Liquid crystal display (LCD) panel, alignment films thereof and preparation method of alignment films

A liquid crystal alignment and liquid crystal panel technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of small viewing angle, serious brightness difference and chromatic aberration, limitations, etc., to improve the mura situation, improve the optical quality, improve the The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

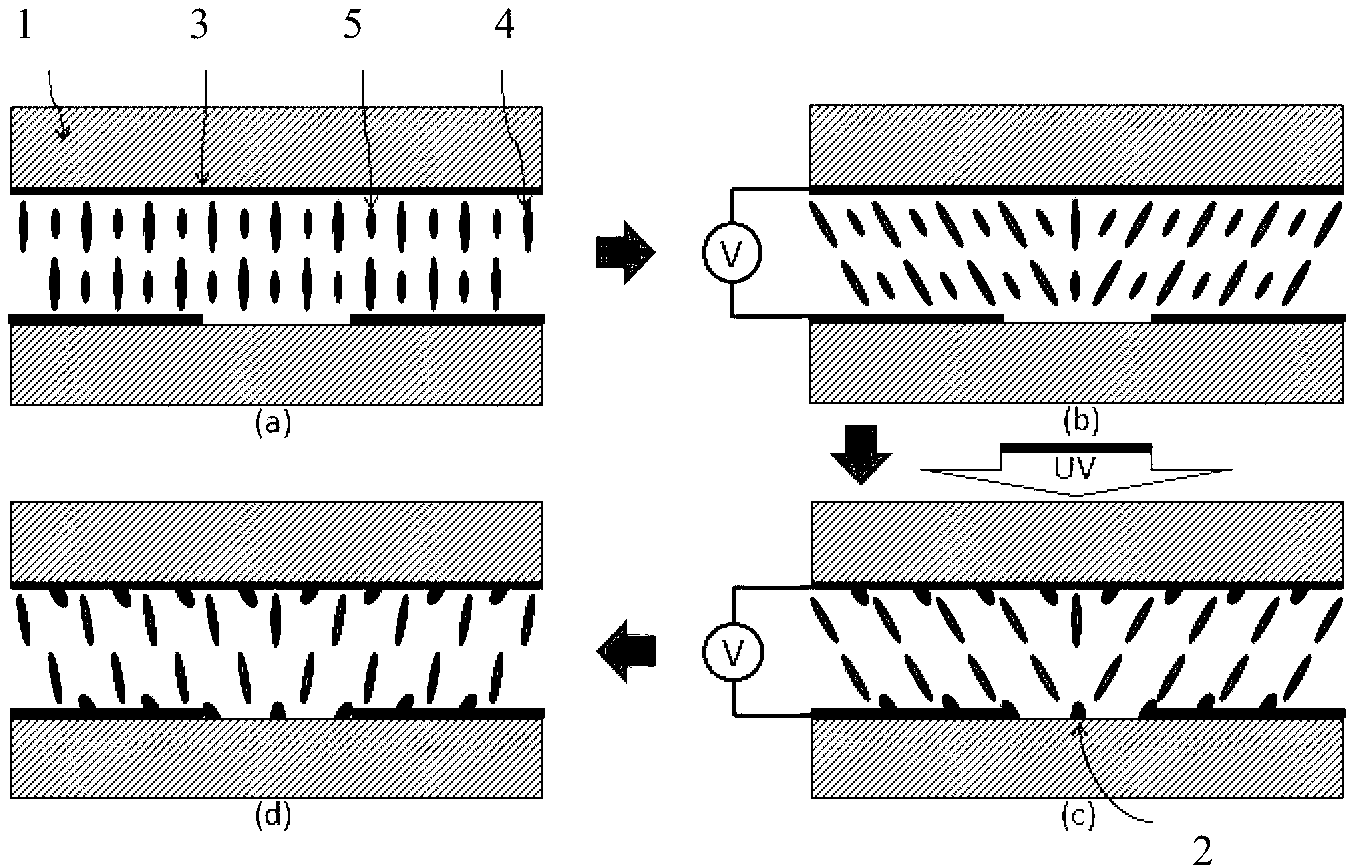

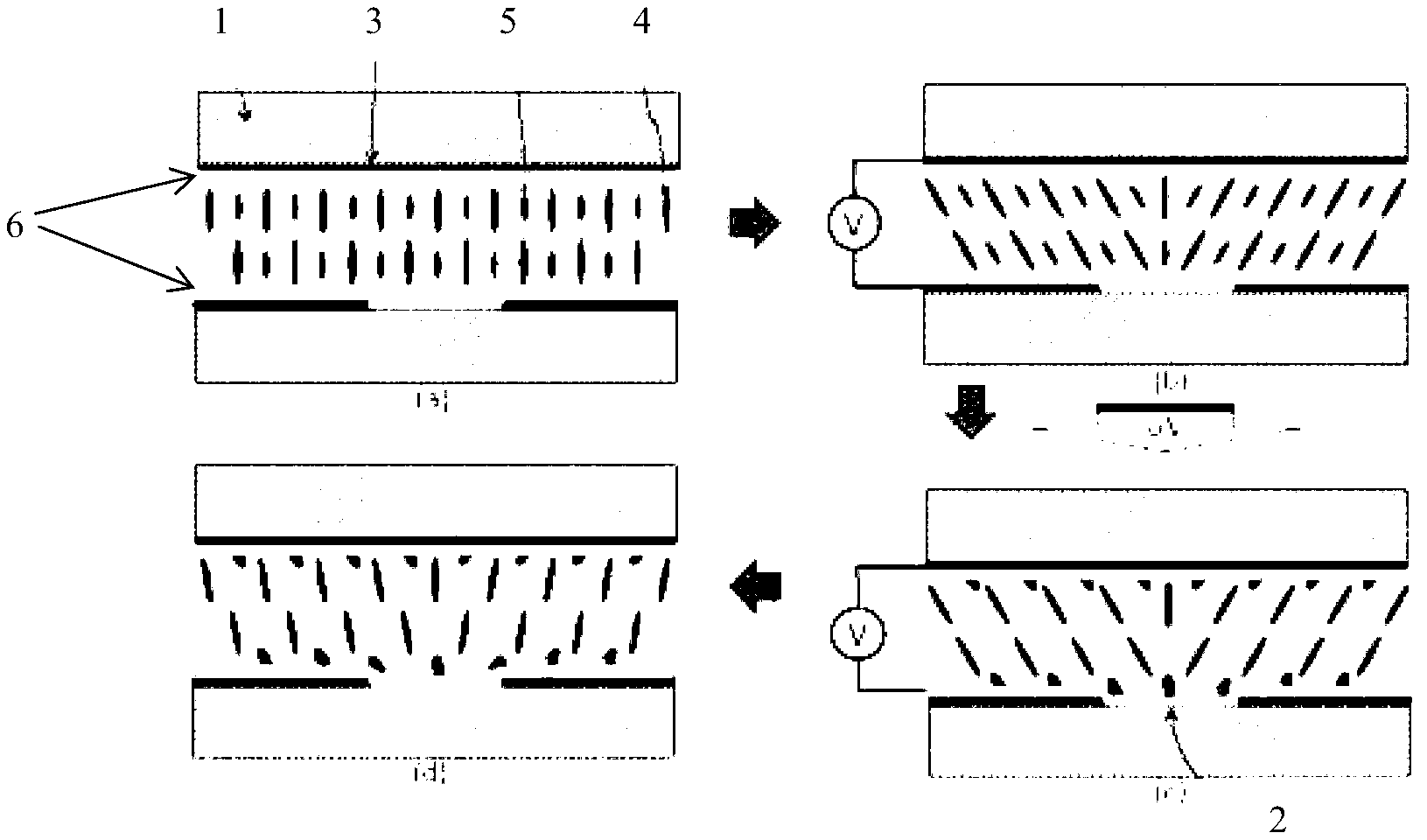

Method used

Image

Examples

Embodiment 1

[0038] This alignment molecule is formed by the polymerization of at least one monomer and has the following structural formula e:

[0039]

[0040] Wherein, the structural unit A and / or B has a terphenyl group.

[0041] This alignment molecule is usually a polyimide (PI) polymer formed by the dehydration polymerization of diamine monomers and dianhydride monomers. In this embodiment, a dianhydride monomer (see structural formula a1) with the following structure and two diamine monomers (see structural formula t1 and b1) are used for polymerization. The ratio of the amount of monomers represented by structural formula a1, t1, and b1 is 5:2:3, and the polyimide alignment type molecule PI-1 is synthesized.

[0042] Structural formula a1

[0043] Structural formula t1

[0044] Structural formula b1

[0045] In this embodiment, the proportion of terphenyl-containing monomer t1 accounts for 20% of the total amount of all monomers. Since the monomer of structural formula t1 c...

Embodiment 2

[0057] Compared with Example 1, this embodiment is different in that the alignment molecule is formed by the monomers of structural formula a1, structural formula t2, and structural formula b1 to form polyimide alignment molecule PI-2.

[0058] Structural formula a1

[0059] Structural formula t2

[0060] Structural formula b1

[0061] In this example, the ratio of the amount of monomers represented by structural formulas a1, t2, and b1 is 5:1:4, and the amount of terphenyl is 10% of the total monomers, forming a polymer The molecular weight of PI-2 is 5000~5×10 5 between. Similarly, structural formula t2 contains a terphenyl structure, and the formed alignment molecule PI-2 must contain a terphenyl structure.

[0062] The oriented molecule PI-2 is dissolved in a mixed solvent of NMP and γ-butyrolactone (γ-BL), and then the leveling agent isophorone is added and mixed uniformly. Wherein NMP accounts for 95% of the mass percentage of the alignment film solution, γ-BL ac...

Embodiment 3

[0068] Compared with Example 1, this embodiment is different in that the alignment molecule is a polyimide alignment molecule PI-3 formed from monomers of structural formula a2, t2 and structural formula b2.

[0069] In this embodiment, the monomers of structural formula a2, t2, and b2 are in a ratio of 5:1.5:3.5 according to the amount of substances, and the amount of terphenyl group is 15% of the total amount of monomers, forming an alignment molecule The molecular weight range of PI-3 is 5000~1×10 5 . Similarly, structural formula t2 contains a terphenyl structure, and the formed alignment molecule PI-2 must contain a terphenyl structure.

[0070] Structural formula a2

[0071] Structural formula t2

[0072] Structural formula b2

[0073] Dissolve the material of PI-3 in the mixed solvent of NMP and N-ethylpyrrolidone (NEP), then add the leveling agent diacetone alcohol and mix well. The mass percentage of NMP in the alignment film solution is 85%, the mass percenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com