Synthetic method of porous ZnO three-dimensional superstructure assembled by nano-sheets

A synthesis method and superstructure technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of small size and complicated manufacturing methods, and achieve large size, low cost, and pore size distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

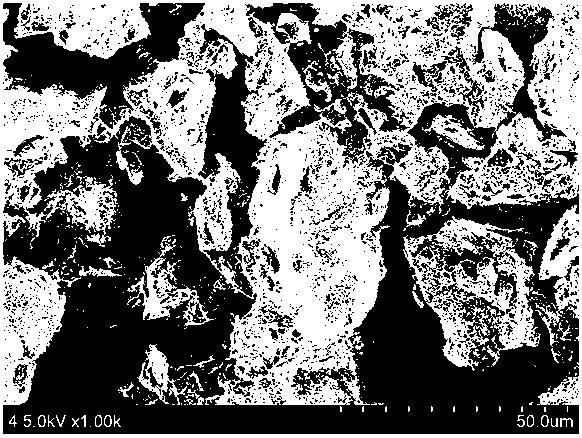

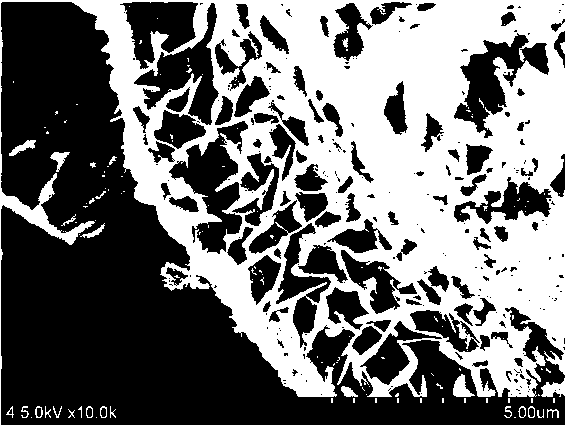

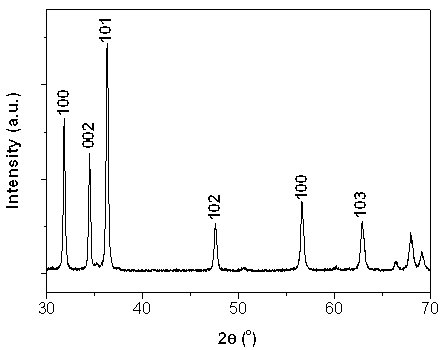

[0032] Pour 50mL of zinc ion (0.25 mol / L) precursor solution into a 250mL beaker, stir, and take another 40mL of ammonia water (0.5 mol / L) solution, put it in a separatory funnel, and pour the ammonia solution through the separatory funnel Within 30 minutes, add it dropwise to the zinc ion solution, continue to stir for 20 minutes, stand still, separate the precipitate by suction filtration, wash with distilled water and ethanol; dry in a constant temperature blast drying oven at 60~90°C; after complete drying, take out Grind finely to obtain a white powder. Weigh 0.4g of white powder sample, pour it into a 100ml beaker, add 20mL of distilled water to mix, and magnetically stir; then weigh 0.6g of anhydrous sugar and pour it into the beaker. After heating and stirring for a period of time. Take out the stirring bar, put the beaker in a drying oven at 60~90°C to dry; after complete drying, a white powder is obtained. The white powder was calcined in a high-temperature tube fu...

Embodiment 2

[0034]Pour 50mL of zinc ion (0.25 mol / L) precursor solution into a 250mL beaker, stir, and take another 50mL of ammonia water (0.5 mol / L) solution, put it in a separatory funnel, and pour the ammonia solution Within 40 minutes, add it dropwise to the zinc ion solution, continue to stir for 20 minutes, stand still, separate the precipitate by suction filtration, wash with distilled water and ethanol; dry in a constant temperature blast drying oven at 60~90°C; after complete drying, take out Grind finely to obtain a white powder. Weigh 0.4g of white powder sample, pour it into a 100ml beaker, add 20mL of distilled water to mix, and magnetically stir; then weigh 0.7g of anhydrous sugar and pour it into the beaker. After heating and stirring for a period of time. Take out the stirring bar, put the beaker in a drying oven at 60~90°C to dry; after complete drying, a white powder is obtained. The white powder was calcined in a high-temperature tube furnace at 400°C for 2 hours unde...

Embodiment 3

[0036] Pour 50mL of zinc ion (0.25 mol / L) precursor solution into a 250mL beaker, stir, and take another 60mL of ammonia water (0.5 mol / L) solution, put it in a separatory funnel, and pour the ammonia solution Add it dropwise to the zinc ion solution within 50 minutes, continue to stir for 20 minutes, stand still, separate the precipitate by suction filtration, wash with distilled water and ethanol; dry in a constant temperature blast drying oven at 60~90°C; after complete drying, take out Grind finely to obtain a white powder. Weigh 0.4g of white powder sample, pour it into a 100ml beaker, add 20mL of distilled water to mix, and magnetically stir; then weigh 0.8g of anhydrous sugar and pour it into the beaker. After heating and stirring for a period of time. Take out the stirring bar, put the beaker in a drying oven at 60~90°C to dry; after complete drying, a white powder is obtained. The white powder was calcined in a high-temperature tube furnace at 500°C for 3 hours unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com