Photocatalyst Cd/CdS containing catalyst promoter Cd as well as preparation method and application of photocatalyst Cd/CdS in photocatalysis hydrogen production reaction

A photocatalyst and co-catalyst technology, applied in the field of photocatalysis, can solve the problems of CdS prone to photolytic corrosion, limitation, etc., and achieve the effect of improving the photocatalytic hydrogen production efficiency, low cost, stable structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

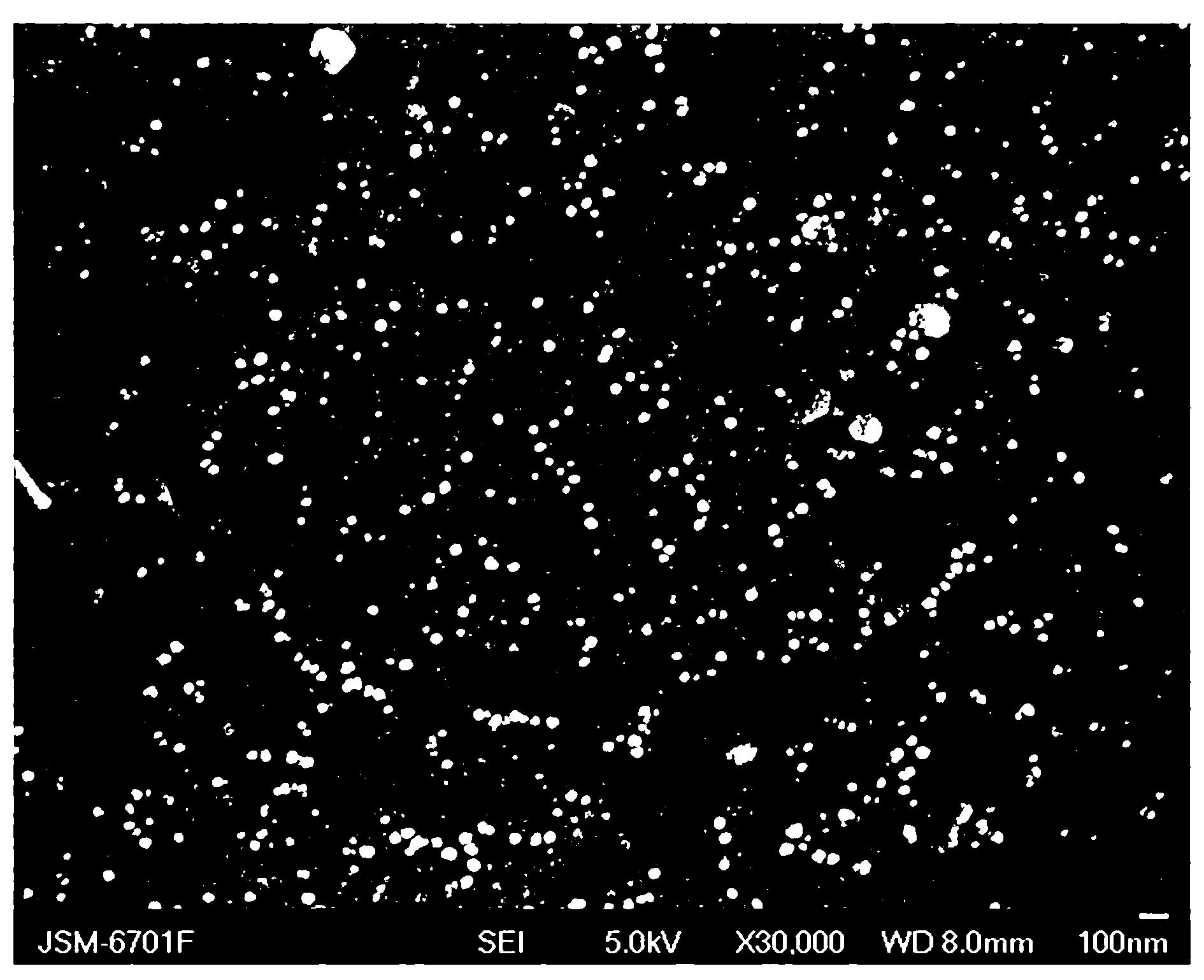

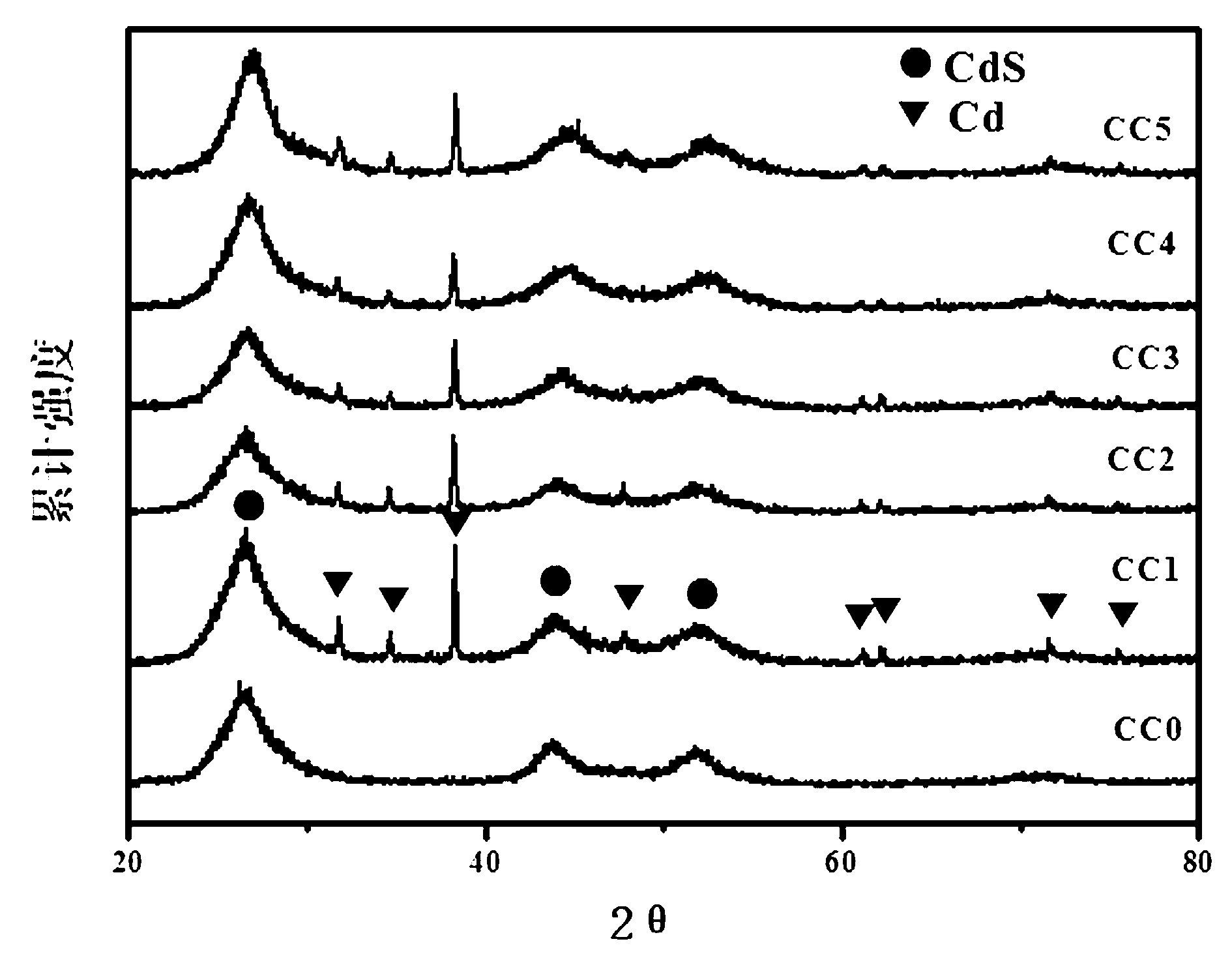

[0035] 1. Preparation of photocatalyst Cd / CdS

[0036] (1) 4.617 g of 3CdSO 4 ·8H 2 O was dissolved in 40 mL of distilled water to form a 0.15 M solution;

[0037] (2) 7.445 gNa 2 S 2 o 3 ·5H 2 O was dissolved in 40 mL of distilled water to make a concentration of 0.75 M Na 2 S 2 o 3 ·5H 2 O solution;

[0038] (3) 3CdSO 4 ·8H 2 O solution and Na 2 S 2 o 3 ·5H 2 O solution was mixed, stirred for 20 min, and then ultrasonically treated for 45 min at an ultrasonic power of 50 Hz;

[0039] (4) The mixed solution was reacted under a 350W xenon lamp for 25 hours, and then heated in a 500W microwave oven for 15 minutes;

[0040] (5) The reaction solution was centrifuged at 8000 rpm to obtain a precipitate, washed 10 times with double distilled water, then washed 2 times with ethanol, dried at 80°C for 12 h, and ground to obtain a catalyst sample containing co-catalyst Cd, record for CC1. Wherein the mass percentage of Cd is 5%.

[0041] 2. Performance test

[0042]...

Embodiment 2

[0044] 1. Preparation of photocatalyst Cd / CdS

[0045] (1) 4.617 g of 3CdSO 4 ·8H 2 O was dissolved in 40 mL of distilled water to form a 0.15 M solution;

[0046] (2) 8.935 gNa 2 S 2 o 3 ·5H 2 O was dissolved in 40 mL of distilled water to make a concentration of 0.9 M Na 2 S 2 o 3 ·5H 2 O solution;

[0047] (3) 3CdSO 4 ·8H 2 O solution and Na 2 S 2 o 3 ·5H 2 The O solution was mixed, stirred for 20 min, and then ultrasonically treated for 15 min at an ultrasonic power of 100 Hz;

[0048] (4) The mixed solution was reacted under a 350W xenon lamp for 15 hours, and then heated in a 750W microwave oven for 5 minutes;

[0049] (5) The reaction solution was centrifuged at 8000 rpm to obtain a precipitate, washed 10 times with double distilled water, then washed 2 times with ethanol, dried at 80°C for 12 h, and ground to obtain a catalyst sample containing co-catalyst Cd, record for CC2. Wherein the mass percentage of Cd is 12%.

[0050] 2. Performance test

...

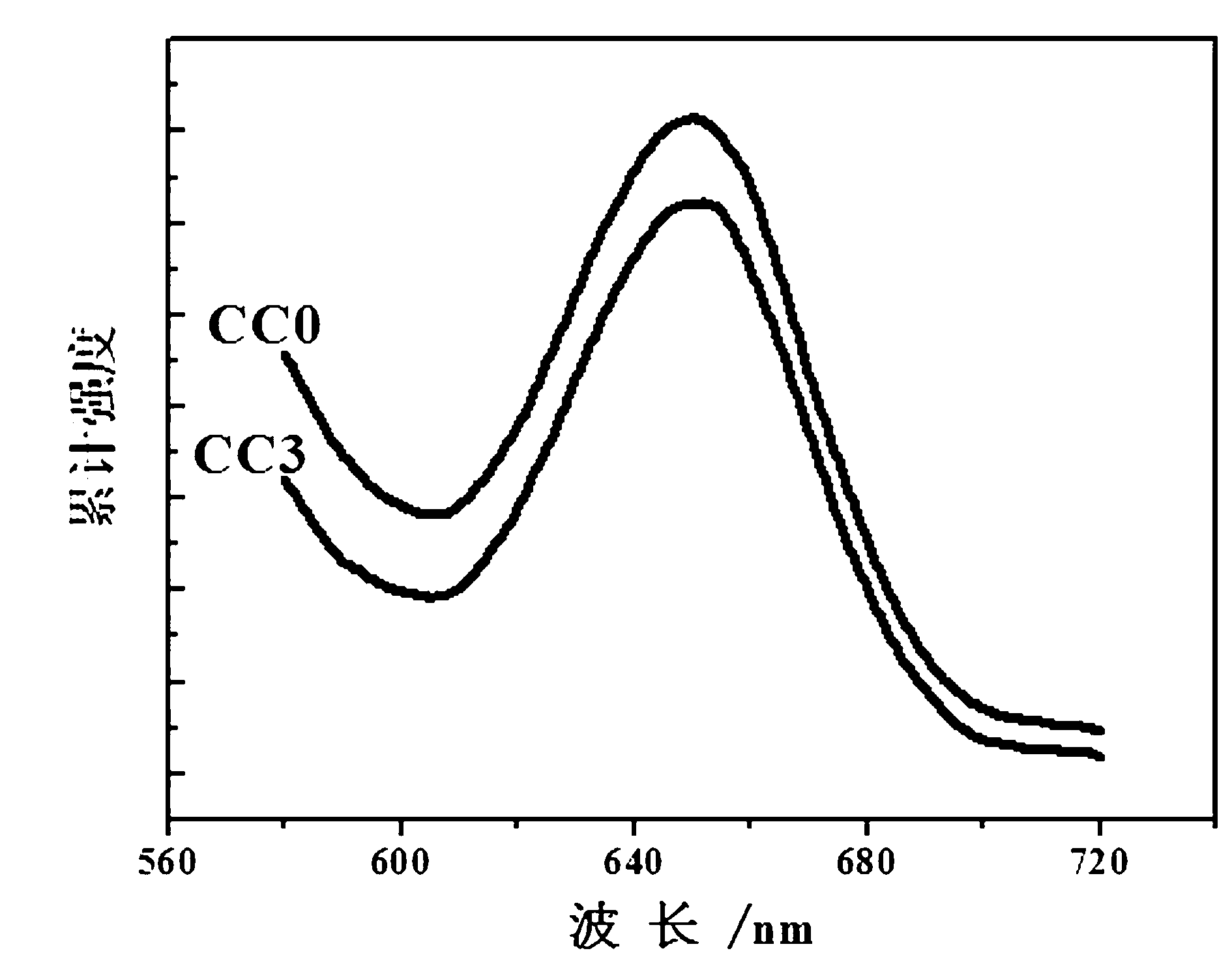

Embodiment 3

[0053] 1. Preparation of photocatalyst Cd / CdS

[0054] (1) 4.617 g of 3CdSO 4 ·8H 2 O was dissolved in 40 mL of distilled water to form a 0.15 M solution;

[0055] (2) 10.424 gNa 2 S 2 o 3 ·5H 2 O was dissolved in 40 mL of distilled water to make a concentration of 1.05 M Na 2 S 2 o 3 ·5H 2 O solution;

[0056] (3) 3CdSO 4 ·8H 2 O solution and Na 2 S 2 o 3 ·5H 2 The O solution was mixed, stirred for 20 min, and then ultrasonically treated for 15 min at an ultrasonic power of 100 Hz;

[0057] (4) The mixed solution was reacted under a 350W xenon lamp for 25 hours, and then heated in a 500W microwave oven for 20 minutes;

[0058] (5) The reaction solution was centrifuged at 8000 rpm to obtain a precipitate, washed 10 times with double distilled water, then washed 2 times with ethanol, dried at 80°C for 12 h, and ground to obtain a catalyst sample containing co-catalyst Cd, record for CC3. Wherein the mass percentage of Cd is 16%.

[0059] 2. Performance test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com