Energy-conservation and emission-reduction type active lime calcination method and apparatus

A technology of lime and high activity, applied in the direction of lime production, etc., can solve the problems of slowing heat transfer, low thermal efficiency, large resistance difference, etc., and achieve the effect of reducing heat energy loss and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

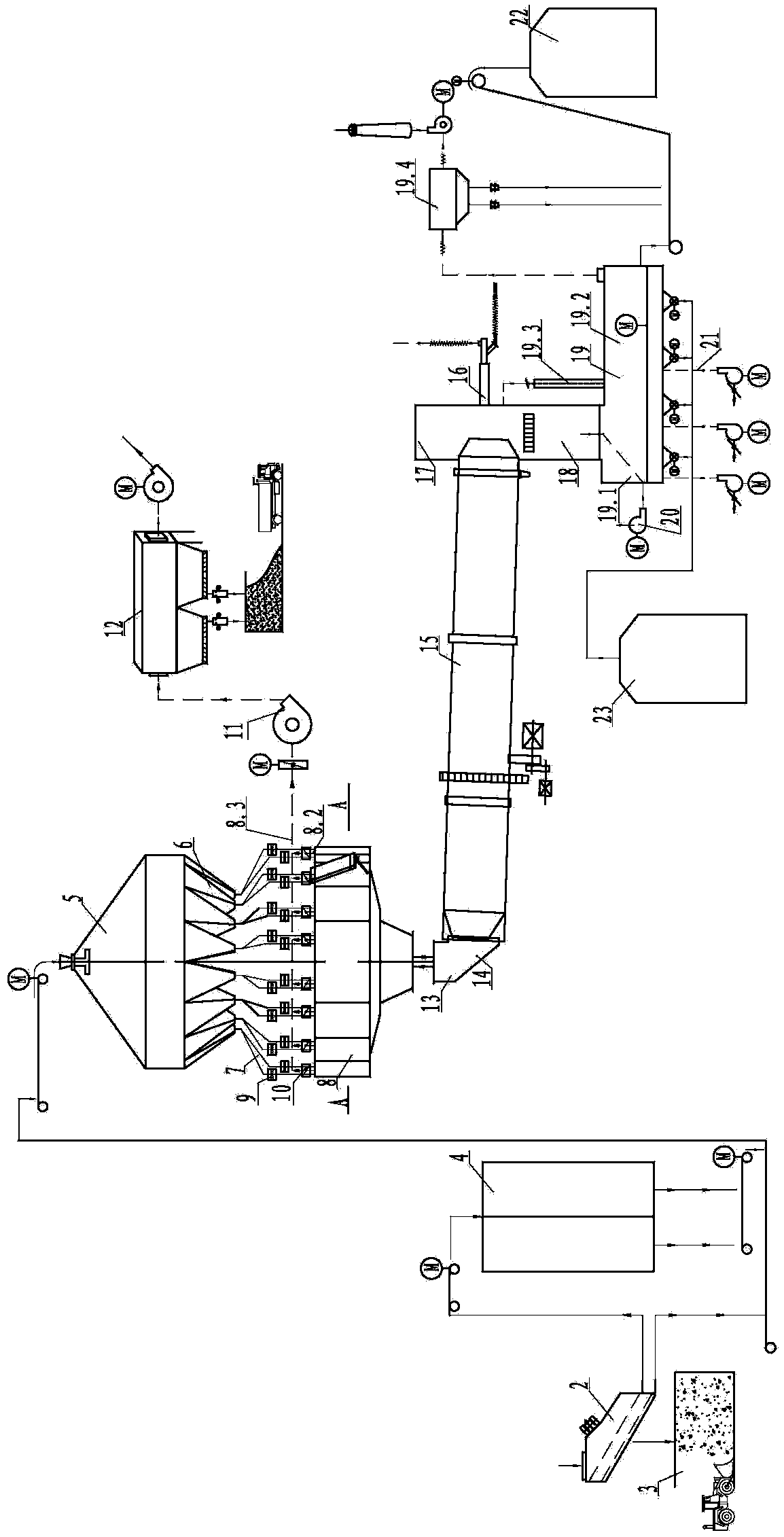

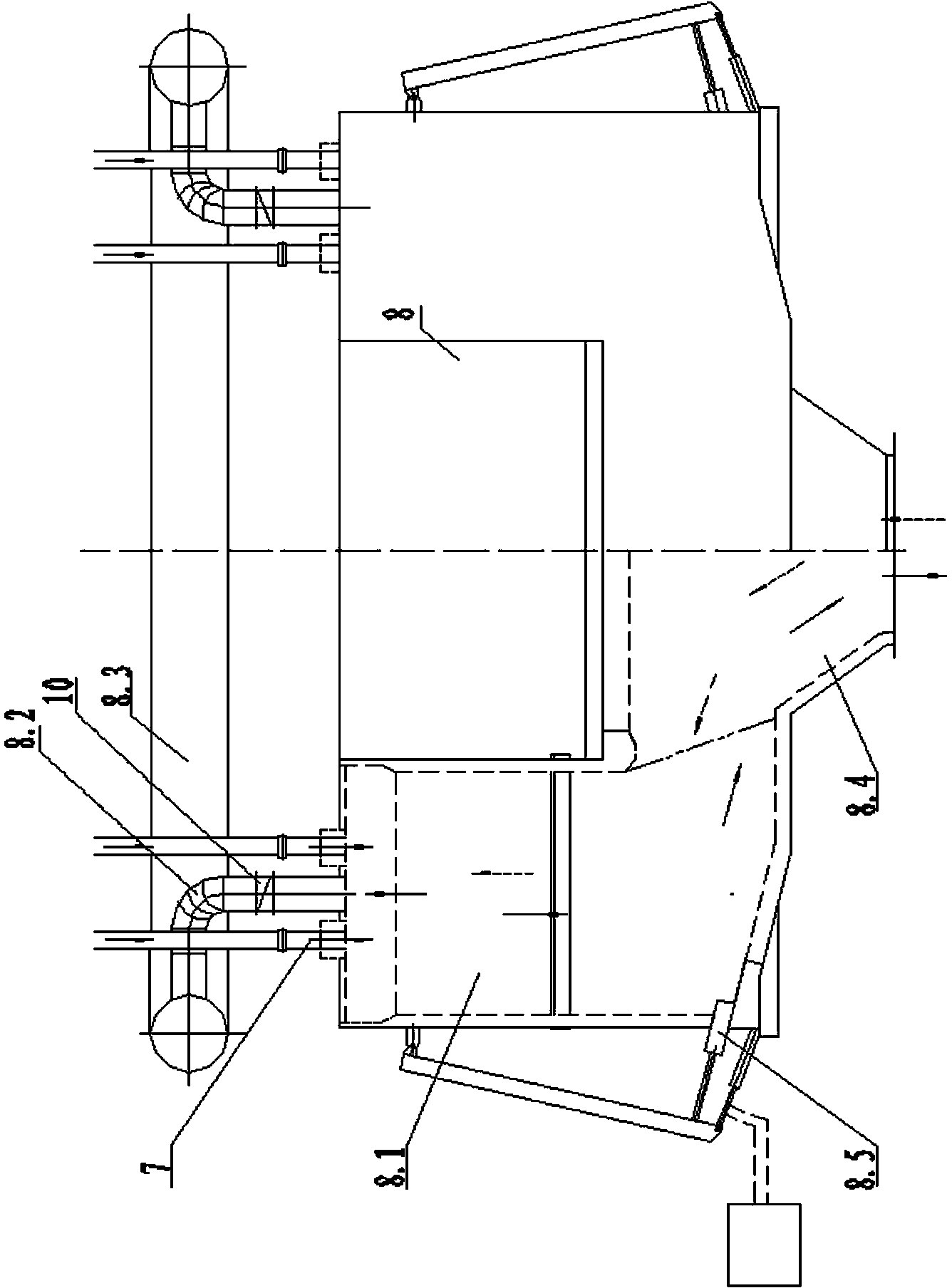

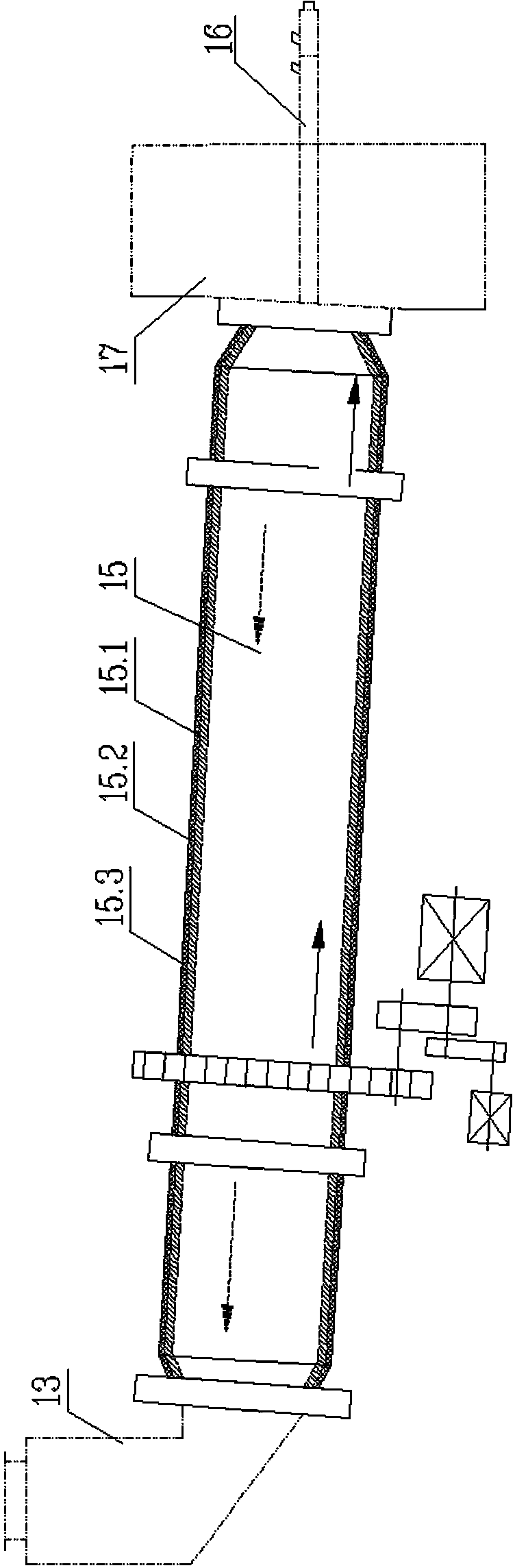

[0042] The invention provides a new preparation method for the production of active lime. Firstly, the raw limestone is subjected to particle size classification, and then the limestone of the same particle size is introduced into each preheating chamber of the vertical preheater, and the high-temperature waste gas is used to uniformly preheat it to It is above about 800°C and partially decomposed, and then introduced into the temperature field in the rotary kiln for calcination to decompose CO 2 , to become high-temperature lime, and then unload the high-temperature lime from the rotary kiln into the shaft device. After the shaft device is "simmered" and heat-exchanged to cool down, it enters the cooler for cooling, and then sieves to separate lump lime and powder lime. That is, the finished lump lime and powdered lime are obtained.

[0043] The present invention also provides a production device for implementing the preparation method, which includes a particle size classifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com