Hot sticking glue for fire hose lining glue and preparation method thereof

A technology of fire hose and thermal bonding, which is applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of central nervous system damage, physical harm, eye irritation, etc., and achieve low price and coating Easy to brush and easy to prepare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

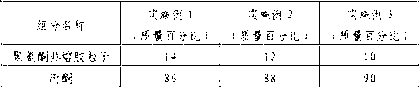

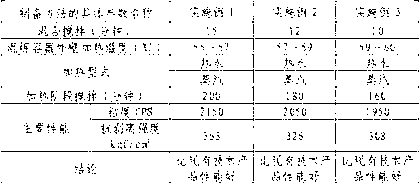

[0016] The hot glue used for the inner lining of fire hoses is a liquid glue, which contains the following components measured by mass percentage: 10% to 14% of polyurethane hot melt glue particles, and 86% to 90% of acetone. The preparation method of hot glue used for fire hose lining glue is carried out according to the following steps: first, quantitatively inject acetone into the mixing container, and evenly add the measured polyurethane hot melt glue particles into the acetone and mix and stir for 10 minutes ~15 minutes, then heat the outer wall of the mixing container to 55°C~60°C, control the temperature of the mixture of acetone and polyurethane hot melt adhesive particles in the mixing container at 37°C~40°C during the heating stage, and after 160 minutes~ Stir for 200 minutes to make hot glue. In the present invention, the heating temperature must be accurately controlled to ensure that the temperature of the acetone remaining in the mixing container cannot be lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com