Wind driven generator coupler slipping torque calibration test bed and calibration method

A technology for wind turbines and couplings, which is used in machine gear/transmission mechanism testing, instruments, torque measurement, etc., can solve problems such as large slip torque calibration error, lag in test judgment, and complex mechanism, and achieve good application. Value, easy adjustment, good human-computer interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

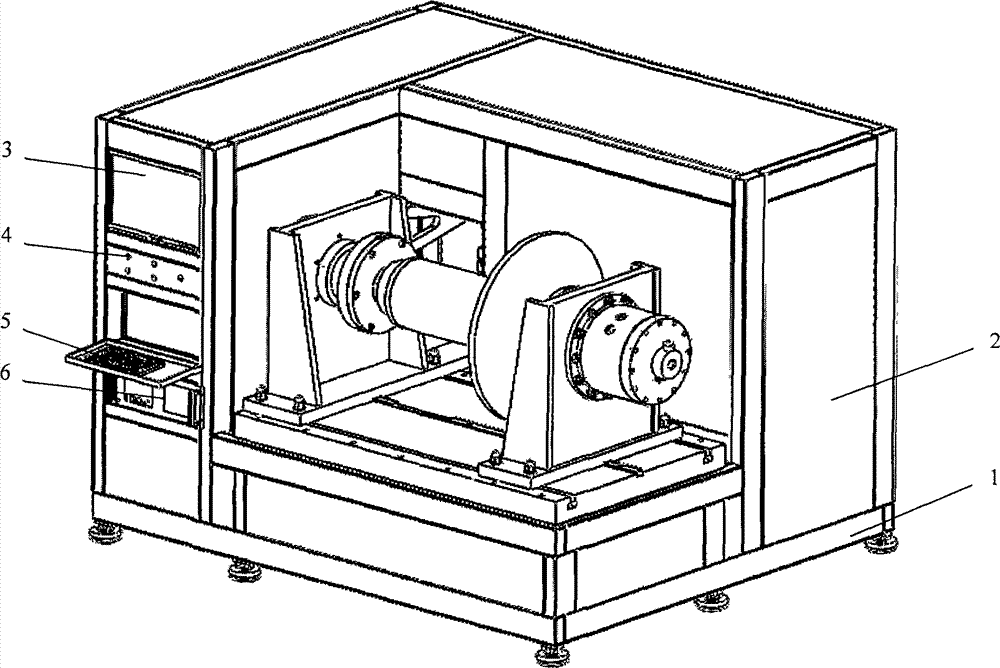

[0022] The wind turbine coupling slip torque calibration test bench of the present invention is mainly composed of a bench, a base plate, a torque loading mechanism, a torque output detection mechanism, a hydraulic system, and a computer control system; the base plate, the torque loading mechanism, the torque output detection mechanism, the hydraulic The system and computer control system are installed and fixed on the bench.

[0023] see figure 1 , The bench adopts a steel welded frame 1, and a steel plate door 2 is installed on the surface. For the rust prevention and beauty of the test bench, the surface of the test bench is painted.

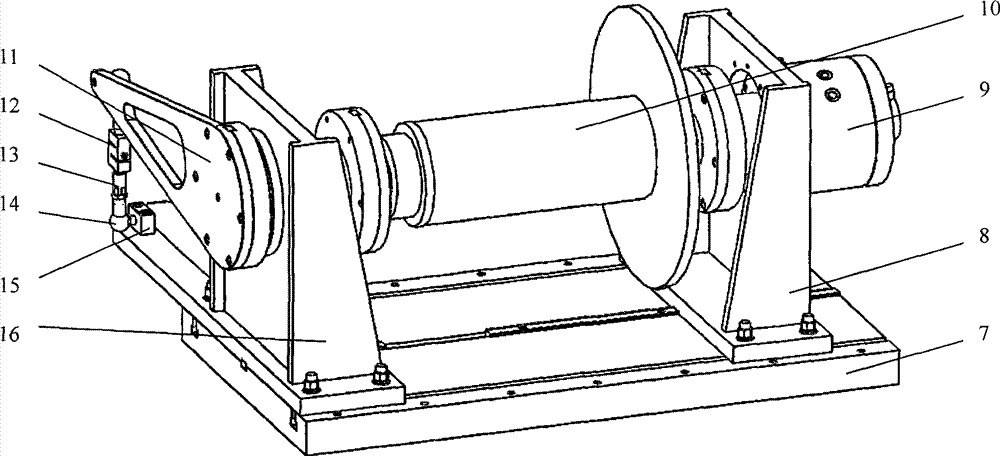

[0024] see figure 2 , the bottom plate 7 is a thick steel plate, which is fixed on the platform; there is a flat keyway running through the middle of the upper surface of the bottom plate, the flat key is installed in the flat keyway and fixed with bolts, and there is a longitudinally running T-slot on both sides of the flat keyway , the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com