A kind of sapphire crystal growth method and equipment

A technology of sapphire crystal and growth method, applied in the field of crystal growth, can solve the problem of difficult observation of sapphire single crystal, and achieve the effects of simplified post-processing procedures, improved material utilization rate and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The invention discloses a sapphire crystal growth method, which is an improved method based on the crucible drop method crystal growth technology, and is a sapphire crystal growth method for forming shaped sapphire crystals by designing the crucible shape.

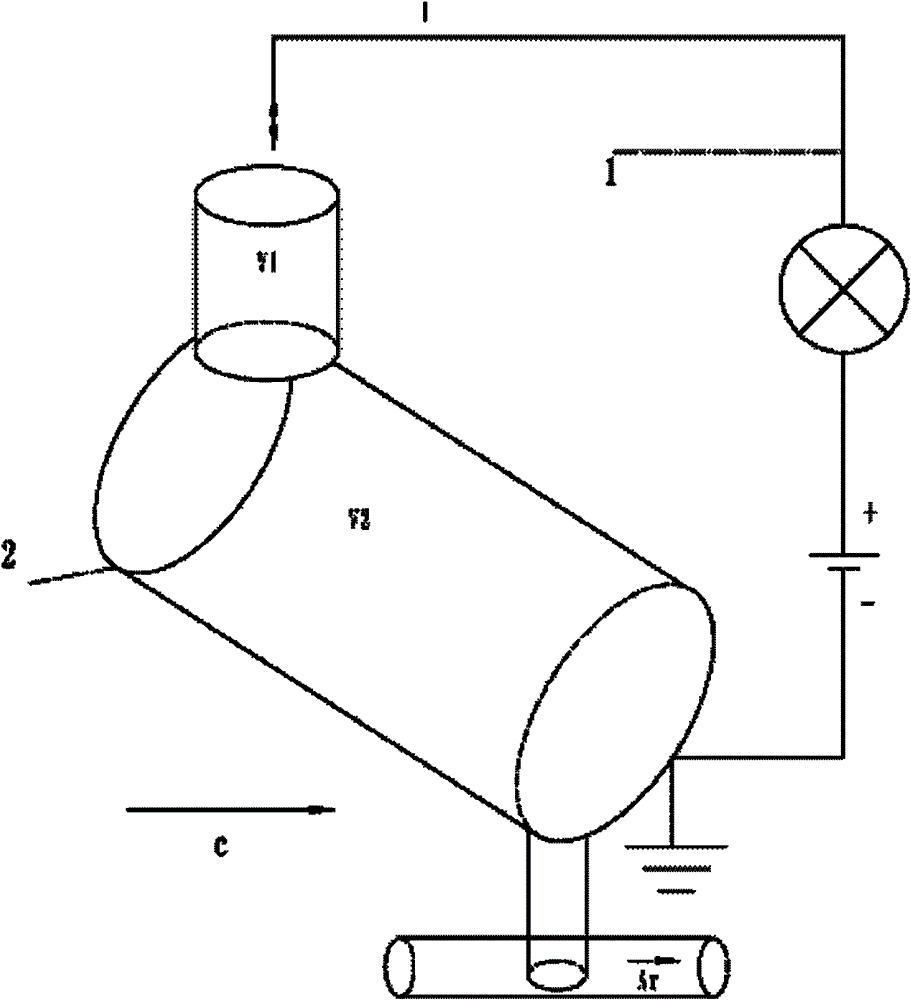

[0049] The present invention first discloses the improved sapphire crystal growth equipment used in the above growth method. The growth equipment includes a crucible 2, a liquid level sensor 1, a crystal growth furnace (not shown), and a heater (not shown).

[0050] see figure 1 , figure 1A schematic structural view of the crucible 2 and the liquid level sensor 1 is disclosed. The crucible 2 is arranged in the crystal growth furnace, and includes a crucible main body, a crucible upper mechanism arranged above the crucible main body, and an upper end opening of the crucible upper mechanism; the cross-sectional area s of the crucible upper mechanism is smaller than the cross-sectional area S of the crucible main bod...

Embodiment 2

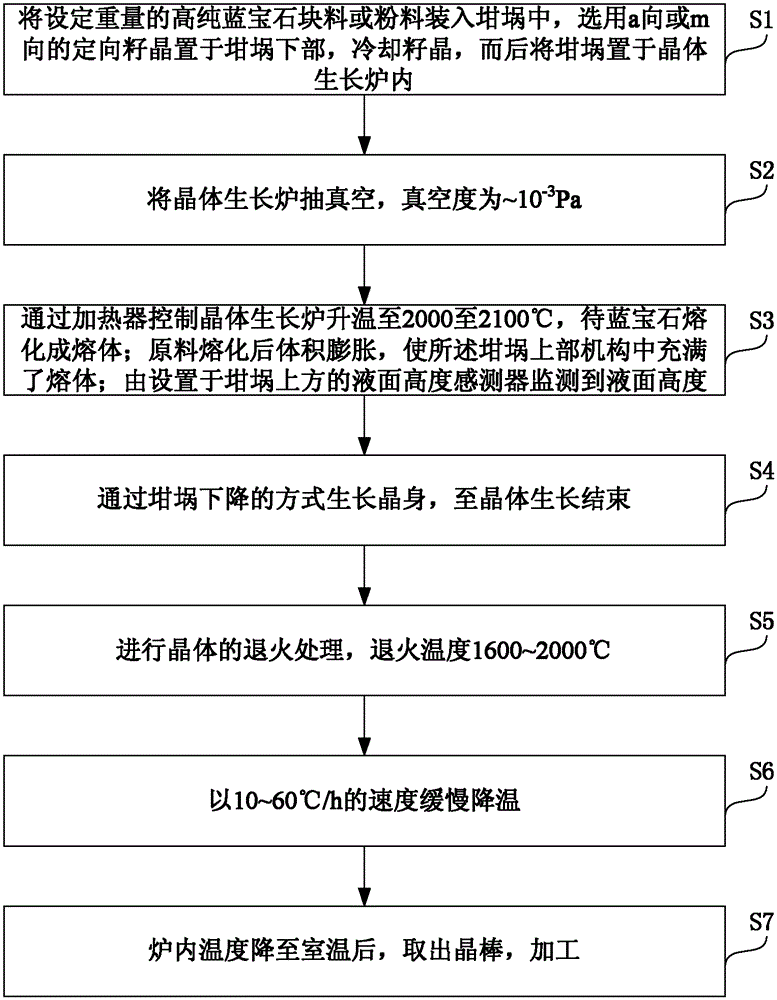

[0060] The difference between the present embodiment and the first embodiment is that, in the present embodiment, the growth method of the sapphire crystal comprises the following steps:

[0061] [Step S1] Put the high-purity sapphire block or powder of the set weight into the crucible, select the oriented seed crystal in the direction of a or m and place it in the lower part of the crucible, cool the seed crystal, and then place the crucible in the crystal growth furnace The crucible used comprises a crucible main body, a crucible upper mechanism arranged above the crucible main body, and an upper end opening of the crucible upper mechanism; the cross-sectional area s of the crucible upper mechanism is less than the crucible main body cross-sectional area (referring to the section perpendicular to the axis of the crucible main body) S 1 / 100 of;

[0062] [Step S2] Vacuum the crystal growth furnace to a degree of vacuum of ~10 -3 Pa;

[0063] [Step S3] Use the heater to contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com