Special working clothes shell fabric

A technology for work clothes and fabrics, which is applied in clothing, clothing, special outerwear, etc., and can solve problems such as airtightness, bulky products, and poor texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

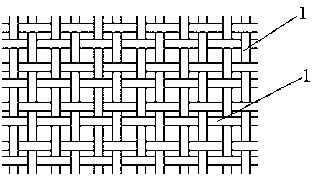

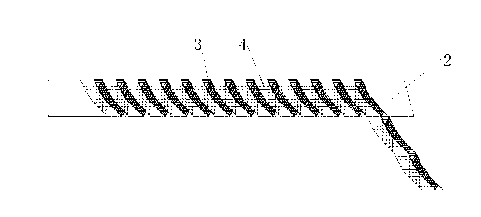

[0012] figure 1 and figure 2 A specific embodiment of a special workwear fabric with the structure of the present invention is shown: the special workwear fabric is woven by yarn 1, and yarn 1 is composed of glass fiber 2, polyvinyl chloride fiber 3 and polyimide fiber 4, chlorine fiber Alon fiber 3 and polyimide fiber 4 are spirally twisted with glass fiber 2 as the central axis, glass fiber 2 accounts for 45±2% of the mass of yarn 1, and polyimide fiber 4 accounts for yarn 1 The mass percentage of the main body is 20±2%, the mass percentage of the polyvinyl chloride fiber 2 in the main body of the yarn 1 is 35±2%, and the weaving density of the yarn 1 is 70S.

[0013] The beneficial effects of adopting the above technical scheme are: the special work clothes fabric with the structure of the invention has the characteristics of high temperature resistance, incombustibility, corrosion resistance, high tensile strength and good electrical insulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com