On-line detection device and on-line detection method of dye concentration in printing and dyeing process of connecting vat

A dye concentration and detection device technology, applied in the field of textile dyeing, can solve the problems of limited detection time resolution, unstable color, poor flexibility, etc. The effect of dye waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

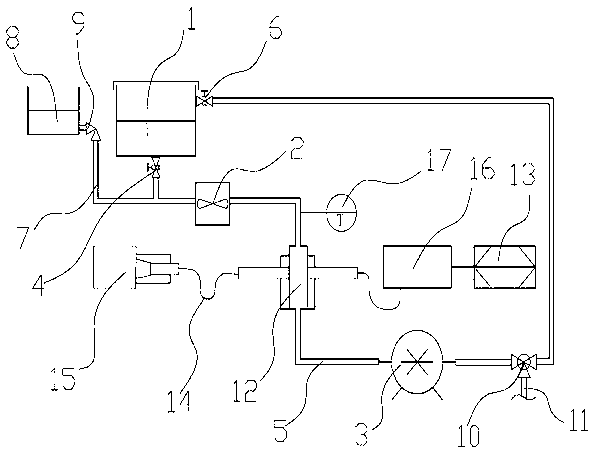

[0033] Such as figure 1 as shown, one An online detection device for dye concentration in the printing and dyeing process of continuous cylinders, including a dyeing cylinder 1, an outflow valve 4, a cooler 2, a spectral analysis system, a constant flow pump 3, a flow cell cuvette 12, a computer 13, a light source 15 and a spectrometer 16 , the dye vat 1, the outflow valve 4, the cooler 2, the flow cell cuvette 12 and the return valve 6 are connected in sequence through the pipeline 5 to form a loop, and the pipeline 5 between the outlet of the outflow valve 4 and the inlet of the cooler 2 A cleaning pipeline 7 is connected, the inlet of the cleaning pipeline 7 is connected to a water tank 8, an angle valve 9 is installed at the outlet of the water tank 8, and a thermometer 17 is installed on the pipeline 5 between the outlet of the cooler 2 and the upper inlet of the flow cell cuvette 12 , the light source 15 and the spectrometer 16 are respectively connected to both sides ...

Embodiment 2

[0046] The dye concentration online detection device in the continuous cylinder printing and dyeing process of this embodiment is the same as that of Embodiment 1, the difference is that the inner diameter of the pipeline 5, the cleaning pipeline 7 and the waste liquid discharge pipe 11 are all 0.9 mm, and the wall thickness is 1.2 mm. silicone rubber tubing.

[0047] The online detection method of dye concentration in the continuous cylinder printing and dyeing process of this embodiment is also the same as that of Embodiment 1, the difference is that in step (I), the cleaning is performed for 4 minutes, and the delivery flow rate of the constant flow pump 3 is 20ml / min.

Embodiment 3

[0049] The dye concentration online detection device in the continuous cylinder printing and dyeing process of this embodiment is the same as that of Embodiment 1, the difference is that the pipeline 5, the cleaning pipeline 7 and the waste liquid discharge pipe 11 are all with an inner diameter of 1 mm and a wall thickness of 1.5 mm. Silicone rubber tubing.

[0050] The online detection method of the dye concentration in the continuous cylinder printing and dyeing process of this embodiment is the same as that of Embodiment 1, the difference is that in step (I), cleaning is performed for 5 minutes, and the delivery flow rate of the constant flow pump 3 is 18ml / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com