A composite rotor structure bearingless switched reluctance motor

A technology of switched reluctance motor and composite rotor, which is applied to the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc. High-speed performance of the motor, winding current tracking chopper control, etc., to achieve the effect of high slot full rate, simple structure, and small interphase coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail;

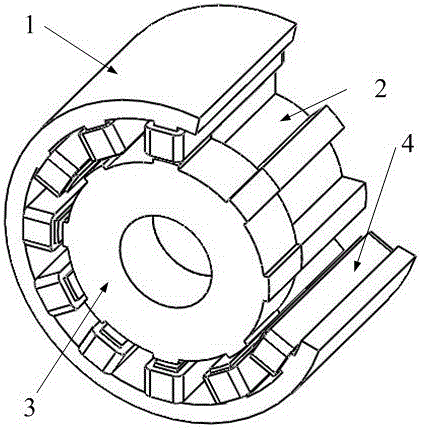

[0019] like figure 1 Shown: a bearingless switched reluctance motor with a compound rotor structure, including a stator 1, a torque rotor 2, a levitation force rotor 3, and a winding 4; a set of windings 4 are wound on the stator teeth of the stator 1; Composed of the levitation force rotor 3, the torque rotor 2 and the levitation force rotor 3 are axially superimposed and arranged in the stator 1; the torque rotor 2 is used to generate torque, and the levitation force rotor 3 is used to generate levitation force and partial torque.

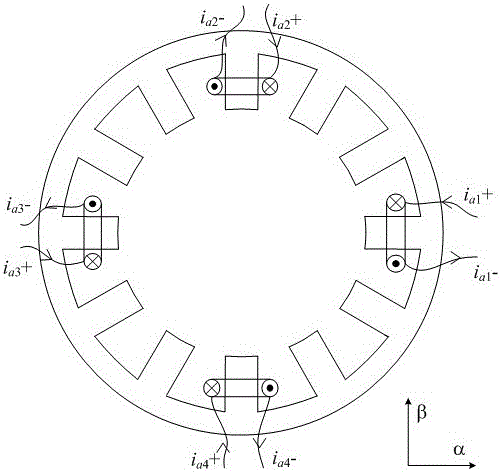

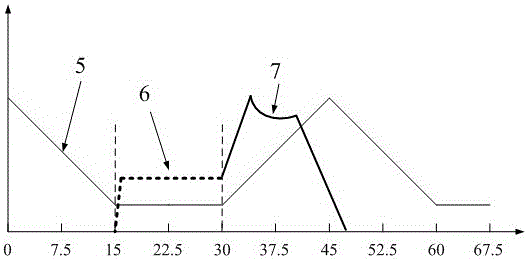

[0020] The stator is a salient pole structure with 12 teeth. Both the torque rotor 2 and the levitation force rotor 3 have 8 rotor teeth; the winding 4 is in the form of a concentrated winding, and each phase winding is composed of four windings on the stator separated by 90°, and the four windings of each phase are independently contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com