Underwater coating anti-pollution and anti-corrosion epoxy coating and preparation method thereof

An epoxy coating and anti-fouling technology, applied in anti-corrosion coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc. The effect of focusing, prolonging the cross-linking time, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0046] Example 1: White paint (for metal structures or concrete structures)

[0047] The anti-fouling and anti-corrosion epoxy coating for underwater coating is composed of A component and B component, and the weight ratio of the A component to the B component is 4:1;

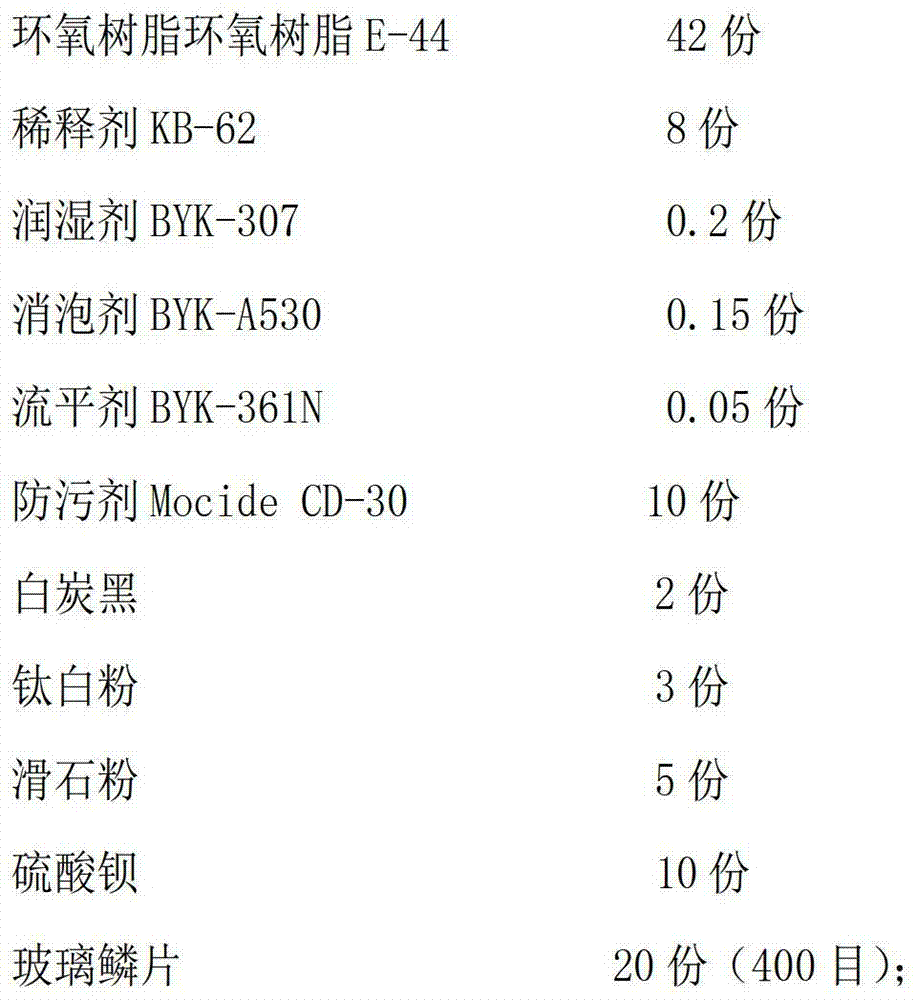

[0048] The A component includes the following components by weight:

[0049]

[0050] The B component includes the following components by weight:

[0051] 25 parts of curing agent 1085B, 0.75 parts of coupling agent KH5500, 2.5 parts of white carbon black.

[0052] The preparation method of the above-mentioned underwater coating antifouling and anticorrosion epoxy coating comprises the steps:

[0053] (1) Preparation of component A: Mix epoxy resin epoxy resin E-44, diluent KB-62, wetting agent BYK-307, defoamer BYK-A530 and leveling agent BYK-361N according to the stated ratio Pour into the mixing and dispersing kettle in turn, stir evenly at a speed of 600 rpm; add antifouling agent Mocide CD-30, stir ...

Embodiment 2

[0058] Example 2: brownish red (for metal structures)

[0059] The anti-fouling and anti-corrosion epoxy coating for underwater coating is composed of A component and B component, and the weight ratio of the A component to the B component is 4:1;

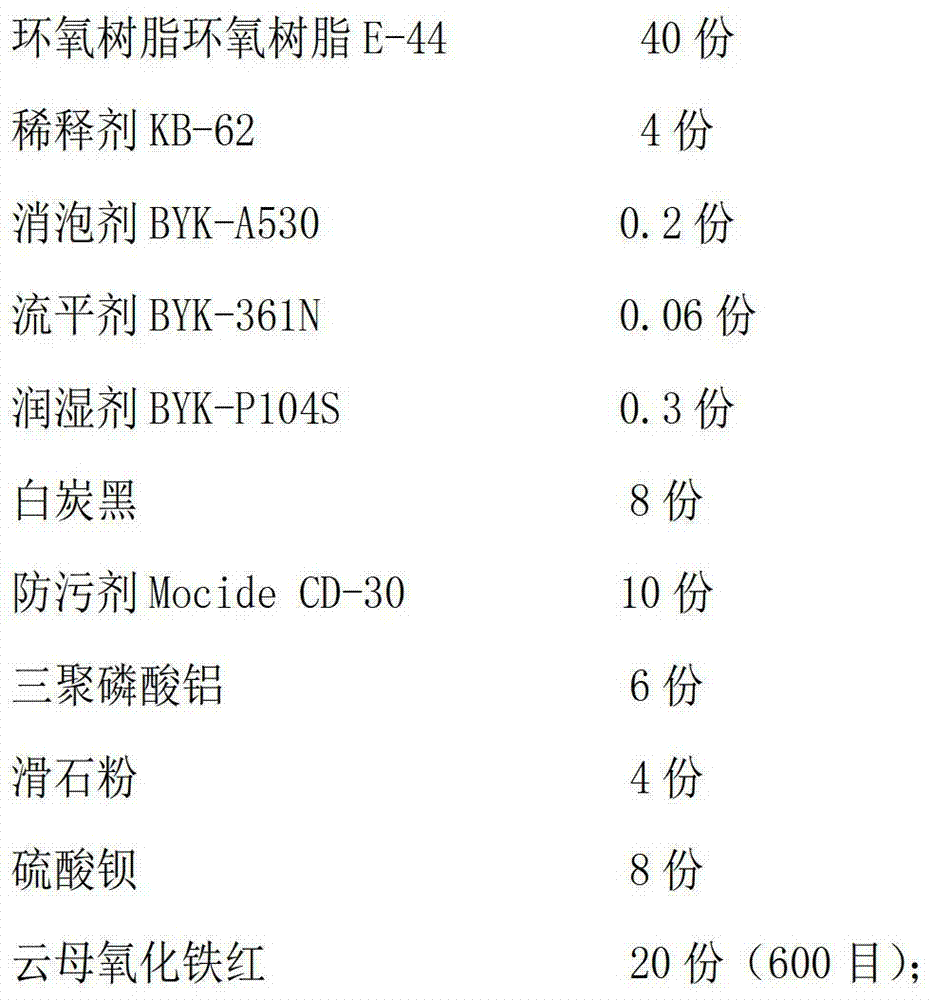

[0060] The A component includes the following components by weight:

[0061]

[0062] The B component includes the following components by weight:

[0063] 12 parts of curing agent 1085B, 13 parts of curing agent 1085C, 0.75 parts of coupling agent KH5500, 1.5 parts of white carbon black.

[0064] The preparation method of the above-mentioned underwater coating antifouling and anticorrosion epoxy coating comprises the steps:

[0065] (1) Preparation of component A: Mix epoxy resin epoxy resin E-44, diluent KB-62, wetting agent BYK-P104S, defoamer BYK-A530 and leveling agent BYK-361N according to the ratio Pour into the mixing and dispersing kettle in turn, stir evenly at a speed of 600 rpm; add antifouling agent Mocide CD-30, ...

Embodiment 3

[0070] Example 3: Yellow (for metal structures)

[0071] The anti-fouling and anti-corrosion epoxy coating for underwater coating is composed of A component and B component, and the weight ratio of the A component to the B component is 4:1;

[0072] The A component includes the following components by weight:

[0073]

[0074] The B component includes the following components by weight:

[0075] 25 parts of curing agent 1085C, 0.75 parts of coupling agent KH550, 2.5 parts of white carbon black.

[0076] The preparation method of the above-mentioned underwater coating antifouling and anticorrosion epoxy coating comprises the steps:

[0077] (1) Preparation of component A: Mix epoxy resin epoxy resin E-44, diluent KB-62, wetting agent BYK-P104S, defoamer BYK-A530 and leveling agent BYK-361N according to the ratio Pour into the mixing and dispersing kettle in turn, and stir evenly at a speed of 600 rpm; add antifouling agent Mocide88, and stir at a speed of 300 rpm for 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com