Recovery method and device for glyphosate raw material methanol

A recovery device and glyphosate technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of hydroxyl compounds, etc., can solve problems such as low methanol content, high pressure, and impact on methanol content, and achieve improved content and increase the condensation area, the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

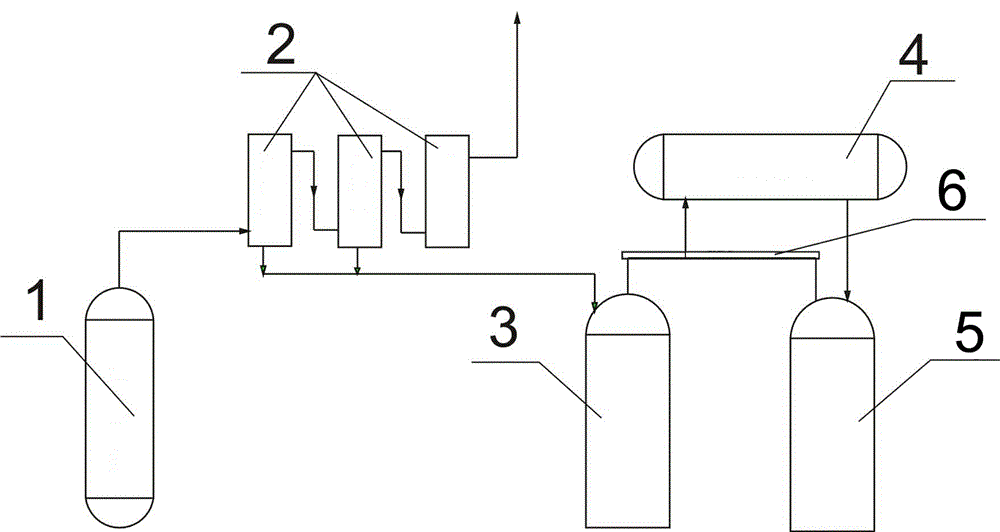

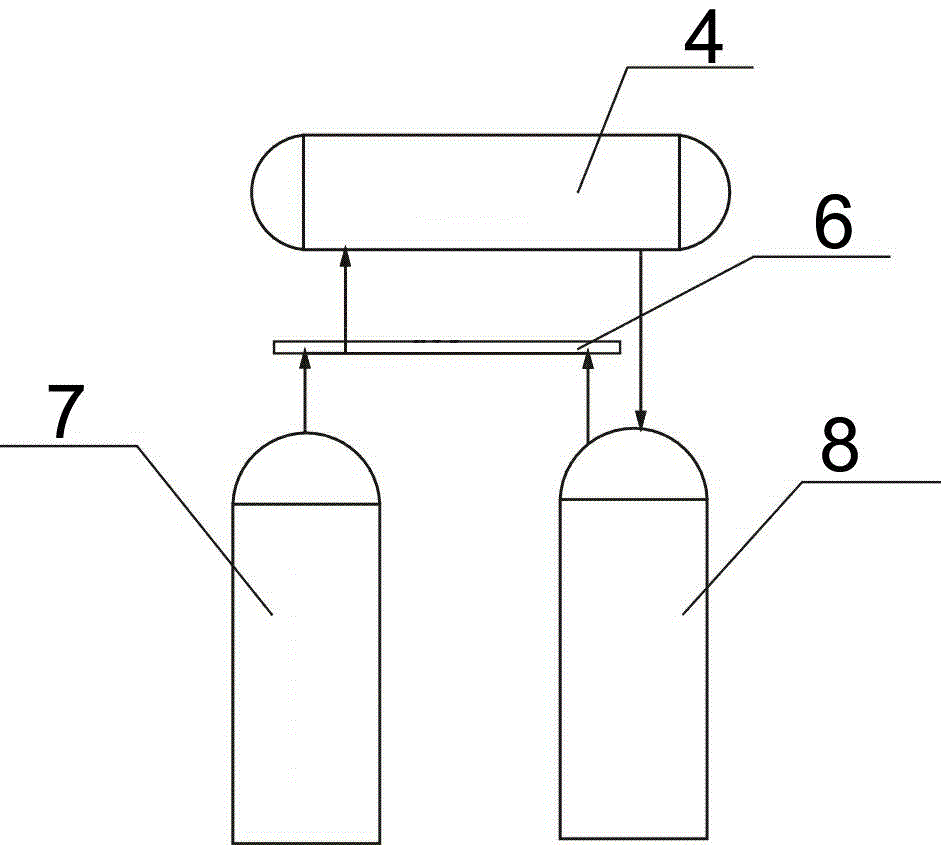

[0013] The mixed gas of methanol and methylal evaporated in the dealcoholization process of the glyphosate dealcoholization kettle undergoes three-stage condensation, and after the methanol and methylal are liquefied, they are collected into the dilute methanol storage tank and recovered in the methanol rectification post. The dilute methanol storage tank and the vent pipe of the reflux methylal are combined and passed into the -10°C refrigerated brine condenser, and the condensate flows into the methylal return tank; the finished methanol storage tank and the vent pipe of the methanol return tank are combined and then passed through into the 2°C brine condenser, and the condensate flows into the methanol return tank, which increases the heat transfer area and condensation effect of the condenser. Using this technology, the methanol content increases by 0.4%, the recovery rate of methylal increases by 12kg / t, and glyphosate The yield increased by 0.43%.

Embodiment 2

[0015] The mixed gas of methanol and methylal evaporated in the dealcoholization process of the glyphosate dealcoholization kettle undergoes three-stage condensation, and after the methanol and methylal are liquefied, they are collected into the dilute methanol storage tank and recovered in the methanol rectification post. The dilute methanol storage tank and the vent pipe of returning methylal are combined and then passed into the -15°C frozen brine condenser, and the condensate flows into the methylal return tank; the finished methanol storage tank and the vent pipe of the methanol return tank are combined and then passed through into the 0°C brine condenser, the condensate flows into the methanol reflux tank, which increases the heat transfer area and condensation effect of the condenser. Using this technology, the methanol content increases by 0.52%, the recovery rate of methylal increases by 15kg / t, and glyphosate The yield increased by 0.77%.

Embodiment 3

[0017] The mixed gas of methanol and methylal evaporated in the dealcoholization process of the glyphosate dealcoholization kettle undergoes three-stage condensation, and after the methanol and methylal are liquefied, they are collected into the dilute methanol storage tank and recovered in the methanol rectification post. The dilute methanol storage tank and the vent pipe of returning methylal are combined and passed into the -18°C frozen brine condenser, and the condensate flows into the methylal return tank; the finished methanol storage tank and the vent pipe of the methanol return tank are combined and then passed through into the 3°C brine condenser, and the condensate flows into the methanol reflux tank, which increases the heat transfer area and condensation effect of the condenser. Using this technology, the methanol content increases by 0.34%, and the recovery rate of methylal increases by 11.7kg / t. The phosphine yield increased by 0.61%.

[0018] Glyphosate raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com