Hydrophobic/hydrophilic crosslinked polydivinylbenzene/polyacryl polyethylene polyamine interpenetrating polymer network and preparation method thereof

A technology of polyacrylamide polyvinylpolyamine and polydivinylbenzene, which can be used in chemical instruments and methods, other chemical processes, etc., and can solve problems such as few research reports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

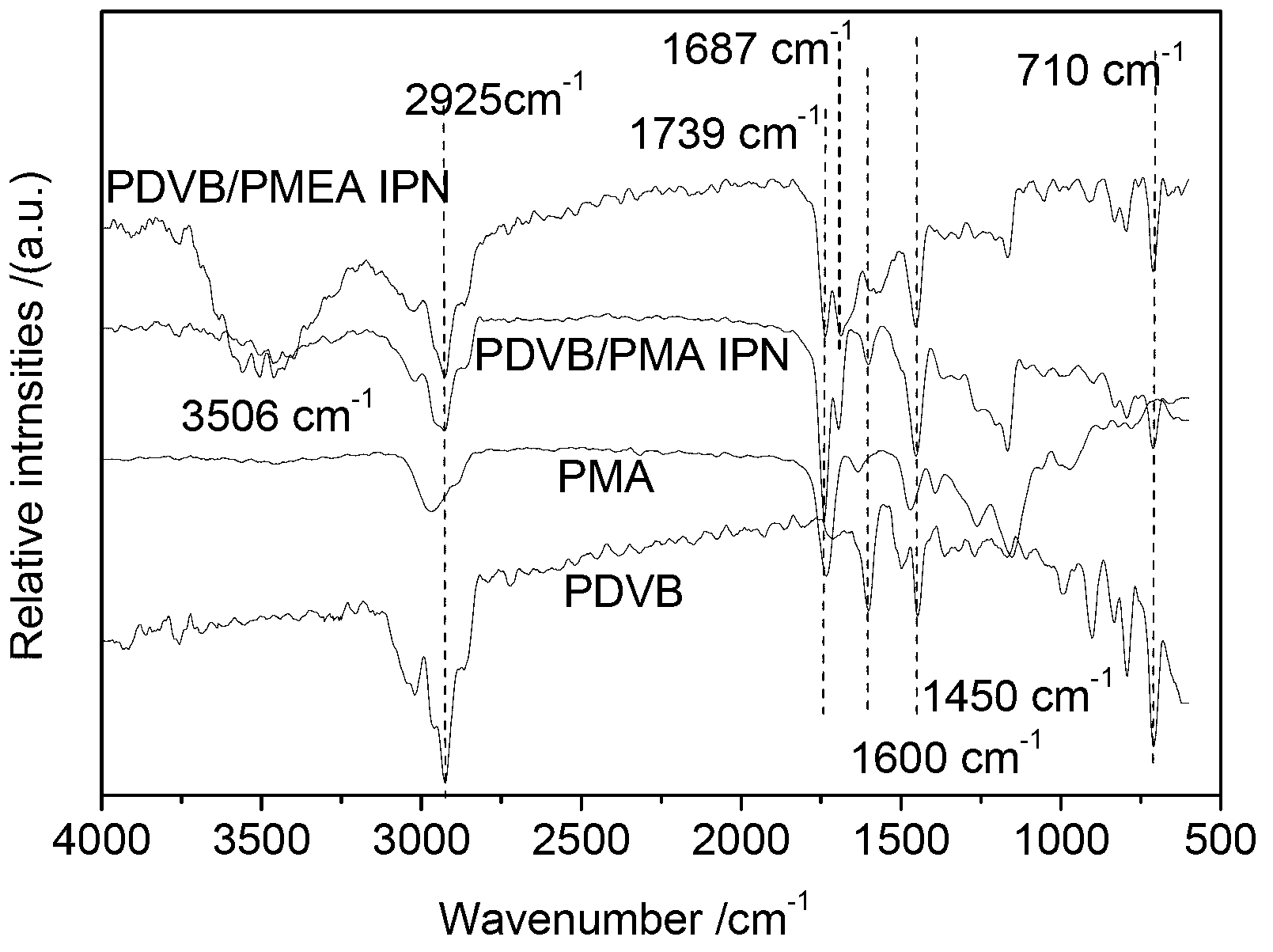

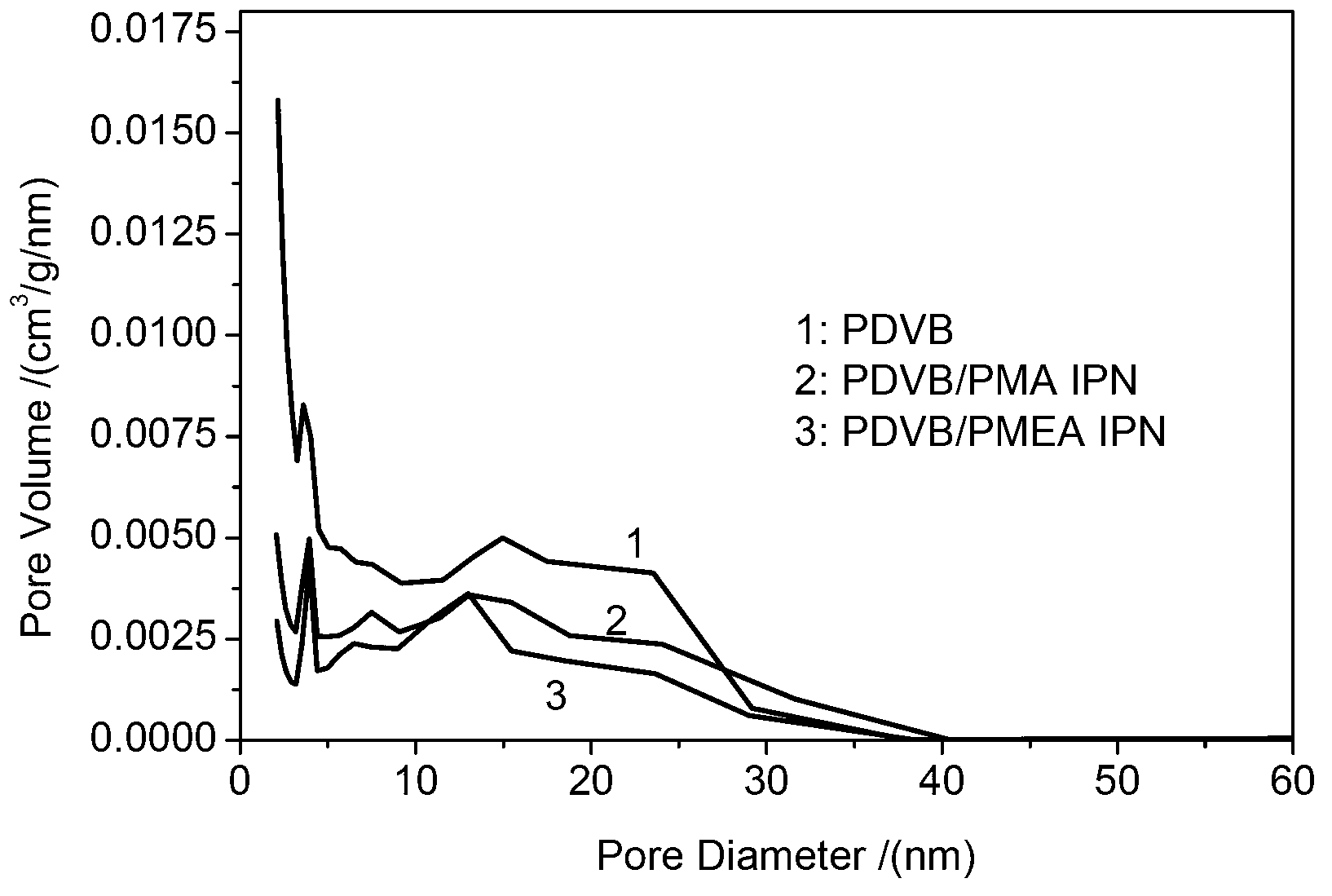

[0044] Preparation of cross-linked polydivinylbenzene (PDVB) macroporous microspheres: add 200mL of 1wt% PVA aqueous solution to a 500mL three-necked flask equipped with a reflux condenser, a thermometer and a mechanical stirrer, raise the temperature to 45°C, and add a certain amount of Mixed oil phase of DVB, toluene (150% of DVB by mass), n-heptane (50% by mass of DVB) and benzoyl peroxide (1wt% of DVB), adjust the stirring speed, control the size of oil droplets, Slowly raise the temperature to 78°C for 1 hour of polymerization, then raise the temperature to 85°C for 2 hours of polymerization, continue to heat up to 95°C and cook the balls for 6 hours; pour out the product, wash with hot water and cold water respectively, and extract with petroleum ether for 24 hours to remove the porogen, and dry to obtain PDVB resin; the measured Brunauer-Emmett-Teller (BET) specific surface area of PDVB is 616.1m 2 / g, the pore volume is 1.205cm 3 / g, the water absorption is 13.0wt%....

Embodiment 2

[0048] Preparation of PDVB: Add 200mL of 1wt%PVA aqueous solution into a 500mL three-necked flask equipped with a reflux condenser, a thermometer and a mechanical stirrer, raise the temperature to 50°C, and add a certain amount of DVB and toluene (the mass is 120% of DVB) under stirring. ), n-heptane (40% of DVB by mass) and benzoyl peroxide (0.5% of DVB by mass), adjust the stirring speed, and control the size of oil droplets; slowly heat up to 75°C for 1h, Then heat up to 85°C to polymerize for 2 hours, continue to heat up to 95°C to cook the balls for 6 hours; pour out the product, wash with hot water and cold water respectively, and extract with petroleum ether for 24 hours to remove the porogen, and dry to obtain PDVB resin; measure the BET of the resin The specific surface area is 566.8m 2 / g, the pore volume is 1.009cm 3 / g, the water absorption is 14.7wt%.

[0049] Preparation of PDVB / PMA IPN: Weigh a certain amount of PDVB resin, mix MA (mass is 180% of PDVB), TAIC ...

Embodiment 3

[0052] Preparation of PDVB: Add 200mL of 1wt%PVA aqueous solution into a 500mL three-necked bottle, heat up to 50°C, add a certain amount of DVB, toluene (150% of DVB by mass), n-heptane (70% of DVB by mass) under stirring ) and benzoyl peroxide (1.0% of DVB) mixed oil phase, adjust the stirring speed, control the size of oil droplets; slowly raise the temperature to 78°C for 1h polymerization, then raise the temperature to 85°C for 2h polymerization, continue to heat up to 95°C Boil the balls at ℃ for 6 hours; pour out the product, wash with hot water and cold water respectively, and extract with petroleum ether for 24 hours to remove the porogen, and dry to obtain the macroporous PDVB resin; the measured BET specific surface area of the resin is 708.9m 2 / g, the pore volume is 1.439cm 3 / g, the water absorption is 14.8wt%.

[0053] Preparation of PDVB / PMA IPN: Weigh a certain amount of PDVB resin, mix MA (mass is 80% of PDVB), TAIC (mass is 20% of PDVB), butyl acetate (ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com