Low-temperature engineering steel with yield strength not lower than 550MPa and production method of engineering steel

A low-temperature engineering and yield strength technology, which is applied to low-temperature engineering steel with yield strength ≥ 550MPa and its production field, can solve the problems of low strength impact toughness, low alloy elements, and easy cracks, etc., and achieve excellent low temperature impact toughness, production The effect of simple process and uniform tissue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

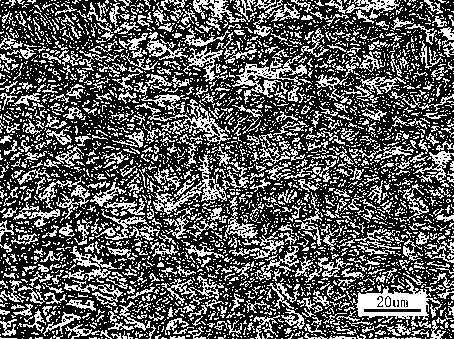

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below:

[0020] The test of the present invention adopts 130t converter smelting and pouring into a continuous casting billet of 250-300mm×1600-2000mm×L, and adopts TMCP process for rolling test.

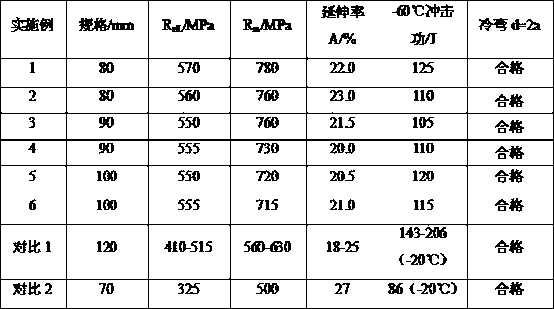

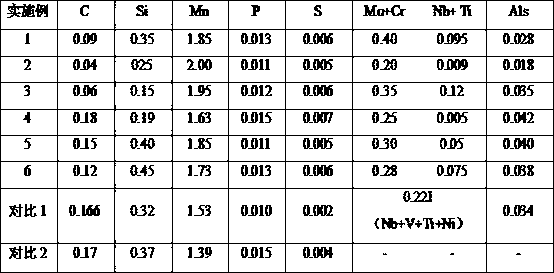

[0021] Table 1 is a list of values of various embodiments and comparative examples of the present invention;

[0022] Table 2 is a list of main process parameters of each embodiment and comparative example of the present invention;

[0023] Table 3 is a list of performance monitoring conditions of various embodiments and comparative examples of the present invention.

[0024] The embodiments of the present invention are produced according to the following steps:

[0025] 1) Smelting and continuous casting into billets;

[0026] 2) Heating the slab, controlling the heating temperature at 1150~1200℃;

[0027] 3) Adopt TMCP segmented rolling: control the first-stage start-rolling temperature at 1050~1120℃. The cumulative reduction rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com