Regeneration process method and device for solid adsorbent

A solid adsorbent and regeneration device technology, applied in separation methods, filter regeneration, petroleum industry, etc., can solve the problems of large gas or fuel energy consumption, complex equipment, and flue gas pollution, and reduce energy consumption and cost. Inexpensive, Emission Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The regeneration process of the solid adsorbent in this embodiment includes the following steps: (S1) generating a thermal plasma with a gas temperature above 120°C; (S2) directly or indirectly using the heat of the thermal plasma and / or the activity of the active species The effect is to desorb the adsorbate loaded on the solid adsorbent; (S3) the adsorbate desorbed from the solid adsorbent circulates into the thermal plasma, and under the action of the thermal plasma, the adsorbate is oxidized, decomposed or reduced, and carbonized; ( S4) Adsorbate conversion products are directly discharged or collected.

[0041] In the above embodiments, the adsorbate desorbed from the solid adsorbent circulates into the plasma, and then under the action of the plasma and the addition of auxiliary reaction gas according to the type of the adsorbate, the adsorbate is oxidized, decomposed, reduced or carbonized to convert It is a harmless product, and the carbonized product produced b...

Embodiment 2

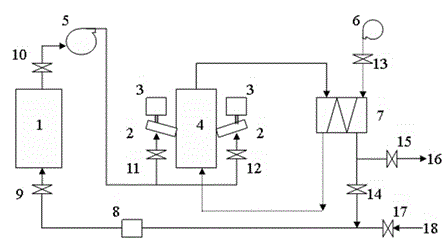

[0050] Such as figure 1 Shown is a structural diagram of a specific embodiment of a solid adsorbent regeneration device in the present invention. see figure 1 , the solid adsorbent regeneration device of this embodiment includes a solid adsorbent device 1, a plasma generator, a fan 5 and an exhaust port 16;

[0051] Wherein, the solid adsorbent device 1 is loaded with a solid adsorbent;

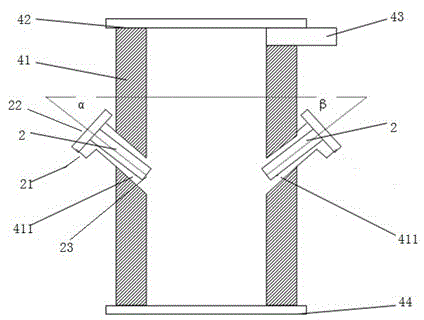

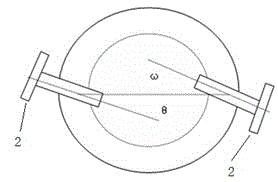

[0052] This plasma generator comprises plasma torch 2, plasma power supply 3 and plasma furnace 4, and plasma power supply 3 is connected with plasma torch 2, and plasma torch 2 is connected with plasma furnace 4, and solid adsorbent equipment 1 is connected with plasma torch 2 through pipeline, and plasma The furnace 4 is connected to the solid adsorbent equipment 1 through pipelines, and a circulation loop is formed between the solid adsorbent equipment 1, the plasma torch 2, and the plasma furnace 4;

[0053] Fan 5 is connected in the circulation circuit, and its connection position can...

Embodiment 3

[0068] Such as Figure 4 As shown, the difference from Embodiment 2 is that the exhaust port 16 of this embodiment is connected to the heat exchanger 7 through a pipeline, and then connected to the circulation pipeline through the heat exchanger 7 . In addition, the heat exchanger 7 is also connected with an air inlet 19 through which air is input, and then the adsorbent in the solid adsorbent device 1 is heated after heat exchange by the heat exchanger 7 . when working, such as Figure 4 As shown, the plasma torch 2 is ignited, the fan 5 is operated, and the air enters the heat exchanger 7 from the air inlet 19 for preheating and enters the solid adsorbent device 1 through the air valve 9, and the adsorbent in the solid adsorbent device 1 is heated. After the air is heated, the adsorbate loaded on it is desorbed; the airflow carrying the adsorbate passes through the air valve 10, the fan 5, the air valves 11 and 12, and the plasma torch 2 and enters the plasma furnace 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com