Ethylene propylene diene monomer rubber for automobile brake hose and preparation method thereof

A technology of EPDM rubber and automobile brake hose is applied in the field of preparation of EPDM rubber to achieve the effects of improving blast resistance, high ozone resistance and weathering resistance, and excellent ozone resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

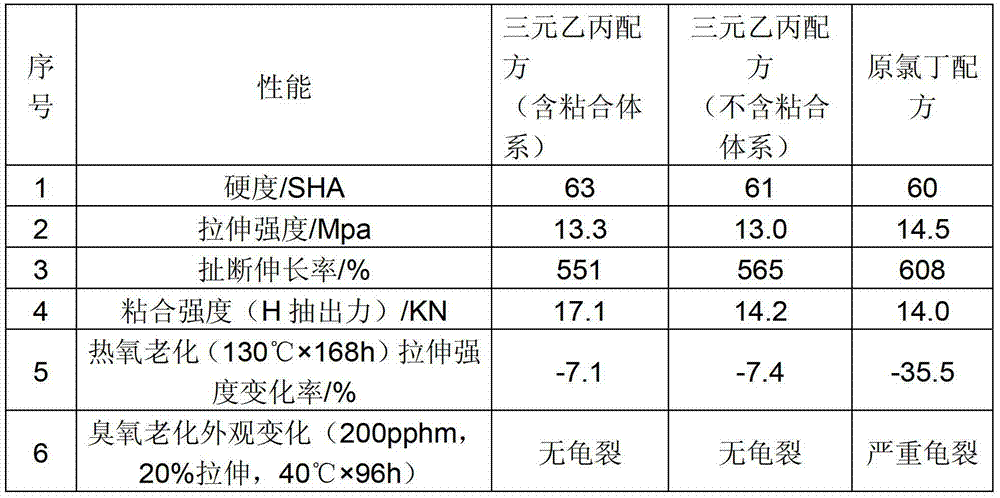

Image

Examples

Embodiment Construction

[0037] The preparation technology of the EPDM rubber for automobile brake hoses of the present invention will be further described in detail below through specific examples. Those skilled in the art can refer to the formulas and preparation methods of the examples to prepare automobile brake hoses. EPDM rubber, but should not be construed as any limitation of the invention.

[0038] The present invention will be described in detail below through specific examples.

[0039] Product name: EPDM rubber for automobile brake hose.

[0040] Formula: formula unit is parts by weight.

[0041] Table 1 Basic raw materials of rubber formula

[0042] serial number

Component

Example 1

Example 2

Example 3

Example 4

Example 5

1

EP350

100.0

100.0

100.0

100.0

100.0

2

S

0.5

0.8

1.0

1.5

1.8

3

DCP

2.0

1.5

1.0

0.8

0.5

4

DM

0.6

0.8

1.0

1.4

1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com