Transparent flame-retardant antistatic ABS material, and preparation method and application thereof

An ABS material, flame retardant and antistatic technology, applied in the field of polymer materials, can solve the problems of losing the aesthetic value of appearance, etc., and achieve the effect of simple and easy preparation method, excellent weather resistance and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

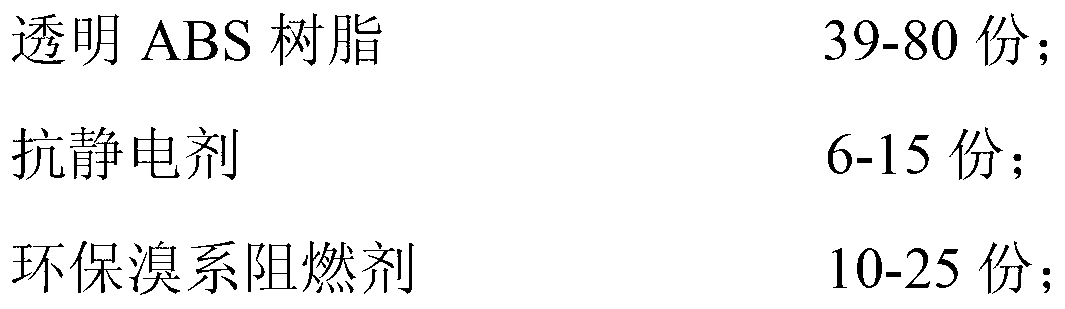

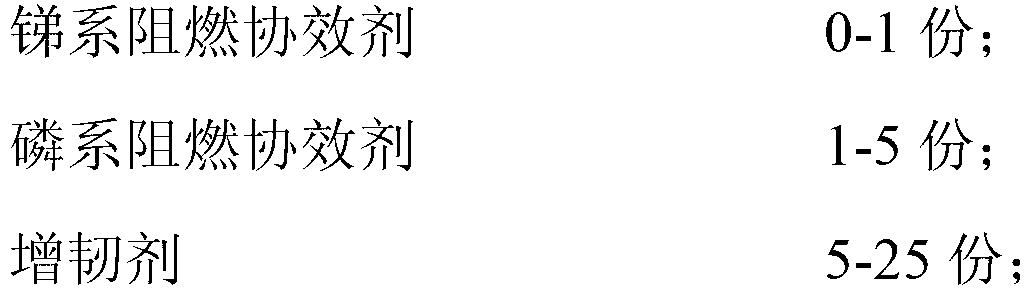

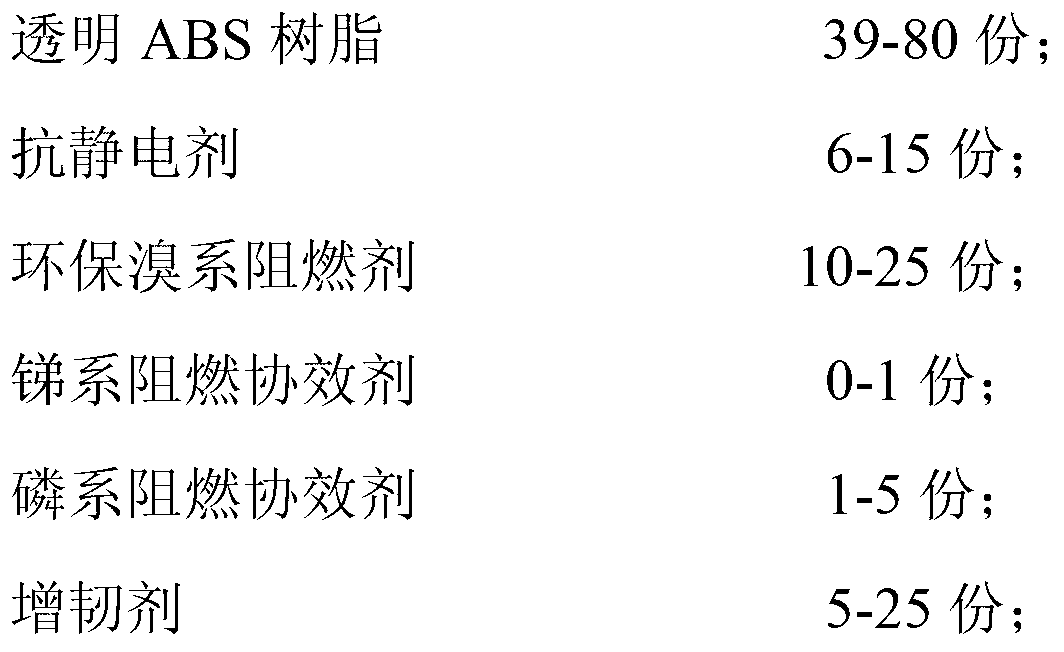

Method used

Image

Examples

Embodiment 1-4、 comparative example 1-4

[0061] According to the parts by weight listed in Table 2, each component is added into a high-speed mixer for uniform mixing, and then the above-mentioned mixture is sent into a twin-screw extruder for kneading, extrusion, stranding, water cooling, and pelletizing; wherein, The length-diameter ratio of the twin-screw extruder is 25-40; the temperature of the screw barrel is set as follows: the temperature of the first zone is 180°C, the temperature of the second zone is 190°C, the temperature of the third zone is 200°C, the temperature of the fourth zone is 210°C, and the temperature of the fifth zone is 220°C , the temperature of the sixth zone is 220°C, the temperature of the seventh zone is 220°C, the temperature of the eighth zone is 220°C, the temperature of the ninth zone is 220°C, the temperature of the tenth zone is 220°C, the temperature of the head is 230°C; the screw speed is 200-800 rpm.

[0062] The ABS material prepared by the above method was subjected to the pe...

Embodiment 5-9、 comparative example 6

[0068] According to the parts by weight listed in Table 3, each component is added into a high-speed mixer for uniform mixing, and then the above-mentioned mixture is sent into a twin-screw extruder for kneading, extrusion, stranding, water cooling, and pelletizing; wherein, The length-diameter ratio of the twin-screw extruder is 25-40; the temperature of the screw barrel is set as follows: the temperature of the first zone is 180°C, the temperature of the second zone is 190°C, the temperature of the third zone is 200°C, the temperature of the fourth zone is 210°C, and the temperature of the fifth zone is 220°C , the temperature of the sixth zone is 220°C, the temperature of the seventh zone is 220°C, the temperature of the eighth zone is 220°C, the temperature of the ninth zone is 220°C, the temperature of the tenth zone is 220°C, the temperature of the head is 230°C; the screw speed is 200-800 rpm.

[0069] The ABS material prepared by the above method was subjected to the pe...

Embodiment 10-18

[0076] According to the parts by weight listed in Table 4, each component is added into a high-speed mixer for uniform mixing, and then the above-mentioned mixture is sent into a twin-screw extruder for mixing, extrusion, stranding, water cooling, and pelletizing; wherein, The length-diameter ratio of the twin-screw extruder is 25-40; the temperature of the screw barrel is set as follows: the temperature of the first zone is 180°C, the temperature of the second zone is 190°C, the temperature of the third zone is 200°C, the temperature of the fourth zone is 210°C, and the temperature of the fifth zone is 220°C , the temperature of the sixth zone is 220°C, the temperature of the seventh zone is 220°C, the temperature of the eighth zone is 220°C, the temperature of the ninth zone is 220°C, the temperature of the tenth zone is 220°C, the temperature of the head is 230°C; the screw speed is 200-800 rpm.

[0077] The ABS material prepared by the above method was subjected to the perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com