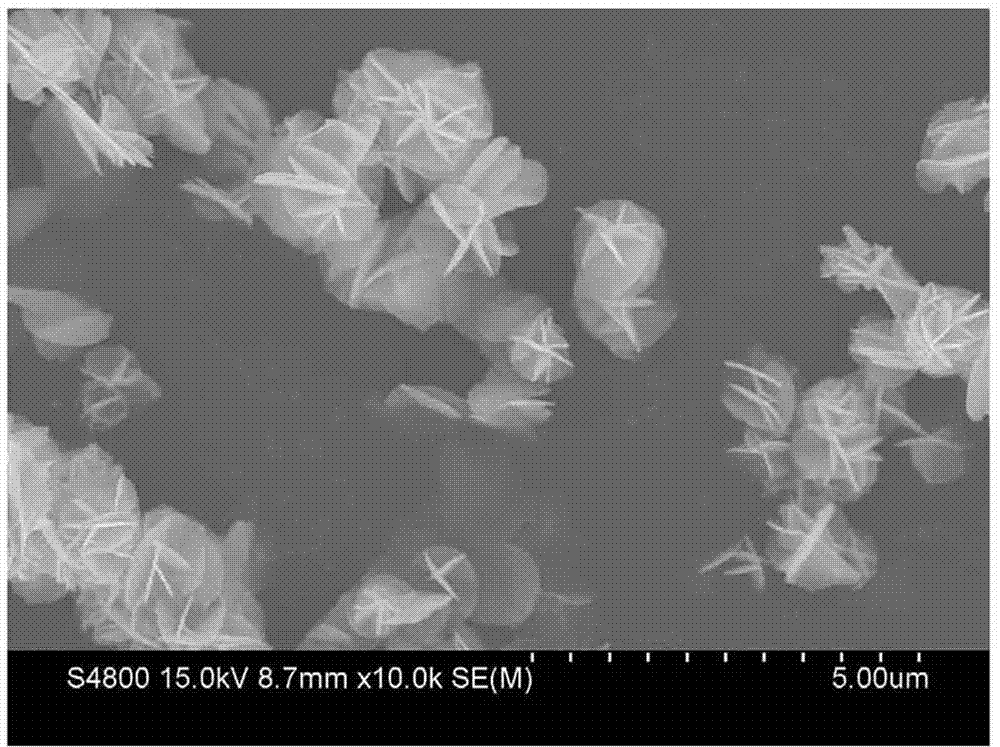

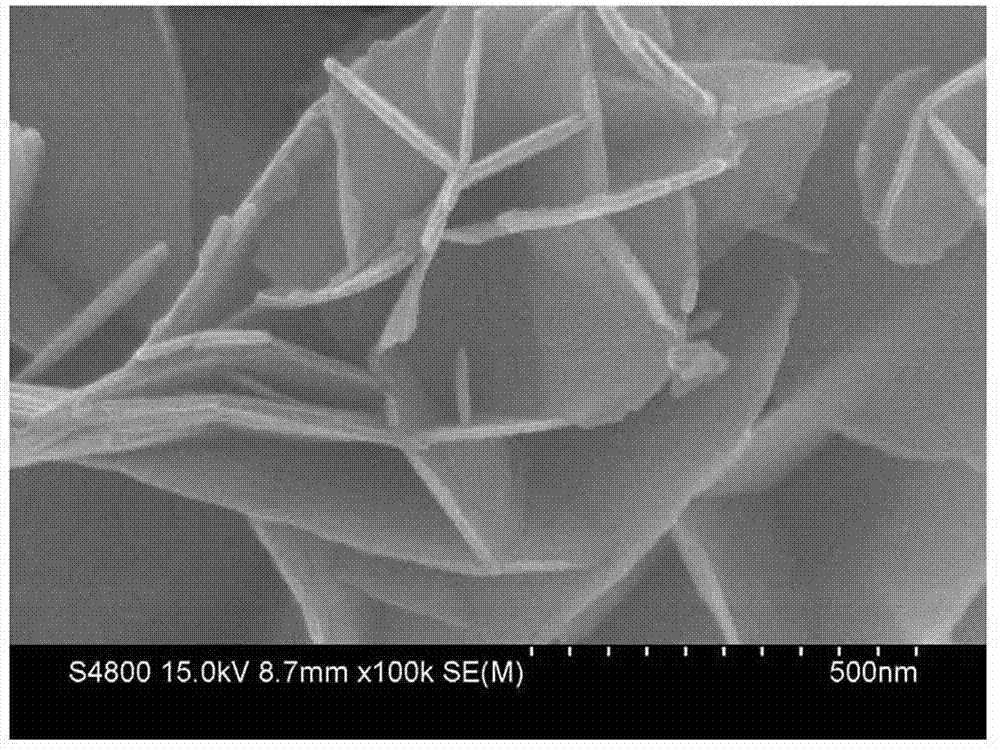

Method for preparing Bi2S3/BiOCl heterojunction photocatalyst

A photocatalyst and heterojunction technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of easy operation, high purity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Add 50g of triethylenetetramine to 200mL of deionized water and stir to dissolve, weigh diethyl sulfate in a molar ratio of 1:1 and slowly add it dropwise to the aqueous solution of triethylenetetramine, and stir to neutralize it. . An ice bath was set in the reaction process to prevent the solution from volatilizing due to exothermic heat. After stirring for 6 hours, the water in the mixed solution was evaporated using a rotary evaporator to obtain a triethylenetetramine diethyl sulfate ionic liquid.

[0031] (2) Preparation of chlorine-containing imidazole ionic liquid: 40.1799 g of imidazole was weighed into a three-necked flask, and then 48.12 g of hydrochloric acid (37%) was added dropwise to the imidazole solution under stirring, and stirred at 50°C for 3 hours. The imidazolium chloride ionic liquid was isolated by rotary evaporator.

[0032](3) Preparation of BiOCl: 2.4257g of bismuth nitrate was dissolved in 20ml of deionized water, 0.6g of imidazole chlor...

Embodiment 2

[0035] (1) Add 50g of triethylenetetramine to 200mL of deionized water and stir to dissolve, weigh diethyl sulfate in a molar ratio of 1:1 and slowly add it dropwise to the aqueous solution of triethylenetetramine, and stir to neutralize it. . An ice bath was set in the reaction process to prevent the solution from volatilizing due to exothermic heat. After stirring for 6 hours, the water in the mixed solution was evaporated using a rotary evaporator to obtain a triethylenetetramine diethyl sulfate ionic liquid.

[0036] (2) Preparation of chlorine-containing imidazole ionic liquid: weigh 40.1799 g of imidazole in a three-necked flask, add 50 ml of water to dissolve, then take 48.12 g of hydrochloric acid (37%) and add it dropwise to the imidazole solution under stirring, 50 Stir at ℃ for 3h. Impurities such as water were separated by rotary evaporator to obtain imidazolium chloride ionic liquid.

[0037] (3) Preparation of BiOCl: 2.4257g of bismuth nitrate was dissolved in ...

Embodiment 3

[0040] (1) Add 60 g of triethylene tetramine into 200 mL of deionized water and stir to dissolve, weigh diethyl sulfate in a molar ratio of 1:1 and slowly add it dropwise to the aqueous solution of triethylene tetramine, and stir to neutralize it. . An ice bath was set in the reaction process to prevent the solution from volatilizing due to exothermic heat. After stirring for 6 hours, the water in the mixed solution was evaporated using a rotary evaporator to obtain a triethylenetetramine diethyl sulfate ionic liquid.

[0041] (2) Preparation of chlorine-containing imidazole ionic liquid: weigh 40 g of imidazole in a three-necked flask, add 50 ml of water to dissolve, then take 48 g of hydrochloric acid (37%) and add it dropwise to the imidazole solution under stirring, at 50°C Stir for 3h. Impurities such as water were separated by rotary evaporator to obtain imidazolium chloride ionic liquid.

[0042] (3) Preparation of BiOCl: 2.4257g of bismuth nitrate was dissolved in 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com