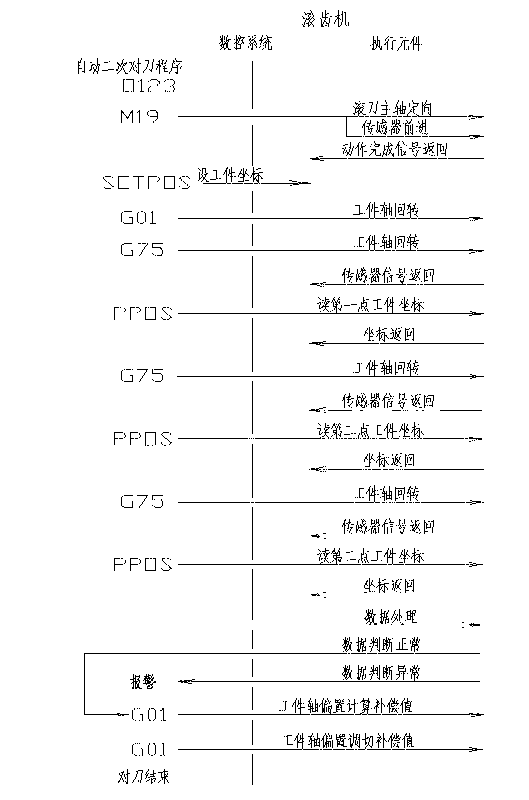

Automatic secondary tool setting method based on numerically-controlled gear hobbing machine

A secondary tool setting and automatic technology, applied in the direction of automatic control devices, metal processing machinery parts, metal processing, etc., to achieve the effect of simple operation, improved reliability, and shortening the time of secondary tool setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

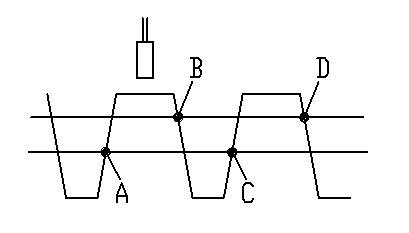

[0025] First of all, the intelligent measurement sensor device is used for data collection for a single teeth for the measured gear, and calculated through the number of teeth and collected signals of the measured gear to establish a measuring mathematical model;Low signal parameters; finally set the compensation angle through the first workpiece trial cutting result.This method can be used to realize the automatic two -time knife of the tooth and axis tooth. At the same time, the sensor selection and the high and low point setting methods and points of the amplifier can be clearly used to automatically apply the knife to the gear of different specifications.

[0026] The invention includes the use of the measurement function of the CNC system, the automatic control of the knife, the calculation, the math judgment model, the processing program, and the parameter setting of the amplifier.Before starting a gear for secondary processing, the user needs to adjust the measurement of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com