High-security phosphate-based electrolyte and lithium ion battery

A phosphate-based, high-safety technology, which is applied in the field of electrochemical and chemical power supply products, can solve the problems of graphite negative electrodes being difficult to be compatible, difficult to cycle stably, and poor compatibility, so as to improve compatibility, improve battery performance, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Electrolyte preparation

[0028] In an argon-protected glove box, the treated vinyl ethyl phosphate (EEP) and dimethyl methyl phosphate (DMMP) were mixed uniformly at a mass ratio of 1:1, and then a certain amount of lithium hexafluorophosphate ( LiPF6), shake well until the lithium salt is completely dissolved, and prepare an electrolyte solution with a concentration of 1mol / L, which is the flame-retardant electrolyte solution for lithium-ion batteries of the present invention.

[0029] 2) Electrolyte combustion test

[0030] Take out the above prepared electrolyte solution from the glove box, soak a cotton ball with a mass of 0.0100g and a diameter of about 3mm in the electrolyte solution, roll it on the filter paper after taking it out, remove the electrolyte solution on the surface, and control the cotton ball. quality, light it with an open flame, and test the extinguishing time of the cotton ball.

[0031] 3) Electrochemical performance test

[0032] Positiv...

Embodiment 2

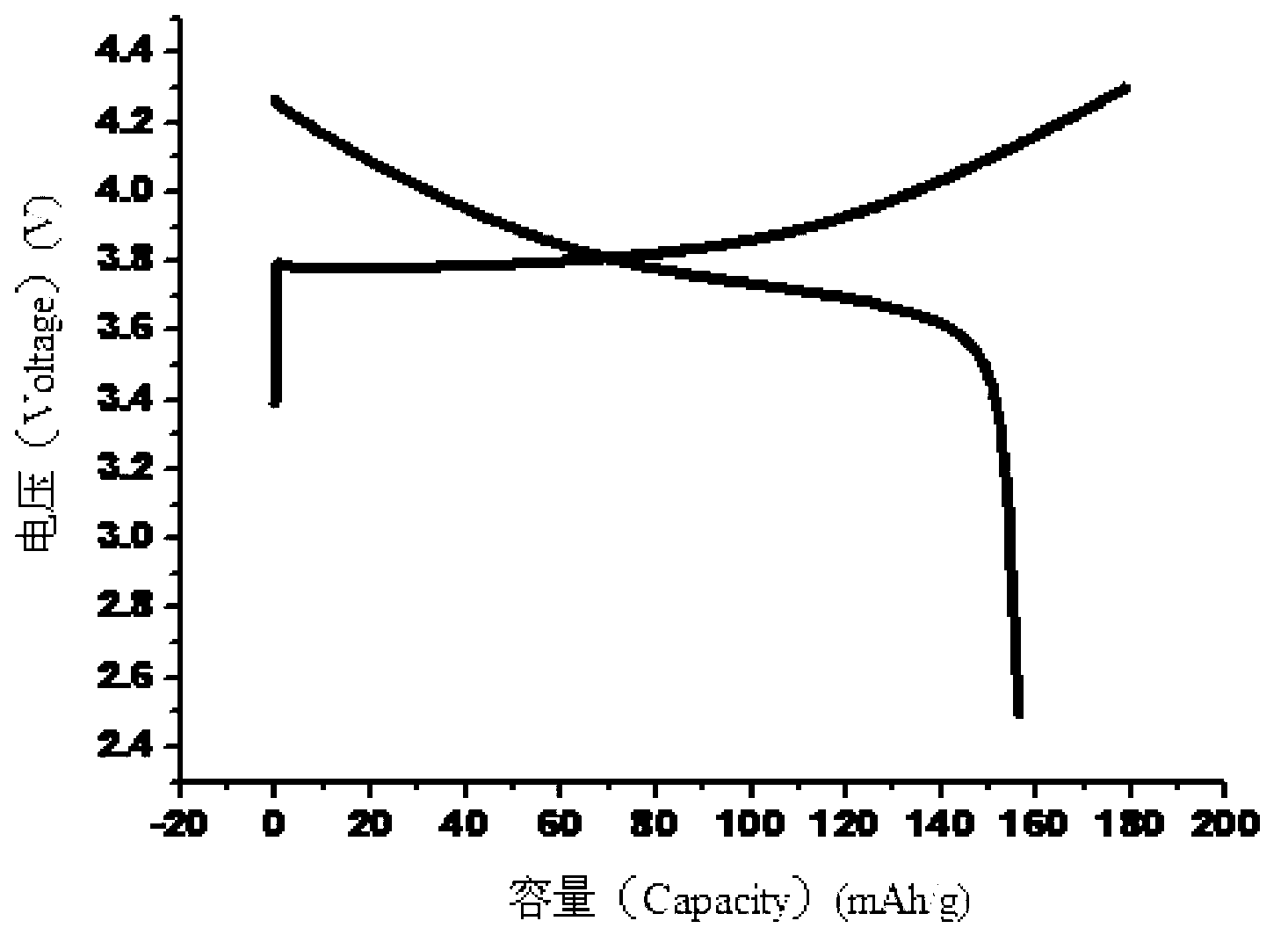

[0036] Repeat Example 1, the difference is that step 1) electrolyte preparation, chain phosphoric acid ester choose trimethyl phosphate (TMP), take vinyl ethyl phosphate (EEP) and trimethyl phosphate (TMP) The mass ratio is 1:0.5. image 3 is Example 2 in LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 / Li positive half-cell charge and discharge curves for the first time.

Embodiment 3

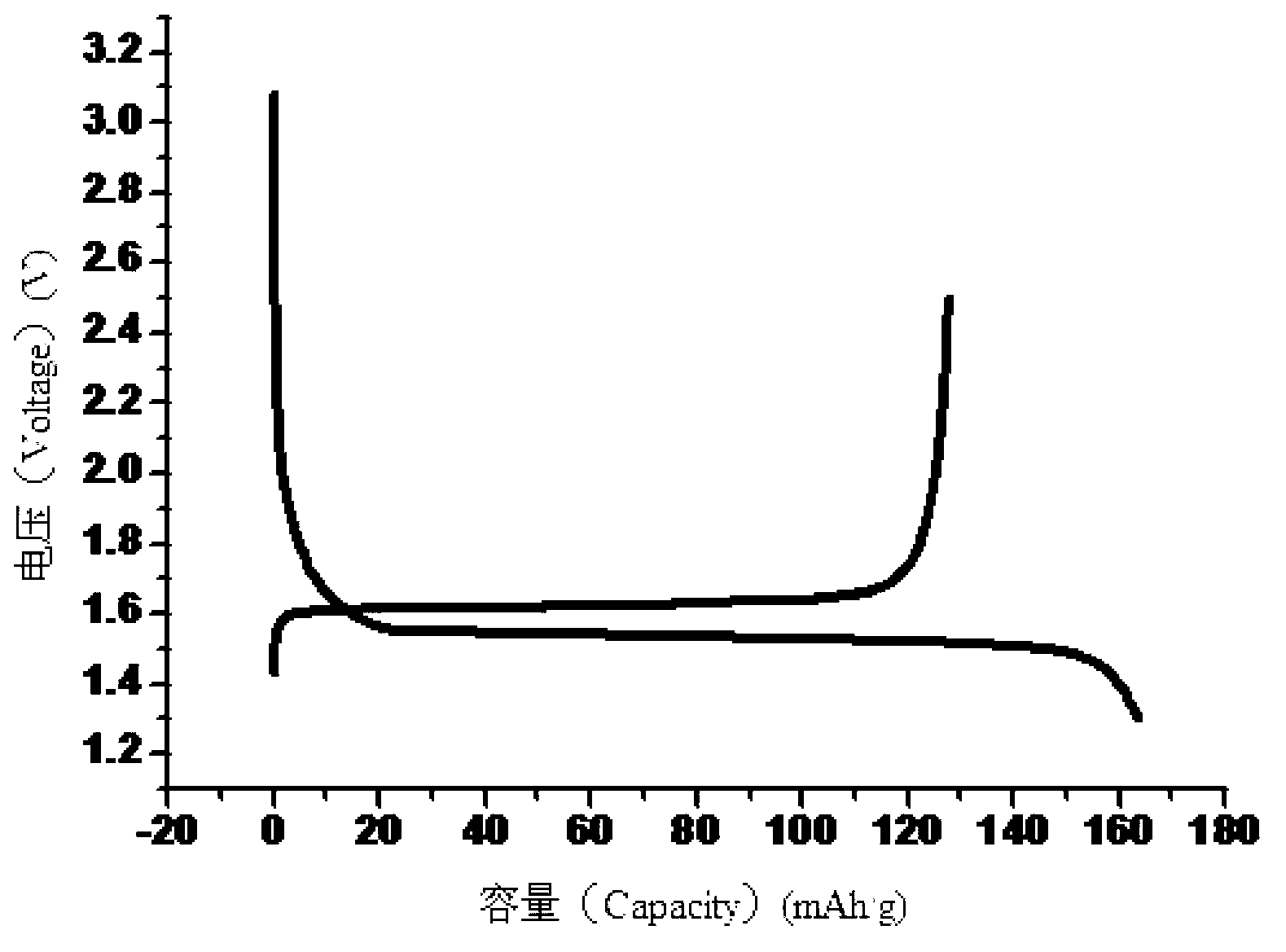

[0038] Repeat Example 1, the difference is that in the preparation of the electrolyte in step 1), the mass ratio of vinyl ethyl phosphate (EEP) to dimethyl methyl phosphate (DMMP) is 1:2. Figure 4 It is the first charge-discharge curve figure of 0.1C in the graphite / Li negative electrode half-cell of embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com