Cu-Mn-Fe-Cr cobalt-free black ceramic pigment and preparation method thereof

A technology of cu-mn-fe-cr and black ceramic pigment, which is applied in the field of ceramic color glaze, can solve the problems of unsatisfactory application requirements, poor application performance, complicated operation, etc., and is conducive to large-scale promotion and application , easy to control and realize, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

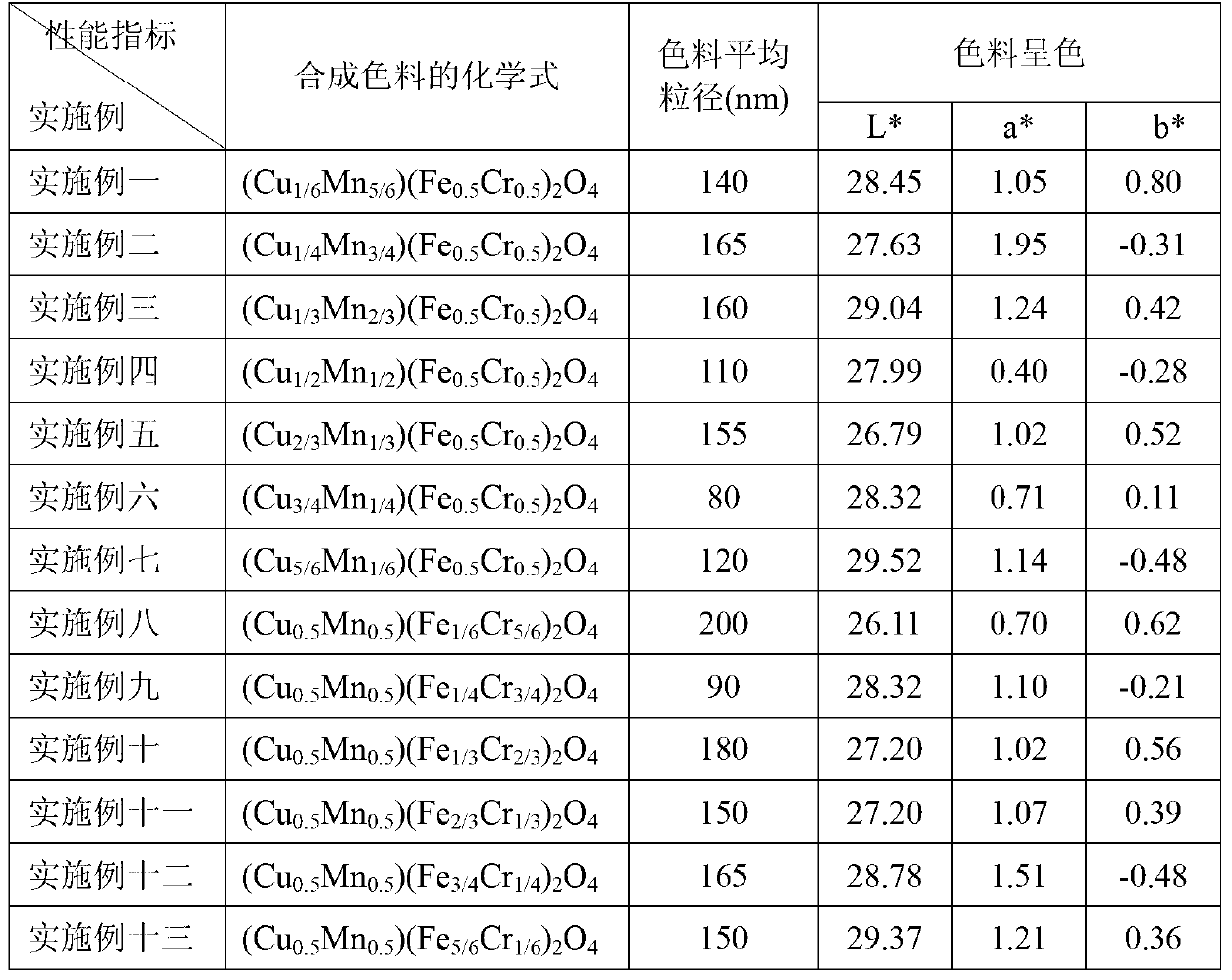

Examples

Embodiment 1

[0029] The preparation method of the present embodiment Cu-Mn-Fe-Cr cobalt-free black ceramic pigment, its steps are as follows:

[0030] (1) according to the parameter in above-mentioned chemical reaction formula and table 1, take copper nitrate, manganese nitrate, ferric nitrate, chromium nitrate respectively by respective stoichiometric ratio, citric acid is weighed by 200wt% of its stoichiometric ratio, chlorine Potassium chloride according to the synthetic product (Cu 1 / 6 mn 5 / 6 ) (Fe 0.5 Cr 0.5 ) 2 o 4 Weigh 50wt% of the theoretical synthesis amount; dissolve each raw material in distilled water, and stir magnetically for 60 minutes to mix evenly, and Cu in the mixed solution 2+ +Mn 2+ The ion concentration is 0.2mol / L;

[0031] (2) Put the above mixed solution in a heat-resistant crucible, ignite and burn it in a muffle furnace at a temperature of 400 ° C, and keep it warm for 15 minutes after burning to obtain a product precursor;

[0032] (3) The precursor of ...

Embodiment 2

[0035]The preparation method of the present embodiment Cu-Mn-Fe-Cr cobalt-free black ceramic pigment, its steps are as follows:

[0036] (1) according to the parameter in above-mentioned chemical reaction formula and table 1, take copper nitrate, manganese nitrate, ferric nitrate, chromium nitrate respectively by respective stoichiometric ratio, citric acid weighs by its 150wt% by stoichiometric ratio, Potassium chloride (Cu 1 / 4 mn 3 / 4 )(Fe 0.5 Cr 0.5 ) 2 o 4 30wt% of the theoretical synthesis amount was weighed; each raw material was dissolved in distilled water, and magnetically stirred for 30 minutes to mix evenly, and Cu in the mixed solution 2+ +Mn 2+ The ion concentration is 0.3mol / L;

[0037] (2) Put the above mixed solution in a heat-resistant crucible, ignite and burn it in a muffle furnace at a temperature of 300°C, and keep it warm for 20 minutes after burning to obtain a product precursor;

[0038] (3) The precursor of the above product was calcined at a te...

Embodiment 3

[0041] The preparation method of the present embodiment Cu-Mn-Fe-Cr cobalt-free black ceramic pigment differs from Example 1 in that:

[0042] In step (1), each raw material is dissolved in distilled water, and magnetically stirred for 30 minutes to mix evenly, and Cu in the mixed solution 2+ +Mn 2+ The ion concentration is 0.5mol / L;

[0043] In step (3), the product precursor is calcined at a temperature of 1200° C., kept for 60 minutes, and cooled with the furnace to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com