Nano oxide wrapped mica iron oxide anti-rust pigment and preparation method thereof

A technology of micaceous iron oxide and nano-oxide, which is applied in chemical instruments and methods, anti-corrosion coatings, inorganic pigment treatment, etc., can solve the problems that zinc chrome yellow cannot be replaced, and achieve the effect of improving adhesion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

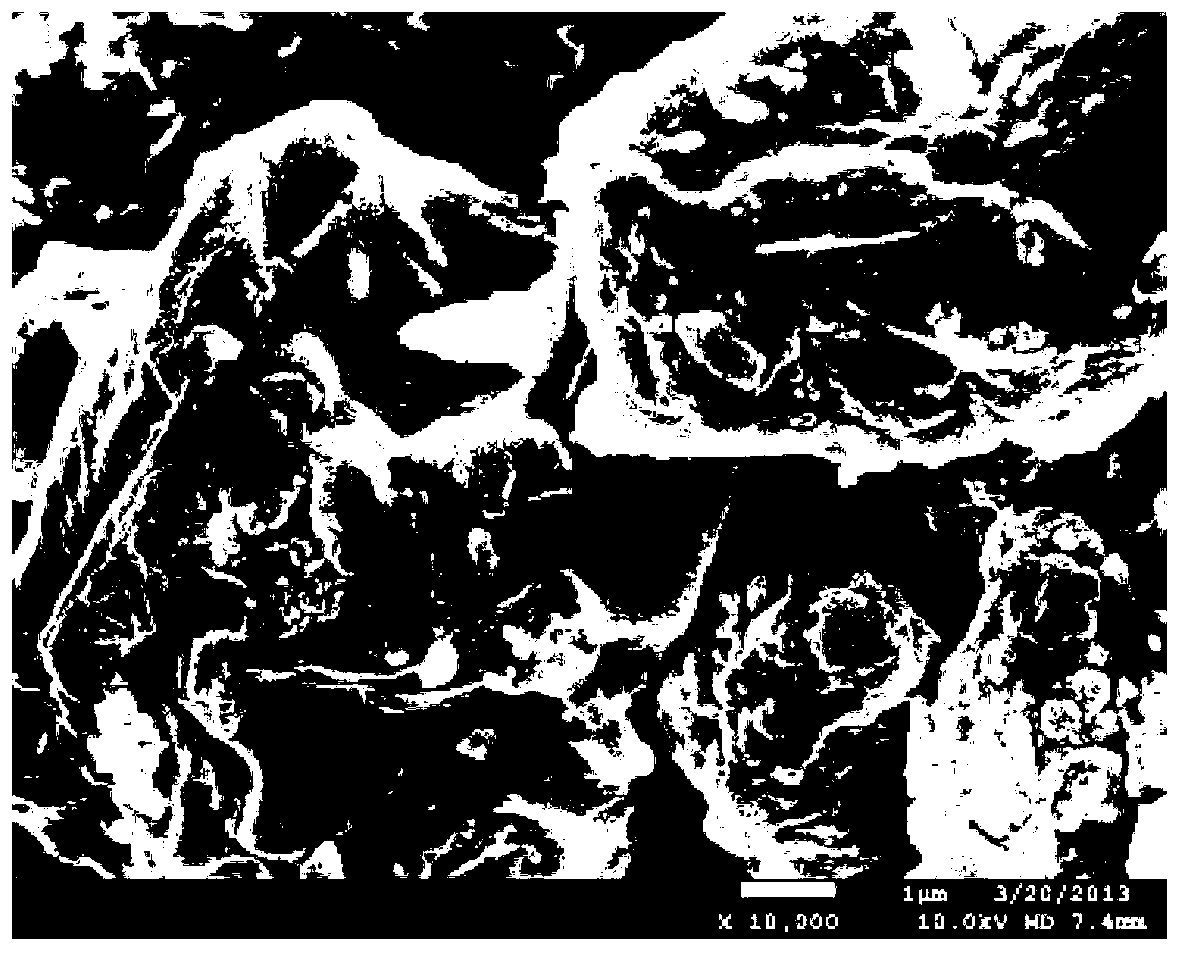

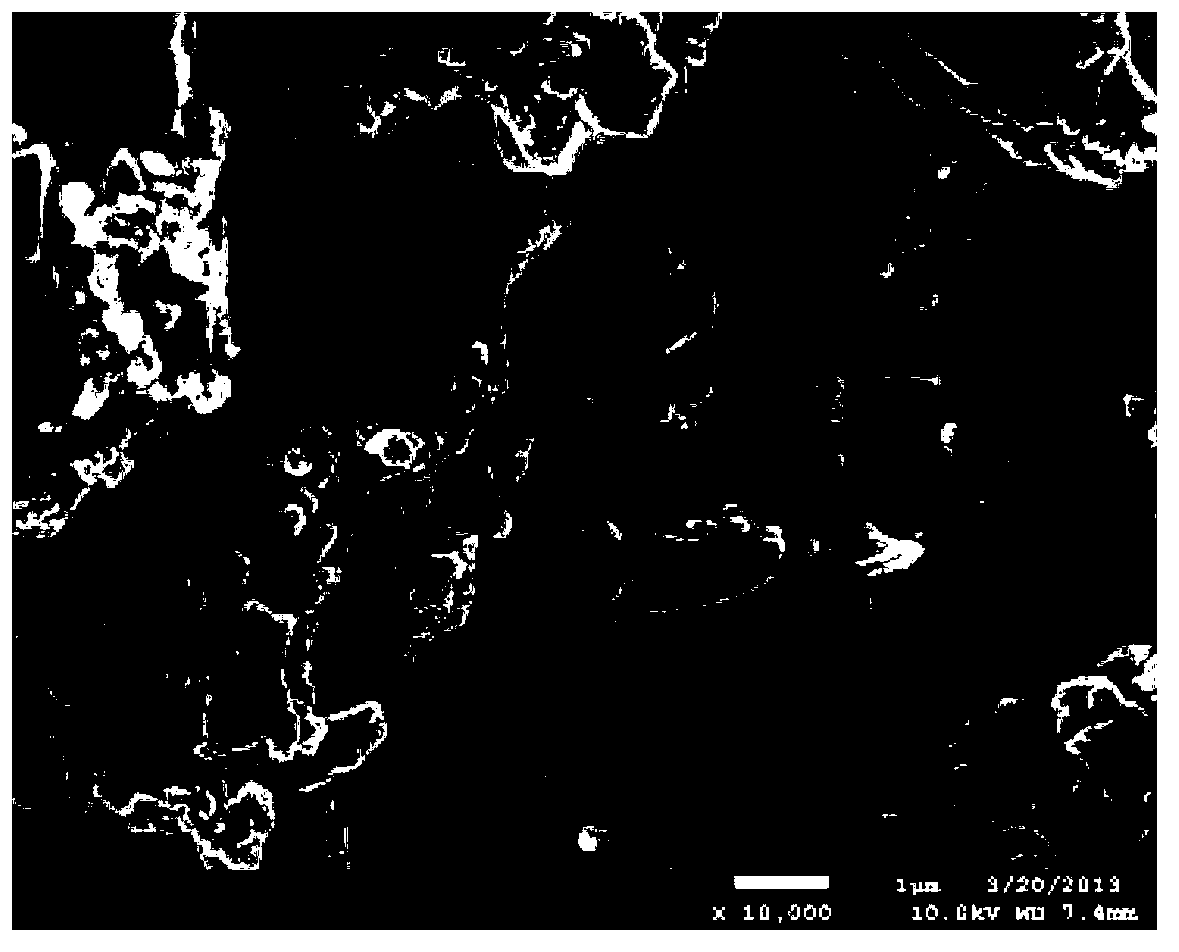

Image

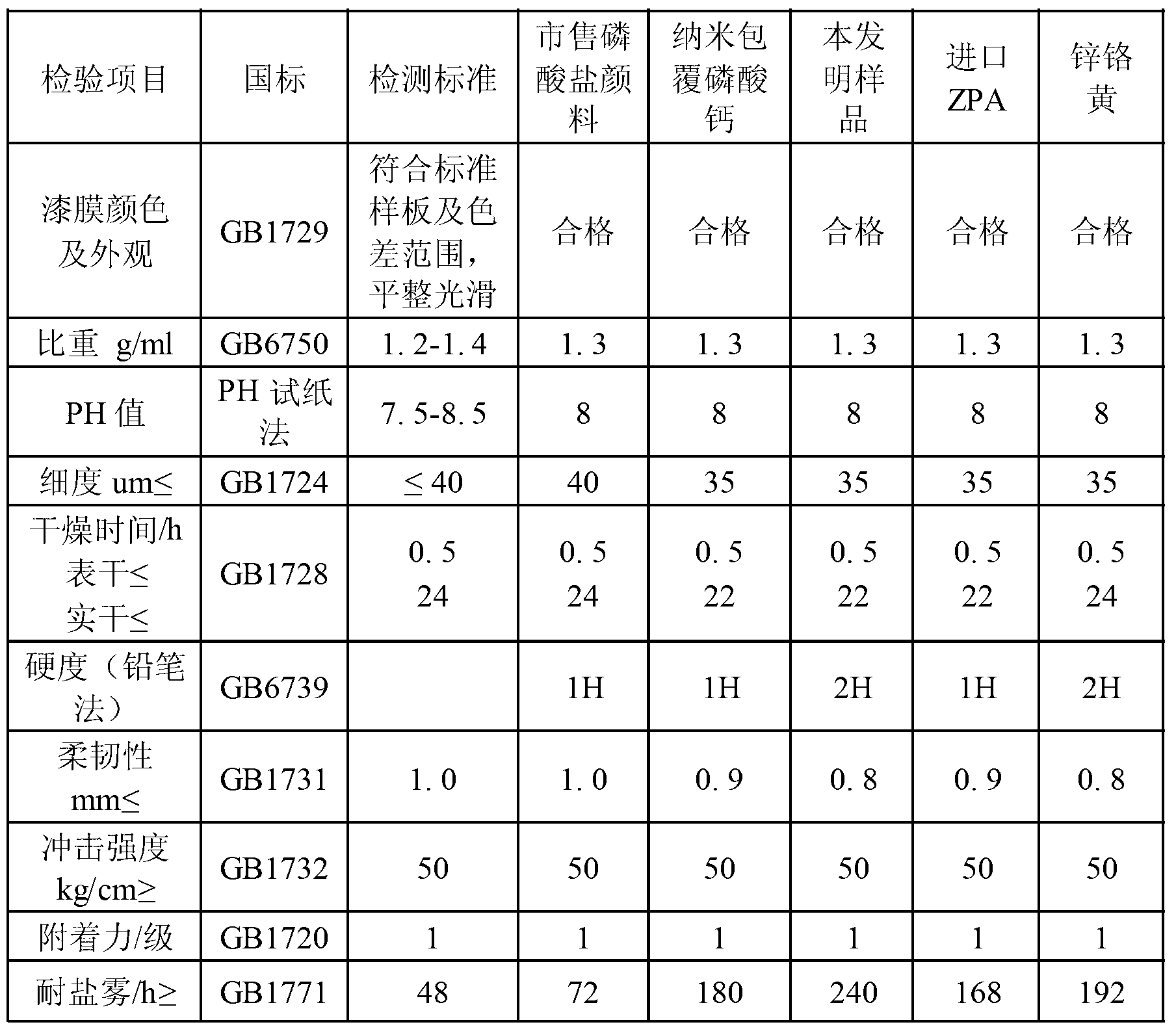

Examples

Embodiment 1

[0055] 1: Weigh 100g of 400 mesh mica iron oxide red, add 200g of water, and stir evenly;

[0056] 2: Dissolve 4.9g of titanyl sulfate in 50ml of water;

[0057] 3: Slowly drop the titanyl sulfate solution into the reactor containing mica iron oxide under stirring;

[0058] 4: Add 1.4g of calcium oxide after stirring continuously for 1 hour;

[0059] 5: Continue stirring for 30 minutes, filter, and dry at 100°C to obtain a red mica iron oxide antirust pigment coated with nano-titanium dioxide.

Embodiment 2

[0061] 1: Weigh 100g of 400 mesh mica iron oxide red, add 200ml of water and stir evenly;

[0062] 2: Dissolve 7g of zinc sulfate in 50ml of water;

[0063] 3: Slowly drop the zinc sulfate solution into the reactor containing micaceous iron oxide under stirring;

[0064] 4: Add 1.85g of calcium hydroxide after stirring continuously for 1 hour;

[0065] 5: Continue stirring for 30 minutes, filter, and dry at 100°C to obtain a red mica iron oxide antirust pigment coated with nano-zinc oxide.

Embodiment 3

[0067] 1: Weigh 100g of 400 mesh mica iron oxide ash, add 200ml of water and stir evenly;

[0068] 2: Dissolve 7g of zinc sulfate in 50ml of water;

[0069] 3: Slowly drop the zinc sulfate solution into the reactor containing micaceous iron oxide under stirring;

[0070] 4: Add 1.85g of calcium oxide after stirring continuously for 1 hour;

[0071] 5: Continue to stir for 30 minutes, filter, and dry at 100°C to obtain a gray micaceous iron oxide antirust pigment coated with nano-zinc oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com