Wet releasing method for silicon-based MEMS device by using KOH solution

A solution and device technology, applied in the field of silicon-based MEMS device wet release, can solve the problems of cost increase, time saving and quality assurance, increase of CMP equipment, etc., to improve production efficiency, low production cost, and save process time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and by taking specific implementations as examples. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

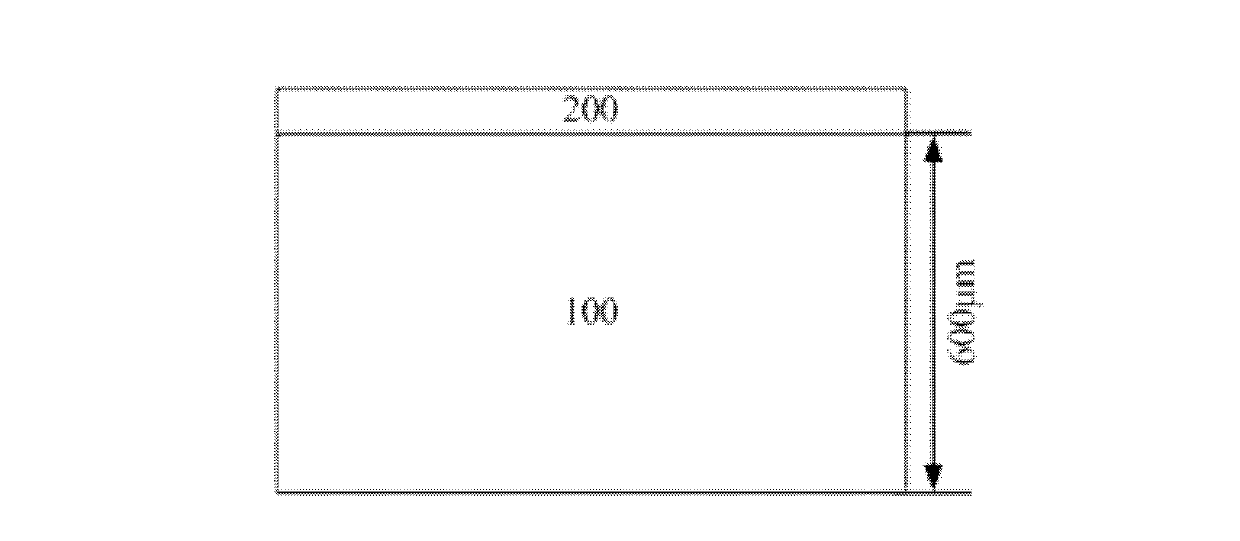

[0015] First prepare silicon-based MEMS devices, such as figure 1 As shown, the silicon-based MEMS device has a silicon substrate 100, the upper surface of the silicon substrate 100 has a circuit structure layer 200 that has been prepared, and the thickness of the silicon substrate 100 is 600 μm.

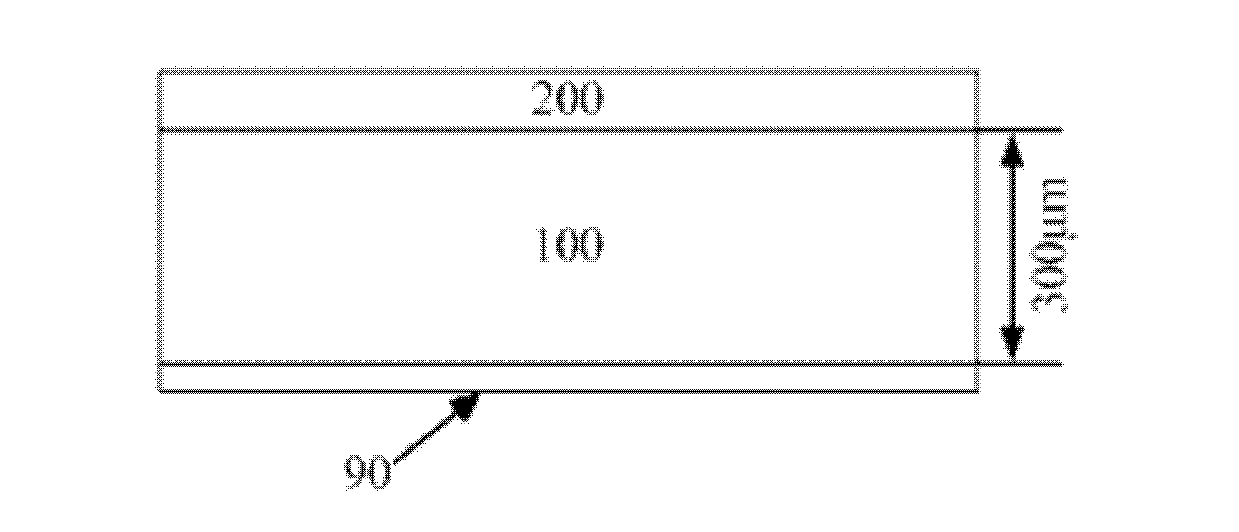

[0016] Step 100: Mechanically polishing the lower surface of the silicon substrate 100, such as figure 2 As shown in the embodiment, the silicon substrate 100 is thinned to 300 μm-450 μm; however, a mechanical damage layer 90 is formed on the lower surface of the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com