Method for preparing material for adsorbing heavy metal ions and rare earth ions

A technology for adsorbing heavy metals and rare earth ions, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., and can solve problems such as the influence of the overall efficiency of monomer graft polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

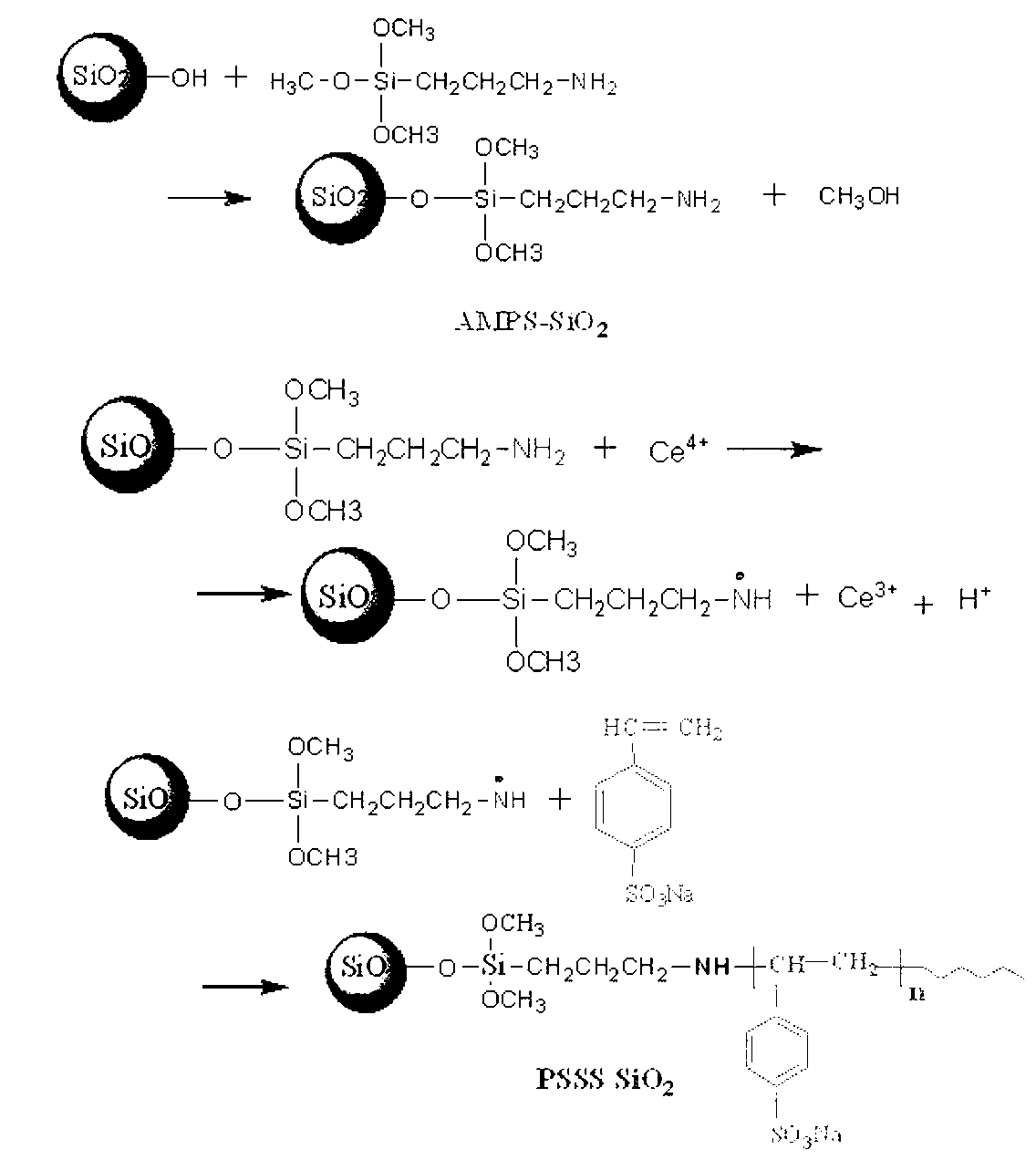

[0027] A method for preparing a material for adsorbing heavy metal ions and rare earth ions, comprising the following steps:

[0028] (1) Chemical modification of the surface of silica gel: add 10g of activated silica gel to 100ml of water solvent, and add 10ml of γ-aminopropyltrimethoxysilane AMPS, react at 50°C for 20h, and the product after suction filtration is repeated with ethanol Washed and dried in vacuum to prepare surface-modified silica particles AMPS-SiO 2 ;

[0029] (2) Graft polymerization initiated on the surface of monomeric sodium styrene sulfonate SSS: Add 1.2 g of silica gel particles to a four-necked flask equipped with an electric stirrer, reflux condenser, constant pressure dropping funnel, and nitrogen inlet tube AMPS-SiO 2 , then add 80 mL of distilled water and 16.54 g of monomeric sodium styrene sulfonate SSS, add 20 mL of an aqueous solution in which 0.42 g of ceric ammonium sulfate and 0.3 mL of concentrated sulfuric acid are dissolved in a consta...

Embodiment 2

[0033] A method for preparing a material for adsorbing heavy metal ions and rare earth ions, comprising the following steps:

[0034] (1) Chemical surface modification of silica gel: add 15g of activated silica gel to 150ml of water solvent, and add 15ml of γ-aminopropyltrimethoxysilane AMPS, react at 50°C for 24h, and the product after suction filtration is repeated with ethanol Washed and dried in vacuum to prepare surface-modified silica particles AMPS-SiO 2 ;

[0035] (2) Graft polymerization initiated on the surface of monomeric sodium styrene sulfonate SSS: add 1.4 g of silica gel particles to a four-necked flask equipped with an electric stirrer, reflux condenser, constant pressure dropping funnel, and nitrogen gas inlet AMPS-SiO 2 , then add 80 mL of distilled water and 17.67 g of monomeric sodium styrene sulfonate SSS, add 20 mL of an aqueous solution in which 0.44 g of ceric ammonium sulfate and 0.3 mL of concentrated sulfuric acid are dissolved in a constant press...

Embodiment 3

[0038] A method for preparing a material for adsorbing heavy metal ions and rare earth ions, comprising the following steps:

[0039] (1) Chemical modification of the surface of silica gel: add 12g of activated silica gel to 130ml of water solvent, and add 13ml of γ-aminopropyltrimethoxysilane AMPS, react at 50°C for 22h, and the product after suction filtration is repeated with ethanol Washed and dried in vacuum to prepare surface-modified silica particles AMPS-SiO 2 ;

[0040] (2) The surface of the monomer sodium styrene sulfonate SSS initiates graft polymerization: In a four-necked flask equipped with an electric stirrer, a reflux condenser, a constant pressure dropping funnel and a nitrogen inlet pipe, add 1.3g of silica gel particles AMPS-SiO 2 , then add 80 mL of distilled water and 17.00 g of monomeric sodium styrene sulfonate SSS, add 20 mL of an aqueous solution in which 0.43 g of ceric ammonium sulfate and 0.3 mL of concentrated sulfuric acid are dissolved in a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com