Method for preparing pleurotus cornucopiae cultivation material through cinnamomum longepaniculatum leaf residues

A technology of camphor leaf residue and cultivation materials, applied in the direction of application, fertilizer mixture, fertilization device, etc., can solve the problems of cost increase, waste of resources, pollution of the environment, etc., achieve the effect of reducing the cost of production raw materials and inhibiting the growth of mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

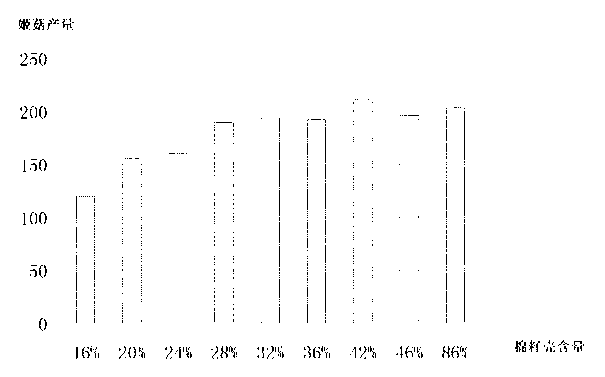

Image

Examples

Embodiment

[0012] Take 60 kg of waste camphor leaf residue (not moldy or rotten) that has been distilled and extracted from camphor oil, then add 1.8 kg of lime powder (sodium carbonate) and mix well, add 70L of water to infiltrate for 24 hours, adjust the pH value to 8.5, drain After dehydration, it is used as the main component of the cultivation material.

[0013] Then add 28 kg of cottonseed hulls, 10 kg of wheat bran, 1 kg of sugar, and 1 kg of gypsum powder, mix well, and at the same time add water slowly until the moisture in the compost is held by hand, and it is advisable that there are water droplets between the fingers but not dripping, pay attention to the mixing materials Mix evenly, absorb water evenly, and have a uniform pH.

[0014] Use lime powder to adjust the pH to 8.0.

[0015] Divide the mixed cultivation material into polypropylene bags with a thickness of 4 filaments, put them on the collar, and compact them slightly. Be careful not to let the small branches in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com