Energy-saving flexible fireproof multi-core cable

A multi-core cable, energy-saving technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of increased cost, large outer diameter, large consumption, etc., and achieves improved production efficiency, increased surface area, and large load. The effect of traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

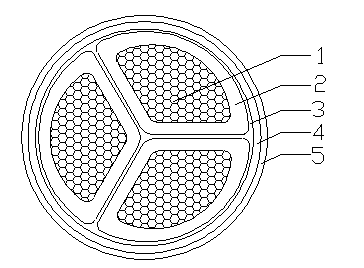

[0015] Such as figure 1 As shown, an energy-saving flexible fireproof multi-core cable according to the present invention includes a cable core, and the cable core is twisted by several fan-shaped insulated wire cores, and the fan-shaped insulated wire core is composed of fan-shaped conductors 1 and It consists of an insulating layer 2 extruded outside the fan-shaped conductor 1; a synthetic phlogopite tape 3 is wrapped around the cable core, and a patterned copper sheath 4 is longitudinally wrapped outside the synthetic phlogopite tape 3, in order to prevent the patterned sheath from being in contact with air for a long time Oxidative deterioration is caused, so a layer of low-smoke halogen-free polyolefin outer sheath 5 is extruded on the outside of the barbed copper sheath 4 by extrusion, and also serves as an oxygen barrier layer.

[0016] The above-mentioned fan-shaped conductor 1 is formed by twisting a plurality of oxygen-free copper monofilaments. When the fan-shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com