Economical hybrid power biological membrane process

A hybrid power and biofilm technology, applied in aerobic and anaerobic process treatment, general water supply conservation, energy and wastewater treatment, etc., can solve the problems of limited treatment capacity and large site, reduce operating costs, improve treatment effect, Great return on investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

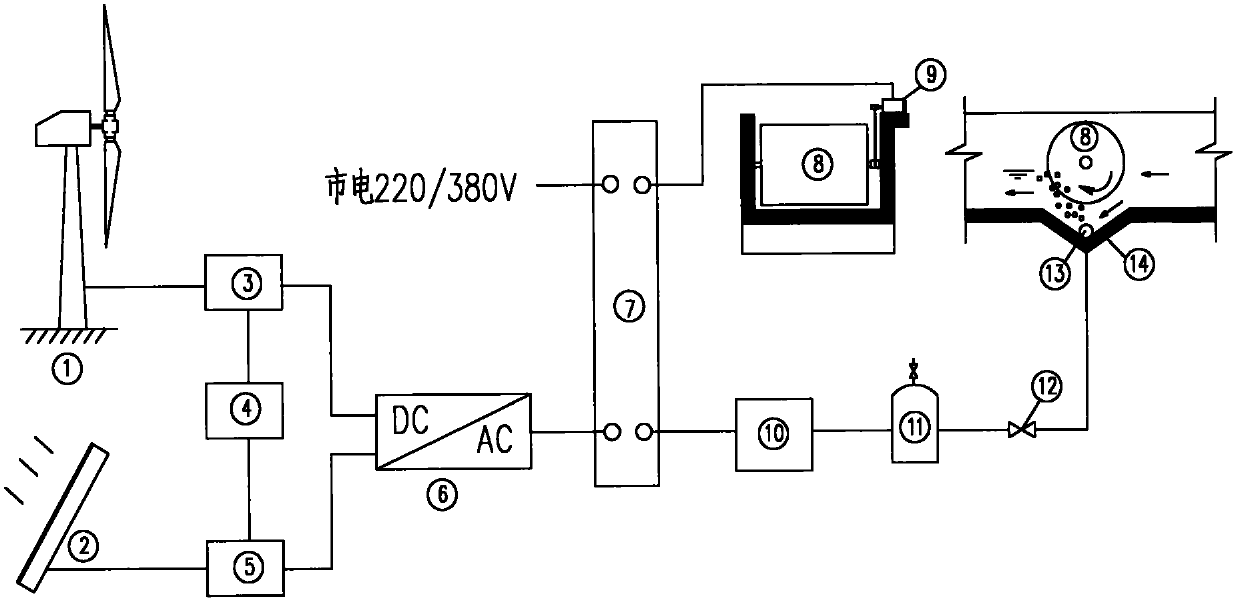

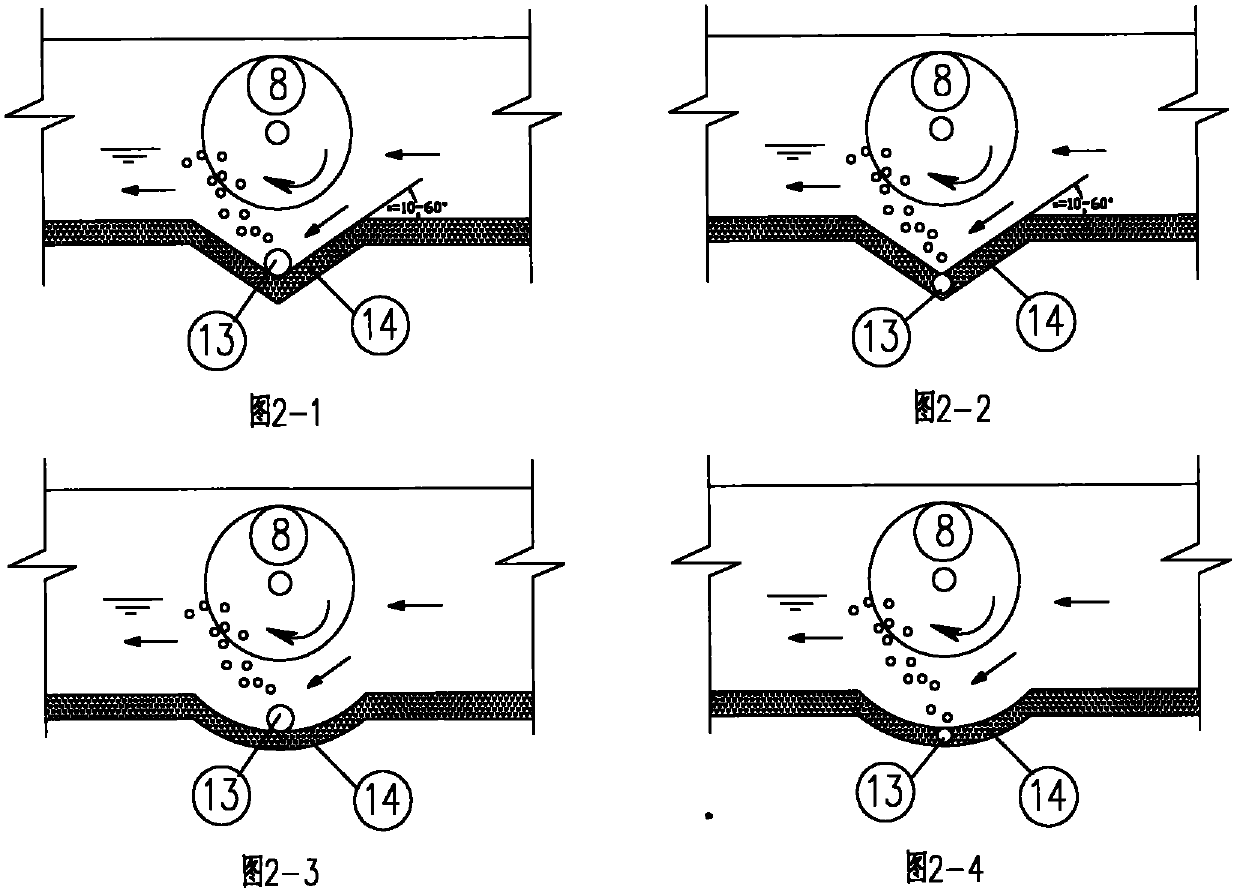

[0011] The invention relates to an economical hybrid biofilm process, as attached figure 1 As shown, it includes: wind power generator 1, solar photovoltaic module 2, wind energy controller 3, battery pack 4, solar controller 5, inverter 6, power switch box 7, biofilm group 8, membrane group matching motor 9, Air compressor / air pump 10, air storage tank 11, control valve 12, aeration pipe 13, drainage aeration tank 14, etc.

[0012] An economical hybrid biofilm process of the present invention, as attached figure 1 , under the condition of light, the solar photovoltaic modules 2 are connected in series and parallel to form a square array of solar photovoltaic cells and generate a certain voltage. The solar controller 5 is converted into 220V or 380V AC by the inverter 6 to supply power to the load, and the excess electricity charges the battery pack 4, and converts the electrical energy converted from light energy into chemical energy for storage. In the absence of light, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com