Royal jelly and preparation method thereof

A technology for royal jelly and honey, which is applied to the field of royal jelly and its preparation, can solve the problems of fresh liquid royal jelly being spicy, unacceptable to consumers, difficult to eat, etc., and achieves the effects of improving flavor and taste, soft taste and easy access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A water-in-oil type royal jelly microcapsule is obtained by the following preparation method:

[0059] (1) Take 4 parts by weight of honey, stir and melt in a 50°C water bath; then add 1 part by weight of inulin and 1 part by weight of resistant dextrin 1 to it in sequence, and stir while adding until the inulin and The resistant dextrin is completely dissolved, about 20 to 30 minutes, and cooled to room temperature to obtain an emulsifier;

[0060] (2) Take 1 part by weight of peanut oil, 1 part by weight of rapeseed oil and 3 parts by weight of milk cream with a fat content of 30-40% and mix them uniformly as the oil phase raw material in the emulsification system;

[0061] (3) Mix 20 parts by mass of fresh liquid royal jelly and the emulsifier prepared in step (1), and stir at 180-220rmp / min for 25-35min until uniform;

[0062] (4) Add the oil phase raw material prepared in step (2) to the mixture obtained in step (3), stir and mix at 180-220rmp / min, preferably for ...

Embodiment 2~5

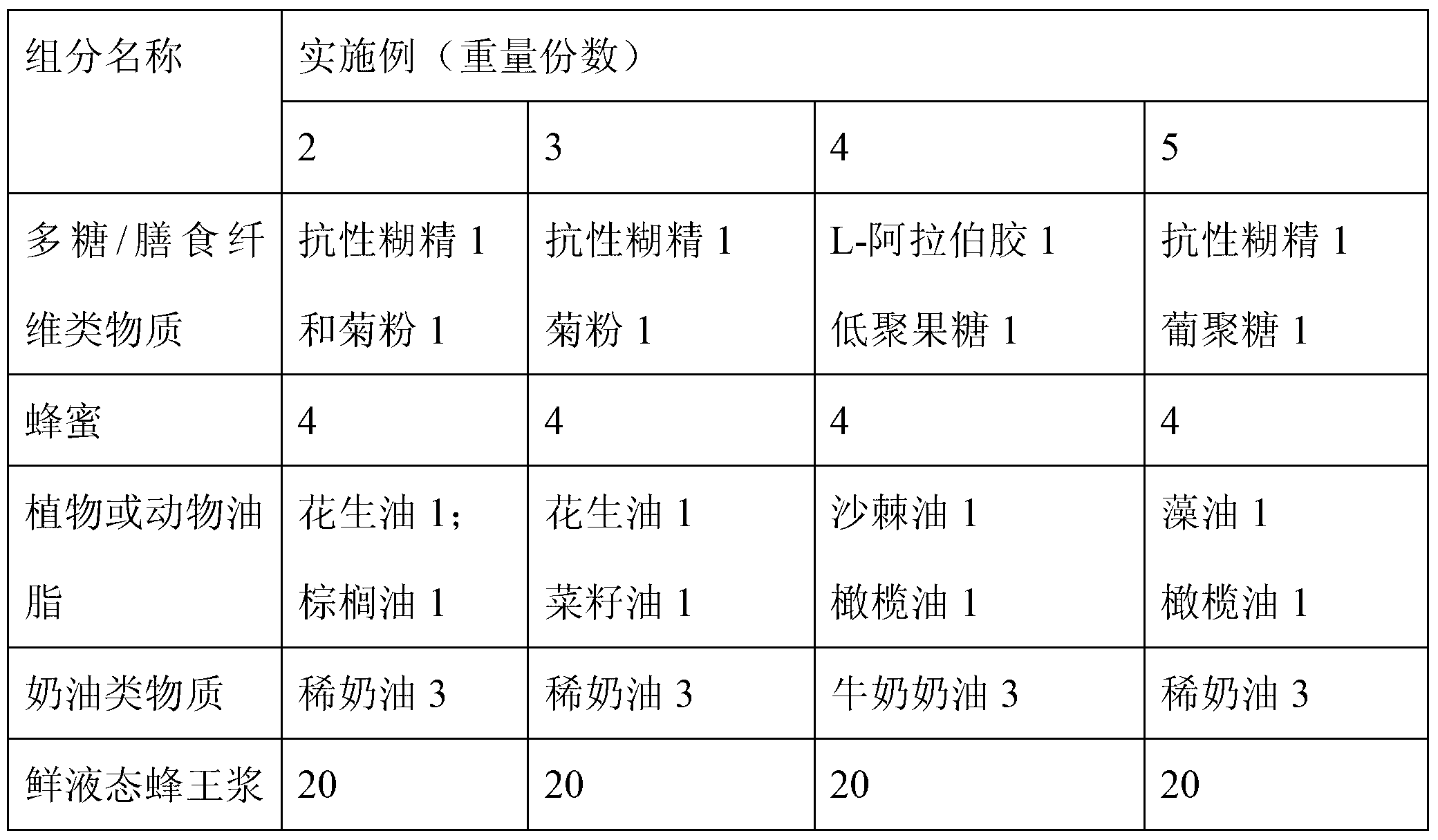

[0066] The method of embodiment 1 is repeated by each component specified in table 1 and the addition amount.

[0067] The raw material and the addition amount of the royal jelly microcapsule provided by Table 1 embodiment 2~5

[0068]

Embodiment 6~9

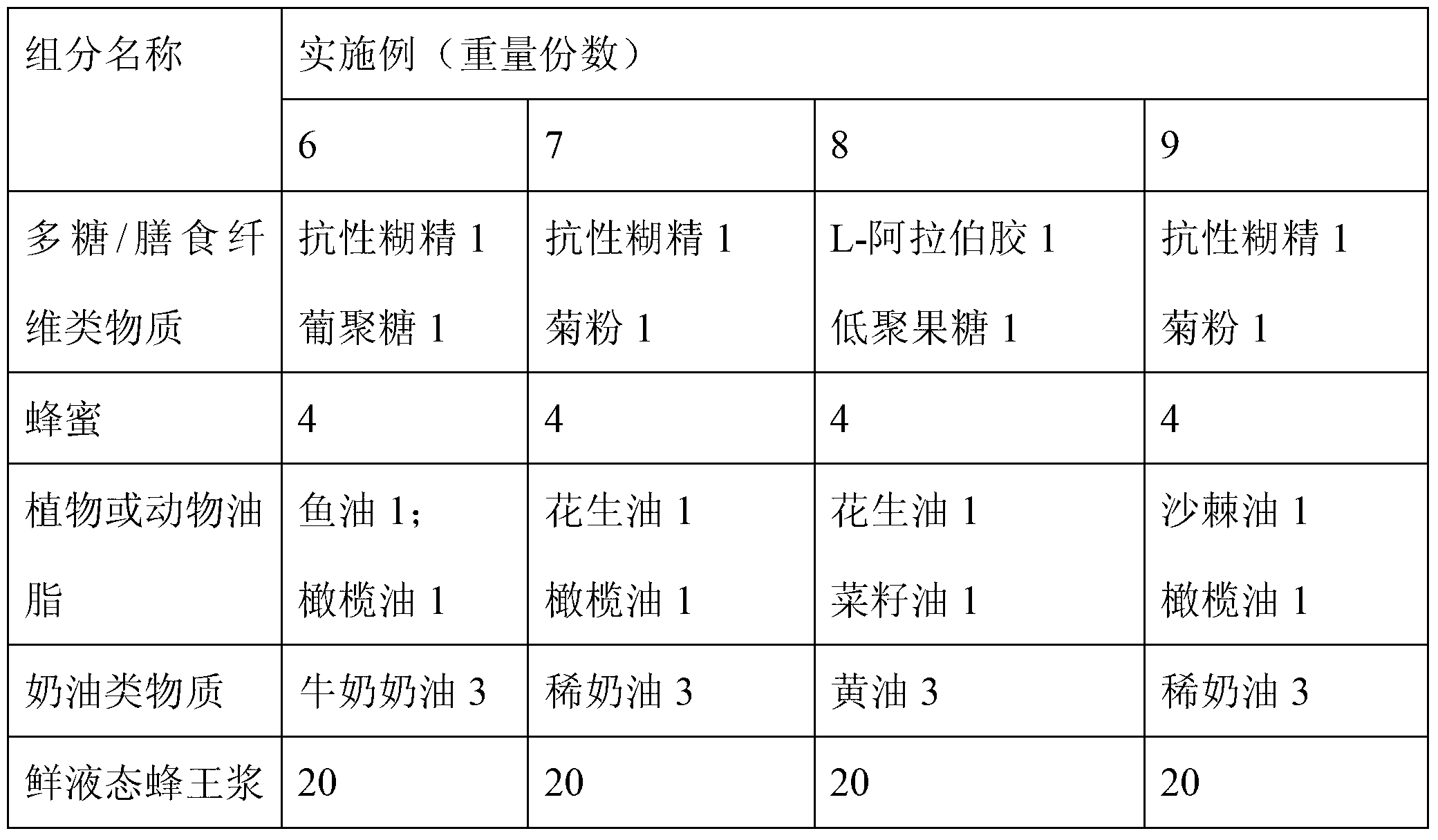

[0070] The method of embodiment 1 is repeated by each component specified in table 2 and the addition amount.

[0071] The raw material and addition amount of the royal jelly microcapsules provided by table 2 embodiment 6~9

[0072]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com