Low-sugar coarse grain soft sweet and preparation method thereof

A production method and technology for coarse grains, which are applied in confectionery, confectionery industry, food science and other directions, can solve the problems of unfavorable fudge moisture evaporation, decline in edible quality, and decline in flavor quality of final products, and achieve solutions to aging and prolongation of shelf life. Shelf life, superior water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

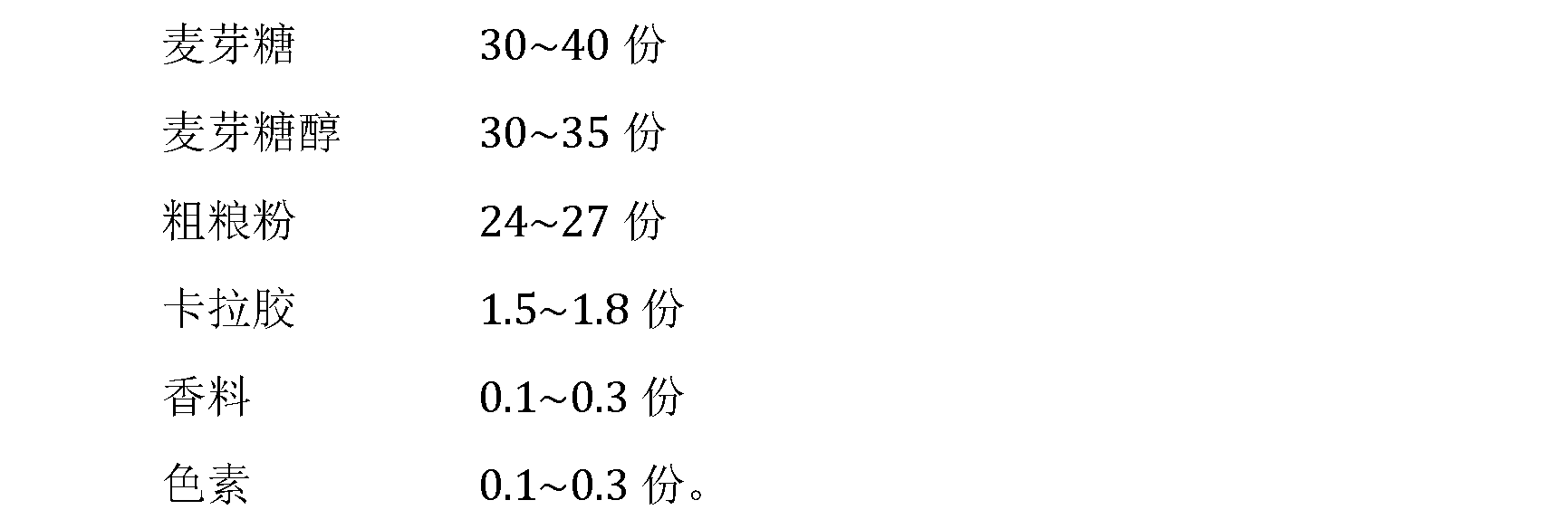

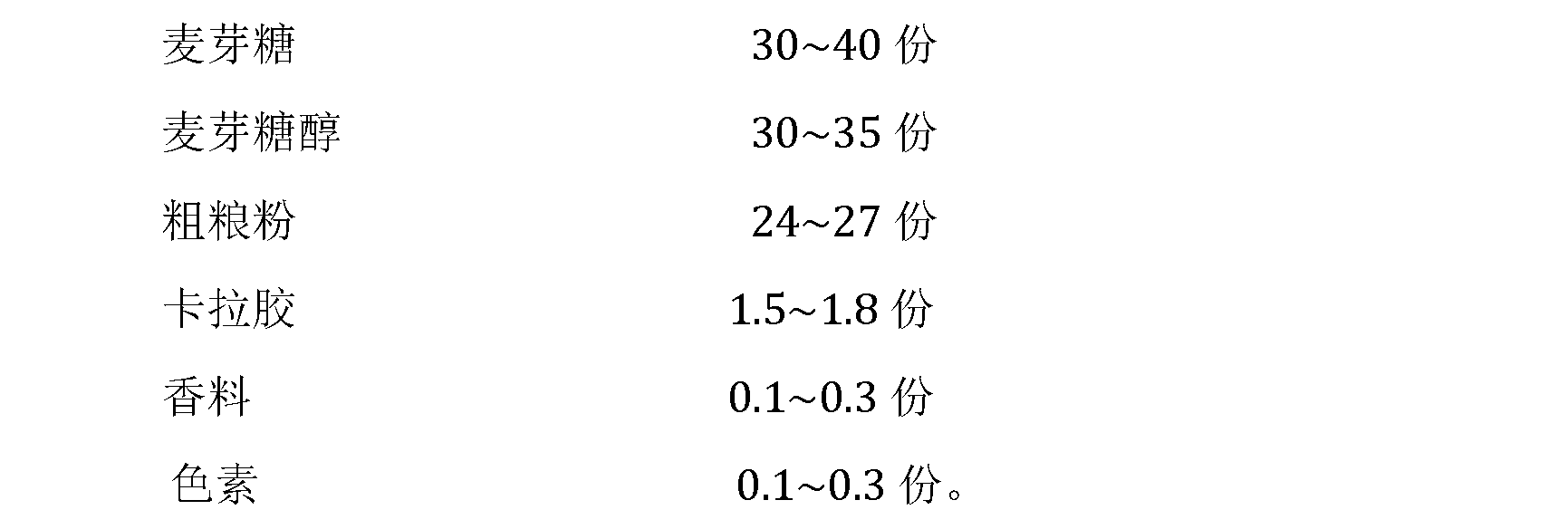

[0037] The preparation of embodiment 1 sweet potato jelly

[0038] 1. Preparation of Sweet Potato Suspension

[0039] Prepare sweet potato suspension with 24 parts of sweet potato powder and 120 parts of water, set aside;

[0040] 2. Sol

[0041] Prepare sol with 1.5 parts of carrageenan and 19.5 parts of water, set aside;

[0042] 3. Dissolving sugar

[0043] Add 30 parts of maltitol and 15 parts of water into the sugar pot, heat until the sugar alcohol dissolves, then add 30 parts of maltose, mix well, and set aside;

[0044] 4. Boil

[0045] After dissolving the above-mentioned sugar alcohol solution and maltose, add the above-mentioned carrageenan sol, mix evenly and boil, when the syrup is boiled to boiling, add the sweet potato suspension and continue to boil for 10 minutes;

[0046] 5. Pouring molding

[0047] Continue to boil the boiled sugar solution at a temperature of 102°C. When the material liquid turns into a translucent paste, stop heating, add 0.1 part of...

Embodiment 2

[0053] Embodiment 2 Preparation of corn fudge

[0054] 1. Preparation of Corn Suspension

[0055] Prepare corn suspension with 25.5 parts of corn flour and 127.5 parts of water, set aside;

[0056] 2. Sol

[0057] Prepare sol with 1.65 parts of carrageenan and 21.45 parts of water, set aside;

[0058] 3. Dissolving sugar

[0059] Add 32.5 parts of maltitol and 16.25 parts of water into the sugar pot, heat until the sugar alcohol dissolves, then add 35 parts of maltose, mix well, and set aside;

[0060] 4. Boil

[0061] After dissolving the above-mentioned sugar alcohol solution and maltose, add the above-mentioned carrageenan sol, mix well and boil, when the syrup is boiled to boiling, add the corn suspension and continue to boil for 12 minutes;

[0062] 5. Pouring molding

[0063] Continue to boil the boiled sugar solution at a temperature of 102°C. When the liquid turns into a translucent paste, stop heating, add 0.2 parts of the dissolved spices and 0.2 parts of the p...

Embodiment 3

[0069] The preparation of embodiment 3 soybean and mung bean jelly

[0070] 1. Preparation of soybean and mung bean suspensions

[0071] Prepare a suspension with 20 parts of soybean powder, 7 parts of mung bean powder and 135 parts of water, and set aside;

[0072] 2. Sol

[0073] Prepare sol with 1.8 parts of carrageenan and 23.4 parts of water, set aside;

[0074] 3. Dissolving sugar

[0075]Add 35 parts of maltitol and 17.5 parts of water into the sugar pot, heat until the sugar alcohol dissolves, then add 40 parts of maltose, mix well, and set aside;

[0076] 4. Boil

[0077] After dissolving the above-mentioned sugar alcohol solution and maltose, add the above-mentioned carrageenan sol, mix well and boil, when the syrup is boiled to boiling, add the above-mentioned suspension, and continue to boil for 15 minutes;

[0078] 5. Pouring molding

[0079] Continue boiling the boiled sugar solution at a temperature of 102°C. When the material liquid becomes a translucent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com