Novel method for removing protein impurities in groups A, C meningococcal capsular polysaccharide

A technology of meningococcal and capsular polysaccharides, which is applied to protein impurities in the capsular polysaccharides of group C meningococci and removes the A field, which can solve the problems of high cost, great harm, and incapability of large-scale production, and achieve low production costs , simple operation, suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

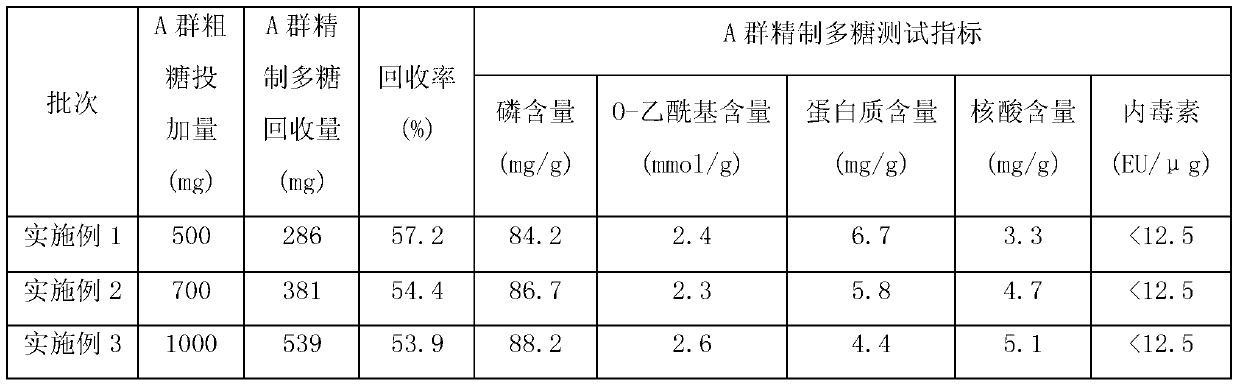

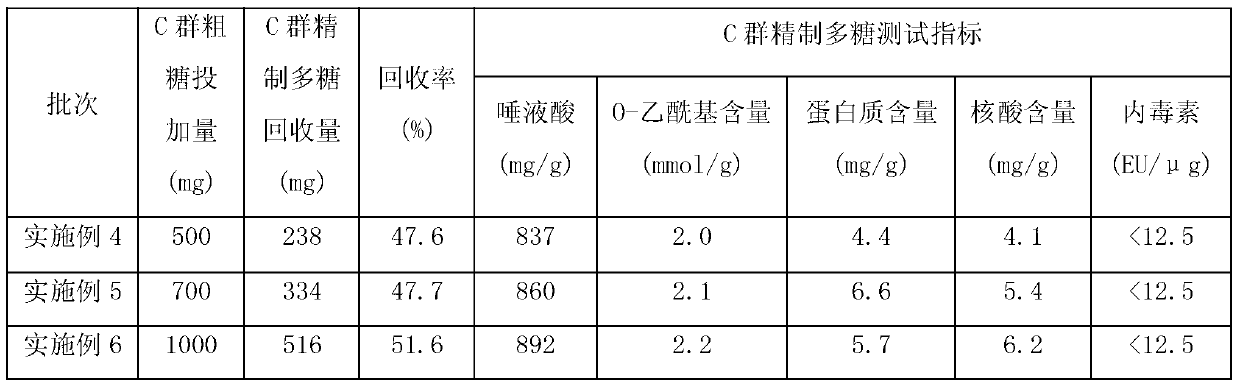

Embodiment 1

[0013] Embodiment 1: the new method of removing protein impurity in the capsular polysaccharide of group A meningococcus, it comprises the following steps:

[0014] S1. Dissolve 500 mg of the crude Group A epidemic cerebrospinal meningitis capsular polysaccharide with water for injection, dilute it into a polysaccharide solution of 5 mg / ml, add 2%, sodium deoxycholate solution of pH8.0, and the volume ratio is 0.5: 1. Mix well and stir at 2°C for 0.5h;

[0015] S2. Adjust the pH to 2 with 1mol / L hydrochloric acid, stir at 2°C for 3min, and then centrifuge at 8000rpm for 1.5h;

[0016] S3. Take the supernatant, adjust the pH to 7 with 1mol / L sodium hydroxide, and repeat steps S1 and S2 once;

[0017] S4. Take the supernatant, adjust the pH to 7 with 1mol / L sodium hydroxide, dilute 5 times with water for injection, ultrafilter to the original volume through a 250kd ultrafiltration membrane, repeat dilution, ultrafiltration concentration twice, and the last ultrafiltration conce...

Embodiment 2

[0018] Embodiment 2: the new method of removing protein impurity in the capsular polysaccharide of group A meningococci, it comprises the following steps:

[0019] S1. Dissolve 700 mg of crude Group A epidemic cerebrospinal meningitis capsular polysaccharide with water for injection, dilute it into a polysaccharide solution of 10 mg / ml, add 2%, sodium deoxycholate solution of pH8.0, and the volume ratio is 1.5: 1. Mix well and stir at 6°C for 1.5h;

[0020] S2. Adjust the pH to 3 with 1mol / L hydrochloric acid, stir at 6°C for 7min, and then centrifuge at 8000rpm for 1.5-2.5h;

[0021] S3. Take the supernatant, adjust the pH to 7 with 1mol / L sodium hydroxide, and repeat steps S1 and S2 once;

[0022] S4. Take the supernatant, adjust the pH to 7 with 1mol / L sodium hydroxide, dilute 15 times with water for injection, ultrafilter to the original volume through a 350kd ultrafiltration membrane, repeat dilution, ultrafiltration concentration 5 times, and the last ultrafiltration co...

Embodiment 3

[0023] Embodiment 3: the new method of removing protein impurity in the capsular polysaccharide of group A meningococci, it comprises the following steps:

[0024] S1. Dissolve 1000 mg of crude Group A meningococcal meningitis capsular polysaccharide with water for injection, dilute it into a polysaccharide solution of 8 mg / ml, add 2%, sodium deoxycholate solution of pH8.0, and the volume ratio is 1: 1. Mix well and stir at 4°C for 1 hour;

[0025] S2. Adjust the pH to 2 with 1mol / L hydrochloric acid, stir at 4°C for 5min, and then centrifuge at 8000rpm for 2h;

[0026] S3. Take the supernatant, adjust the pH to 7 with 1mol / L sodium hydroxide, and repeat steps S1 and S2 once;

[0027] S4. Take the supernatant, adjust the pH to 7 with 1mol / L sodium hydroxide, dilute 10 times with water for injection, ultrafilter to the original volume through a 300kd ultrafiltration membrane, repeat dilution, ultrafiltration concentration 3 times, and the last ultrafiltration concentration to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com