Optical readout full-hollow focal plane array provided with thermal sink structures and manufacturing method thereof

A focal plane array and optical readout technology, applied in the field of semiconductors, can solve the problems that the pixel structure cannot work independently, cannot be transferred to the substrate in time, and cannot be effectively controlled by FPA, and achieves the elimination of thermal crosstalk, low cost, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and by taking specific implementations as examples. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

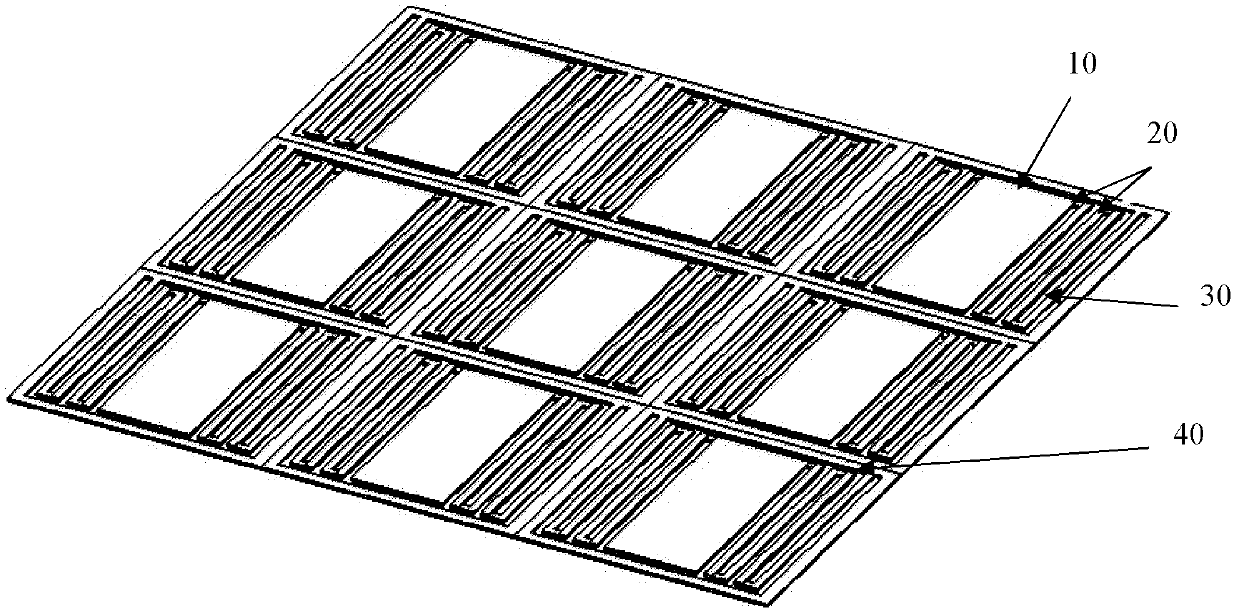

[0032] Such as figure 1 Shown is a three-dimensional schematic diagram of a single pixel of an opto-mechanical fully hollow focal plane array detector in the prior art, wherein each pixel includes a frame 40 and within the frame 40: a reflector 10, and two left and right The double-material deformed beam 20 is on the same plane as the two thermal isolation beams 30, the frame 40 and other components of the pixel.

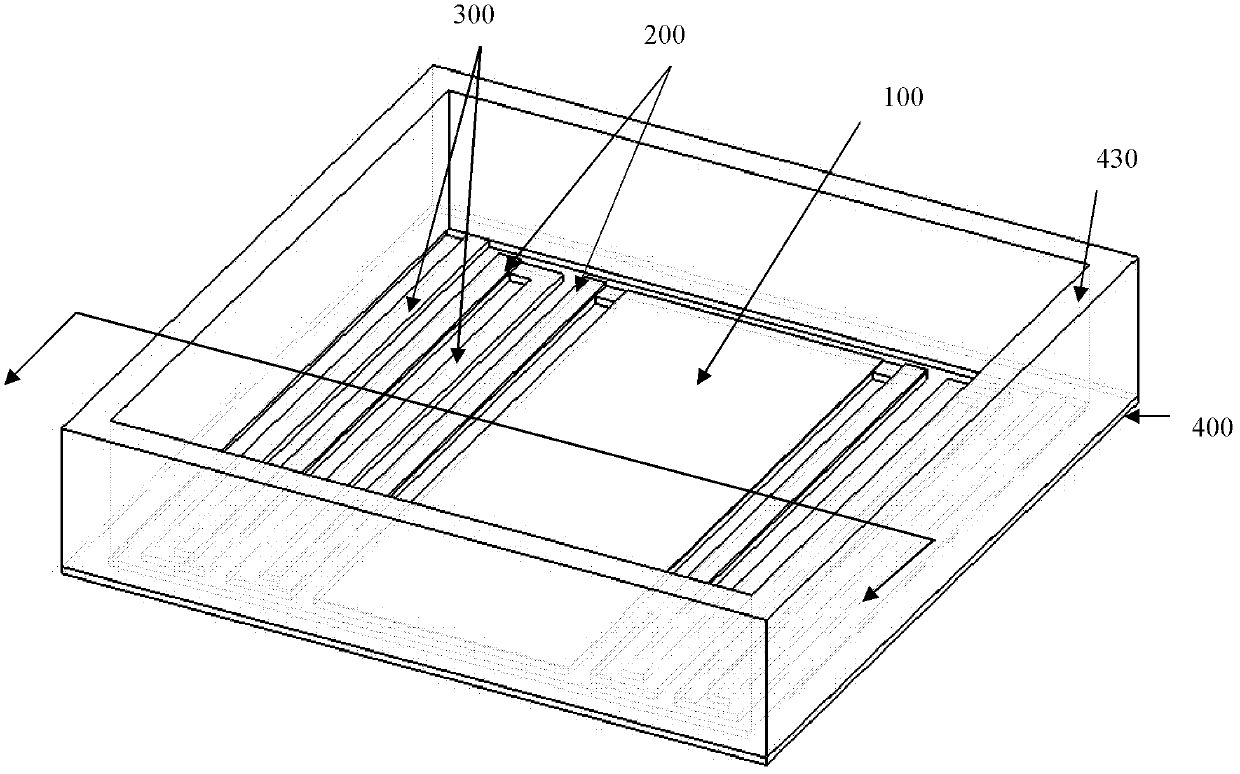

[0033] Such as figure 2 Shown is a three-dimensional schematic diagram of a single pixel unit of the optical readout full hollow focal plane array ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com