Method for producing fiberglass by using pulping and papermaking white mud

A glass fiber, pulping and papermaking technology, applied in the field of glass fiber production, can solve the problems of white mud waste environmental pollution, land occupation, etc., achieve obvious environmental and economic benefits, reduce costs, and reduce mining and consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

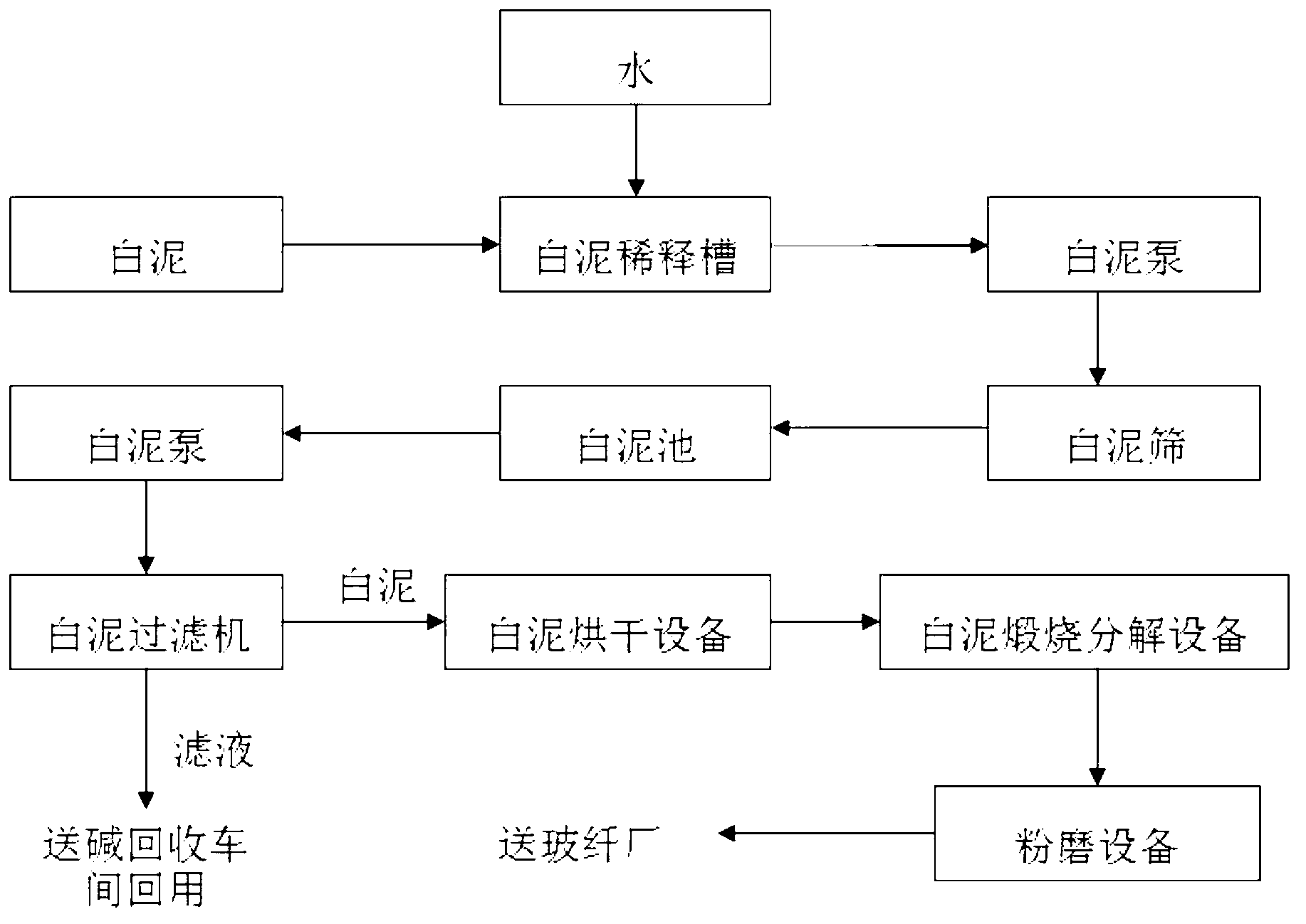

Method used

Image

Examples

Embodiment 2

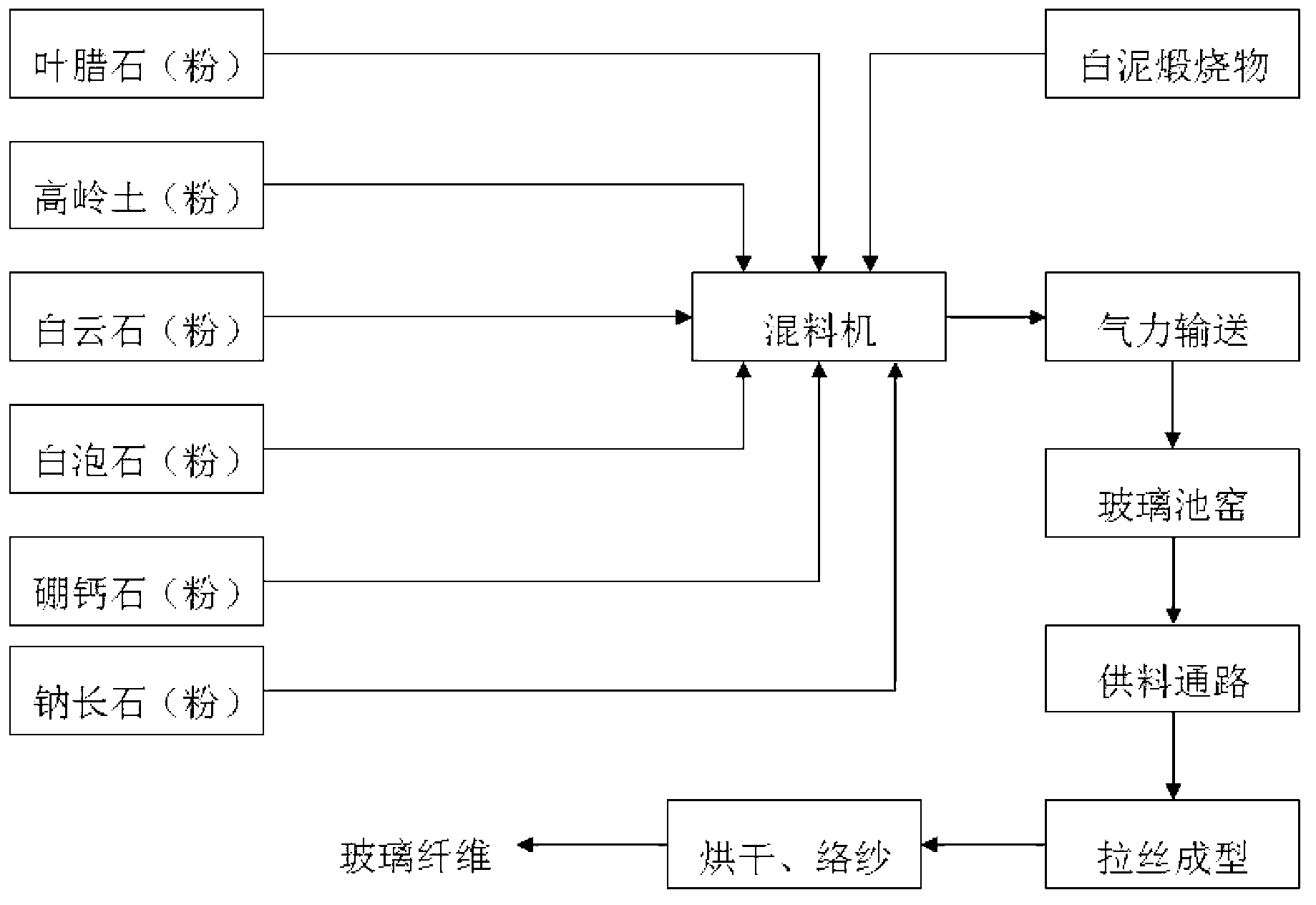

[0019] In this example, the calcined lime mud treated in Example 1 is used as raw material to prepare glass fiber. The specific operation steps are as follows: (1) Weigh the raw materials according to the following proportions: 50 parts of pyrophyllite, 10 parts of leucolite, dolomite 6 parts of limestone, 10 parts of calcined white clay, 25 parts of kaolin, 7 parts of boronite and 6 parts of albite. Among them, the particle size of albite, dolomite, and calcined white mud is ≤100 mesh, that of boronite is ≤200 mesh, and that of kaolin, pyrophyllite, and leucolite is ≤325 mesh. (2) Send all kinds of raw materials into the pneumatic mixing and stirring sender, and stir evenly, and the uniformity is greater than 92%; (3) Send the uniformly mixed materials into the glass tank furnace for melting to obtain high-temperature glass liquid; melting temperature It is controlled within the range of 1600°C; the melting time is 72h; (4) After clarification and homogenization, the obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com