Preparation method of borate modified phenolic foam material

A phenolic foam material and a borate ester technology, applied in the material field, can solve the problems of reduced flame retardant and fireproof performance of phenolic foam, reduced powder drop rate and the like, and achieve the effects of good flame retardant performance, reduced powder drop rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) put H 3 BO 3 Dissolve and disperse in polyethylene glycol: 60g PEG at room temperature under rapid mechanical stirring 200 6.2g H 3 BO 3 Disperse and dissolve.

[0019] (2) Polyethylene glycol is heated up to the preset temperature with H 3 BO 3 Esterification by molar ratio: the system is gradually heated up to 120°C, and the esterification reaction is carried out for 3 hours, polyethylene glycol and H 3 BO 3 The molar ratio is 3:1.

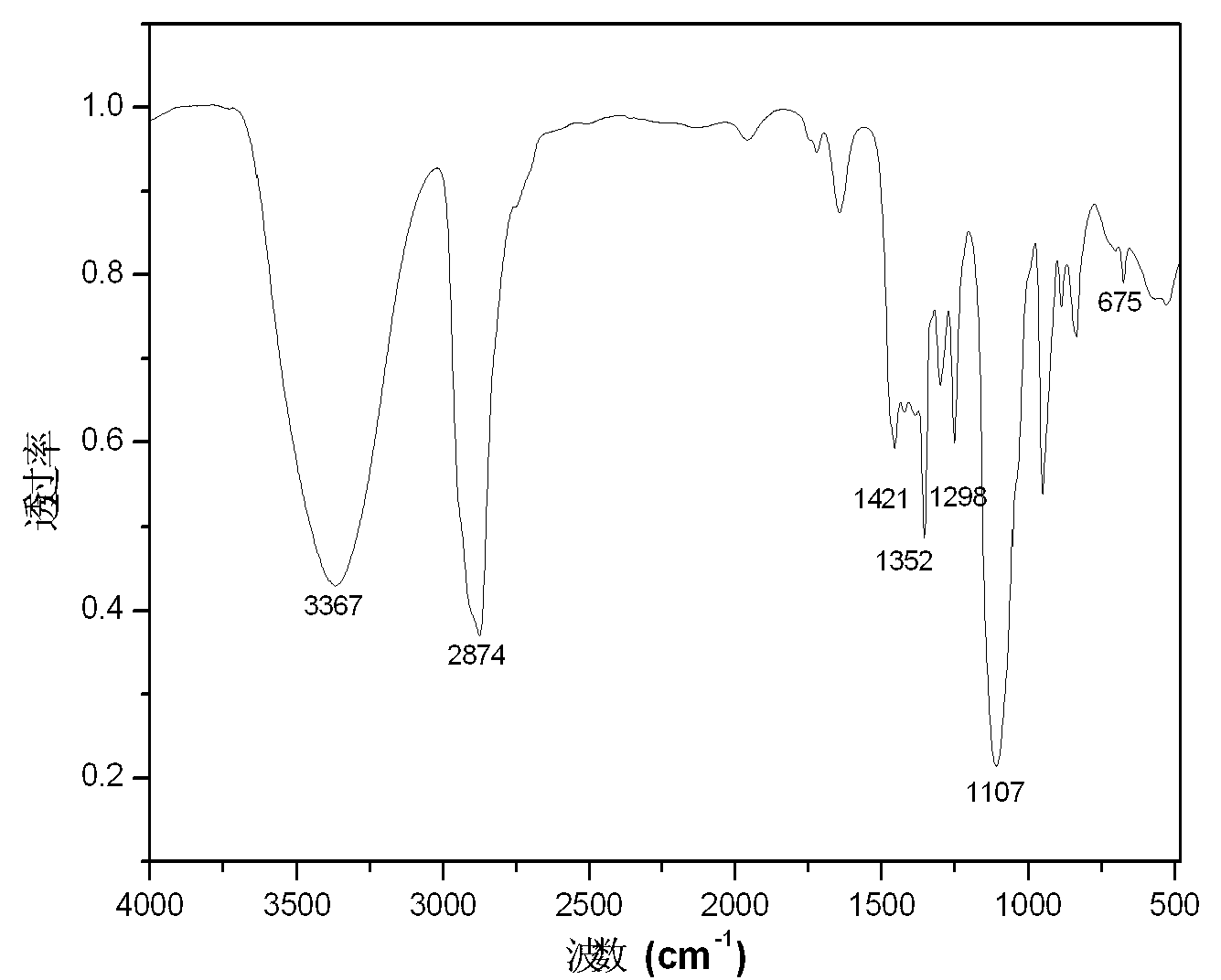

[0020] (3) The product is cooled to obtain the flame retardant modifier borate. The infrared spectrum of borate esters is shown in figure 1 as shown..

[0021] (4) Preparation of modified phenolic foam material

[0022] Add 8 parts by mass (100 parts by mass of resole phenolic resin) of flame retardant modifier to the resole phenolic resin, then add 5 parts by mass of Tween-80, 9 parts by mass of curing agent, 8 parts by mass of n-pentane The foaming agent was stirred and mixed evenly, and cured at 80°C for 50 minutes to...

Embodiment 2

[0024] (1) put H 3 BO 3 Dissolve and disperse in polyethylene glycol: 75g PEG at room temperature under rapid mechanical stirring 400 4g H 3 BO 3 Disperse and dissolve.

[0025] (2) Polyethylene glycol is heated up to the preset temperature with H 3 BO 3 Esterification reaction by molar ratio: gradually raise the temperature of the system to 130°C, carry out the esterification reaction for 2.5 hours, polyethylene glycol and H 3 BO 3 The molar ratio is 3:1.

[0026] (3) The product is cooled to obtain a flame retardant modifier.

[0027] (4) Preparation of modified phenolic foam material

[0028] Add 6 mass parts (100 mass parts of resole phenolic resin) flame retardant modifier to resole phenolic resin, then add 5 mass parts of Tween-80, 9 mass parts of curing agent, 8 mass parts of n-pentane hair The foaming agent was stirred and mixed evenly, and cured at 80°C for 50 minutes to prepare a modified phenolic resin foam material.

Embodiment 3

[0030] (1) put H 3 BO 3 Dissolve and disperse in polyethylene glycol: 65.6g PEG at room temperature under rapid mechanical stirring 400 3.5g H 3 BO 3 Disperse and dissolve.

[0031] (2) Polyethylene glycol is heated up to the preset temperature with H 3 BO 3 Esterification by molar ratio: The system is gradually heated up to 130°C, and the esterification reaction is carried out for 2 hours, polyethylene glycol and H 3 BO 3 The molar ratio is 3:1.

[0032] (3) The product is cooled to obtain the flame retardant modifier borate.

[0033] (4) Preparation of modified phenolic foam material

[0034] Add 4 mass parts (100 mass parts of resole phenolic resin) flame retardant modifier to resole phenolic resin, then add 5 mass parts of Tween-80, 9 mass parts of curing agent, 8 mass parts of n-pentane hair The foaming agent was stirred and mixed evenly, and cured at 80°C for 50 minutes to prepare a modified phenolic resin foam material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com