Production method of resorcinol formaldehyde resin

A technology of resorcinol formaldehyde resin and resorcinol, which is applied in the production field of resorcinol formaldehyde resin, can solve the problems of long reaction period, high energy consumption, long time and the like, achieves good adhesion performance and improves production Efficiency, the effect of avoiding pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

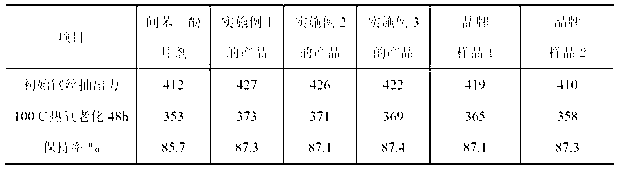

Examples

Embodiment 1

[0031] In a 500mL five-necked round-bottomed reaction flask equipped with a stirrer, reflux condenser and dropping funnel, add 110.0g (1mol) resorcinol and 2.4g composite catalyst, the mass ratio of oxalic acid and p-toluenesulfonic acid in the composite catalyst =1:9, heat to 110-120°C to melt, then quickly dropwise add 41.7g (0.4mol) styrene and 11.9g (0.15mol) formaldehyde aqueous solution within 20-30 minutes, keep warm and reflux for about 10 minutes, then The process maintains a temperature not higher than 130°C. Then add 10.4g (0.1mol) styrene and 39.5g (0.5mol) formaldehyde solution dropwise within 1 to 1.5 hours, keep warm and reflux for about 15 minutes, and keep the temperature not higher than 120°C during this process. Add 1.75g of sodium hydroxide solution to neutralize the composite catalyst, then stop stirring, wait for the organic phase and the water phase to separate, and extract the upper water phase. Finally, the temperature is raised to 125-150°C, and th...

Embodiment 2

[0033]In a 500mL five-necked round-bottomed reaction flask equipped with a stirrer, reflux condenser and dropping funnel, add 110.0g (1mol) resorcinol and 2.4g composite catalyst, the mass ratio of oxalic acid and p-toluenesulfonic acid in the composite catalyst =1:9, heat to 110-120°C to melt, then add 62.4g (0.6mol) styrene and 11.9g (0.15mol) formaldehyde solution dropwise quickly within 20-30 minutes, keep warm and reflux for about 10 minutes, then The process maintains a temperature not higher than 130°C. Then add 10.4g (0.1mol) styrene and 43.4g (0.55mol) formaldehyde solution dropwise within 1 to 1.5 hours, keep warm and reflux for about 15 minutes, and keep the temperature not higher than 120°C during this process. Add 1.75g of sodium hydroxide solution to neutralize the composite catalyst, then stop stirring, wait until the organic phase and the water phase are separated, extract the upper water phase, and finally raise the temperature to 125-150°C, distill under re...

Embodiment 3

[0035] In a 500mL five-necked round-bottom reaction flask equipped with a stirrer, reflux condenser and dropping funnel, add 220.0g (2mol) resorcinol and 4.8g composite catalyst, the mass ratio of oxalic acid and p-toluenesulfonic acid in the composite catalyst =1:7.5, heat to 110-120°C to melt, then quickly dropwise add an aqueous solution of 104.1g (1mol) styrene and 15.7g (0.2mol) formaldehyde within 20-30 minutes, keep warm and reflux for about 10 minutes, this process Keep the temperature not higher than 130°C. Then add 62.4g (0.6mol) styrene and 47.2g (0.6mol) formaldehyde solution dropwise within 1 to 1.5 hours, keep the temperature under reflux for about 15 minutes, and keep the temperature not higher than 120°C during this process. Add 1.8g of sodium hydroxide solution to neutralize the composite catalyst, then stop stirring, wait until the organic phase and the water phase are separated, take out the upper water phase, and finally raise the temperature to 125-150°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com