Method and device for making pizza

A production method and pizza technology, applied in the field of pizza production and its devices, can solve the problems of inflexible layout, poor flexibility, and long pizza time, and achieve manpower saving, strong practicability, and high production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of production method of pizza, comprises the steps:

[0044] 1. Metering of powder: the powder metering device 1 distributes the powder quantitatively;

[0045] Put the pre-mixed powder into the powder metering device 1. The powder is mainly composed of flour, and other ingredients such as wheat malt powder, baking powder, edible salt and other sugars are added as needed. The powder metering device 1 is a prior art, and will not be described in detail here. The powder metering device 1 distributes the powder required to produce a pizza from the powder metering device 1 to the powder stirring device 2 .

[0046] 2. Dough making: Quantitative powder and purified water are mixed and stirred in the powder stirring device 2 to form dough;

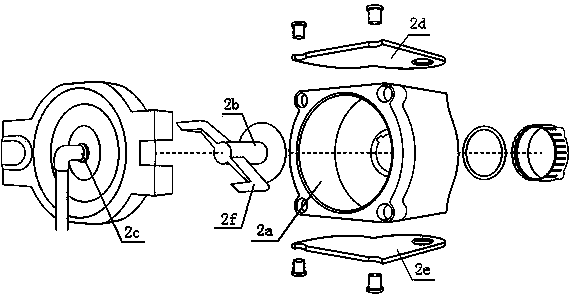

[0047] The cavity upper cover 2d of the powder stirring device 2 located below the powder metering device 1 is opened, and the distributed powder falls directly into the powder stirring device 2, and quantitative pure water enters...

Embodiment 2

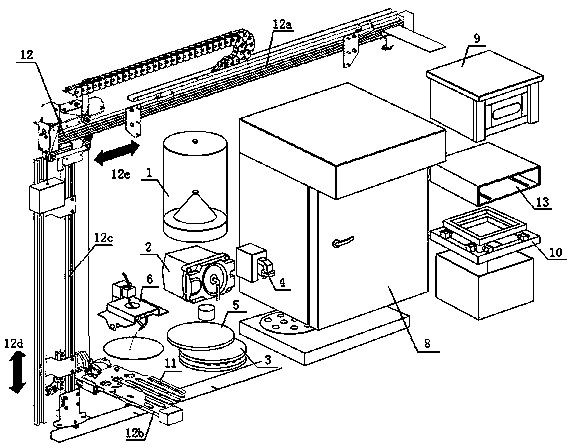

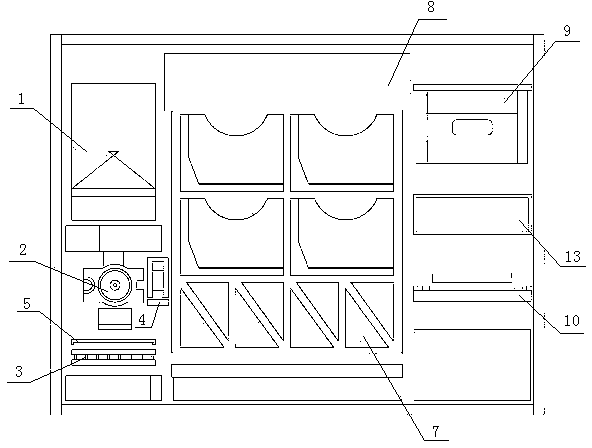

[0066] see figure 1 , figure 2 , as shown in the figure, which illustrates a device for producing pizza according to the present invention. The device includes a powder metering device 1, a powder stirring device 2, a pressurized heating chassis 3, a first pressurized heating device 4, a second pressurized heating device 5, an auxiliary material spreading device 6, and an ingredient laying device 7 , refrigerating device 8, oven 9, pizza box making device 10, conveying hand plate 11, conveying guide rail 12, pizza output window 13, control device, the above-mentioned parts are installed in a basic frame.

[0067] The control device includes a general industrial control box, which is used to control the operation of various components in the device for producing pizza. Specifically, the industrial control box sends operation instructions to each motor, and the components in the motor drive device operate.

[0068] The powder metering device 1 is used to measure the amount of...

Embodiment 3

[0082] In this embodiment, the automatic vending function is added to the device for producing pizza, and the rest are the same as in Embodiment 2.

[0083] There is a payment window and a user control panel on the shell of the device for producing pizza. The user pays through the payment window on the device. The payment method is coin or credit card. The user selects the taste of pizza through the control panel, and the control panel The optional pizza flavors in the unit are displayed on the top. After the fee payment is completed, the above-mentioned device is started to start the production of pizza. The production of a pizza starts from the powder metering device 1 and ends at the pizza output window 13 to the pizza with the packaging box. Concrete production process is identical with embodiment 1. It takes 2.5-3 minutes to make a pizza. The payment of the next user is completed, and the pizza production starts again. Wheels can also be arranged at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com