Air cylinder cover and manufacturing method thereof

A technology of cylinder head and tubular parts, which is applied in the field of cylinder head and its manufacturing, can solve the problems of reducing the range of cooling water jacket of cylinder head, affecting the cooling effect of cylinder, hindering the flow of oil, etc. smooth flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

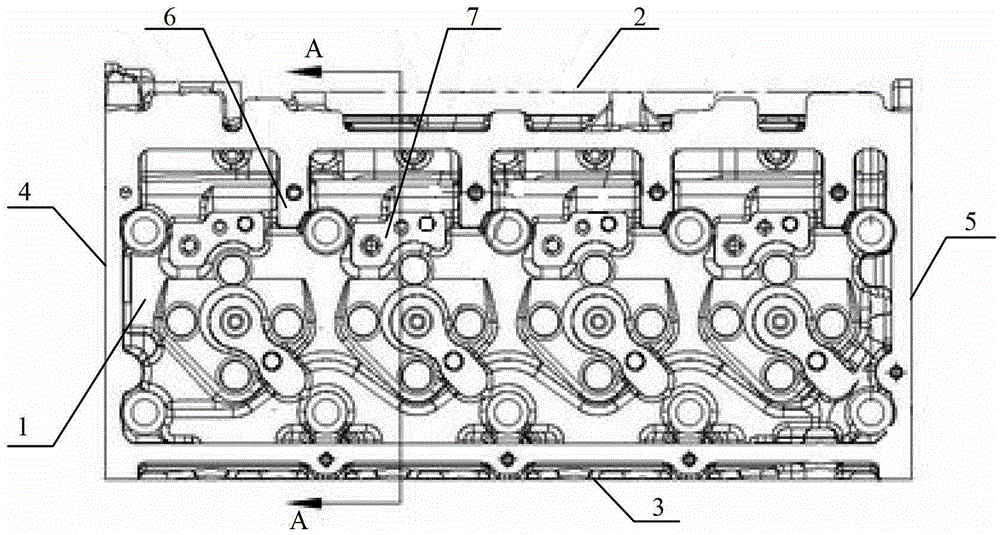

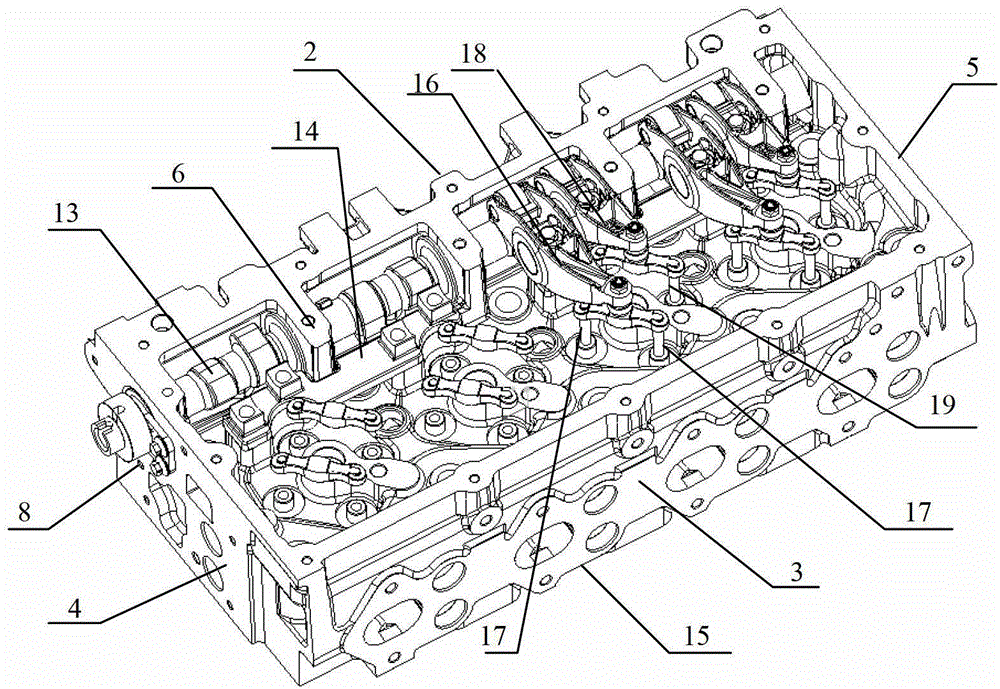

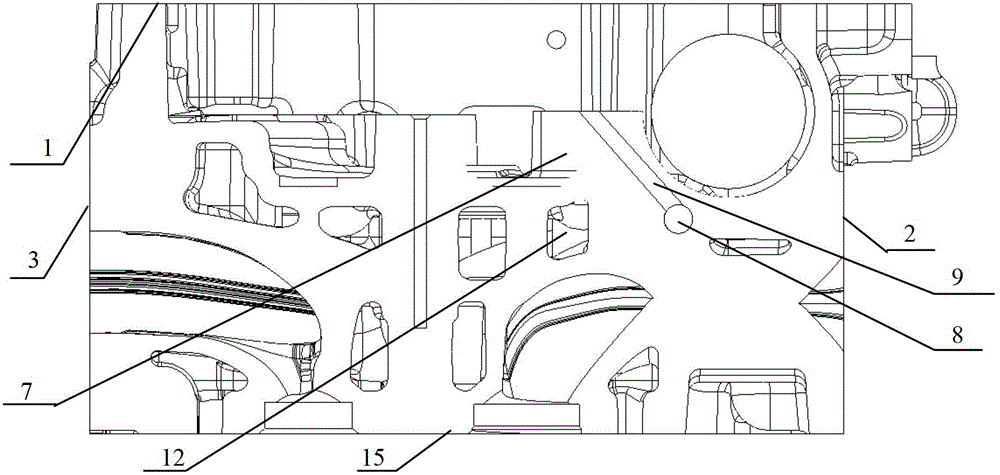

[0033] to combine figure 1 with figure 2 , the cylinder head has a top surface 1, a bottom surface 15 facing the cylinder block (not shown) and connected thereto, an intake side 2 with intake ports distributed, an exhaust side 3 with exhaust ports distributed, facing the timing train The front end face 4 and the rear end face 5 opposite to the front end face 4. Those of ordinary skill in the art should understand that the front end face 4 and the rear end face 5 are defined relative to the positions of the timing gear train, and of course other definition methods can also be used, such as exchanging the defined positions of the front and rear end faces. On the top surface 1, a camshaft mounting seat 6 is distributed, and a rocker arm support mounting boss 7 is distributed near it. The camshaft 13 is installed in the camshaft mounting seat 6, the rocker arm support 14 is installed on the rocker arm support installation boss 7, and the intake rocker arm 16 and the exhaust roc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com