Method for preparing environment-friendly plasticizer cyclohexane dicarboxylic acid ester

A technology of cyclohexanedicarboxylate and environmentally friendly plasticizer, which is applied in the direction of carboxylate preparation, chemical instruments and methods, and the preparation of organic compounds, and can solve the problems of high reaction pressure, low conversion rate or selectivity, Solve the problems of high hydrogen consumption and achieve the effect of reducing hydrogen consumption, expanding the range of types, and reducing reaction energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

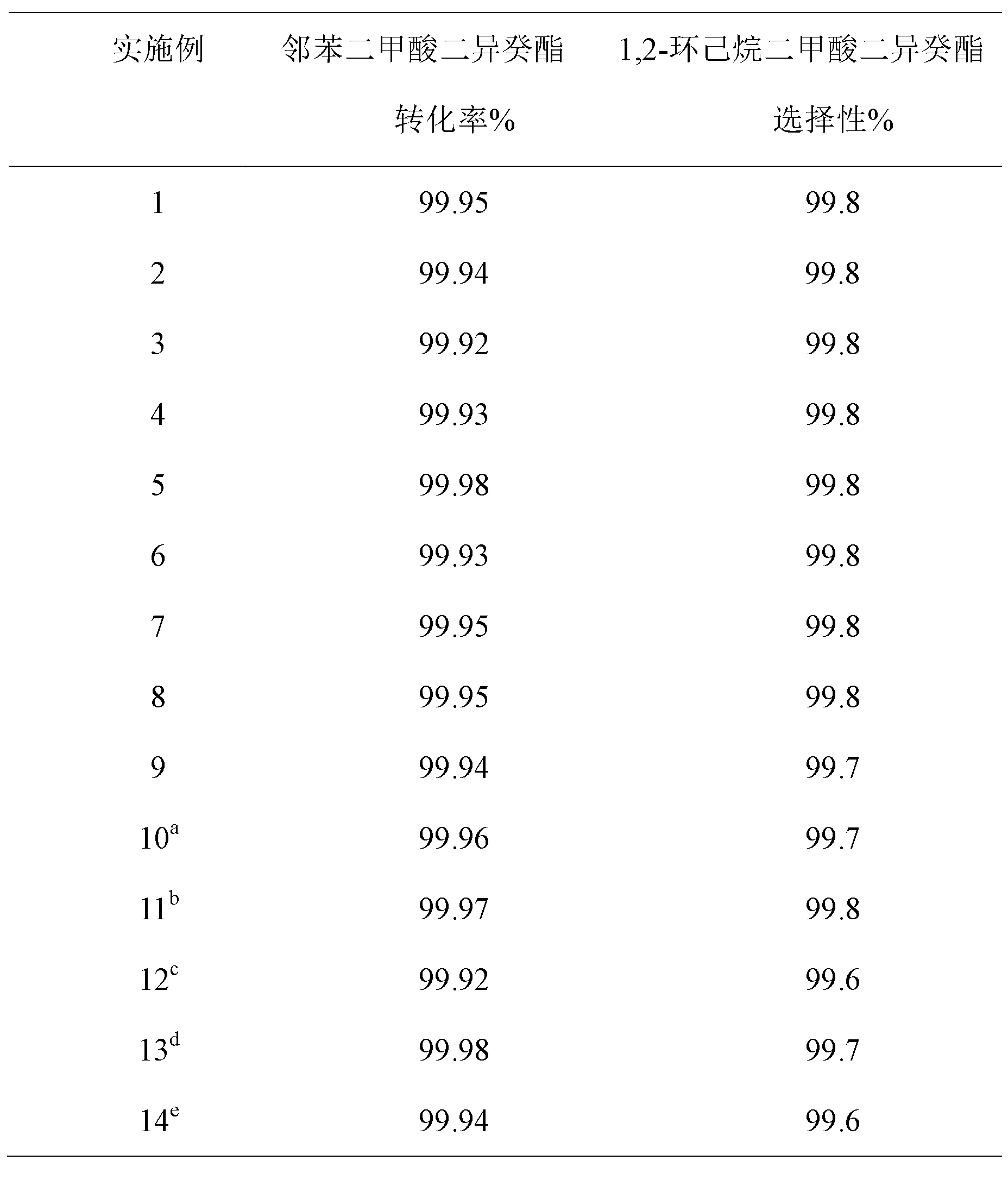

Examples

Embodiment 1

[0018] The catalyst used is Pd-Ru / SiO 2 -Al 2 o 3 . The weight composition of the catalyst is: Pd=0.1%, Ru=0.2%, and the rest is carrier SiO 2 -Al 2 o 3 . The catalyst active components Pd and Ru were supported on the carrier SiO by conventional impregnation method. 2 -Al 2 o 3 superior.

[0019] 10 grams of catalyst is activated by hydrogen before the reaction, the activation conditions are: GHSV=1000~2000h -1 , Atmospheric pressure ~1.0MPa, 200~300℃, reduction time 1~5 hours. Choose a fixed bed reactor.

[0020] The reaction temperature is 140°C, the hydrogen pressure is 15MPa, and the H 2 The / ester molar ratio is 15, and the volumetric space velocity of diisodecyl phthalate is 0.4h -1 , Reaction time 24h, sampling analysis.

[0021] The analysis of products and raw materials adopts gas chromatography, and the specific conditions are: nitrogen is the carrier gas, the flow rate is 1.5mL / min., and the injection volume is 4 microliters; FID hydrogen flame ion det...

Embodiment 2

[0023] The volume space velocity of diisodecyl phthalate is 0.3h -1 , other conditions are identical with embodiment 1.

Embodiment 3

[0025] The volume space velocity of diisodecyl phthalate is 0.5h -1 , other conditions are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com