Electro-hydraulic loading device based on hydraulic tractor steer-by-wire system

A steering system and loading device technology, applied in the direction of vehicle steering/bump performance, etc., can solve the problems of inability to continue, poor loading force and real-time performance, and achieve the effects of precise control, loading force, and simplification of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

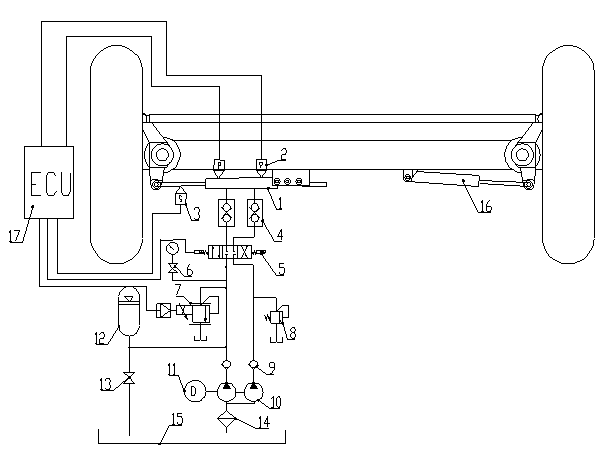

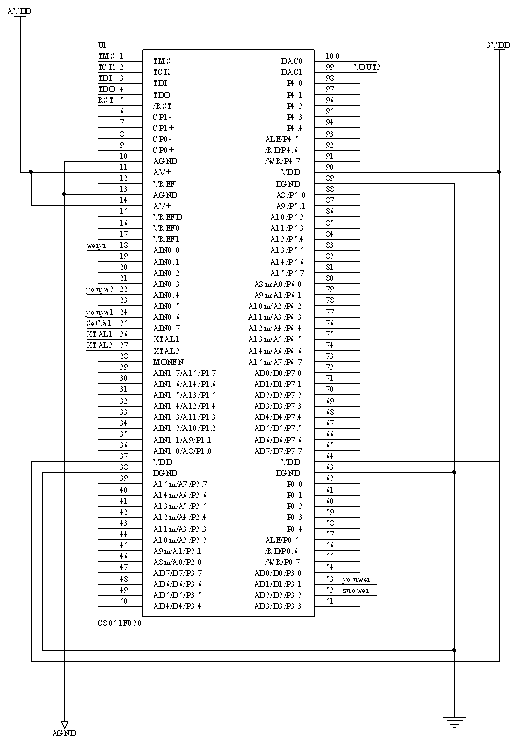

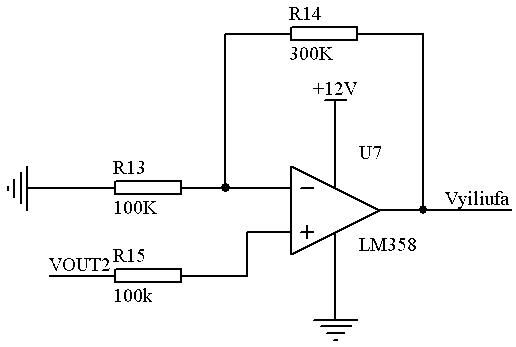

[0032] Such as Figure 1-2Shown: an electro-hydraulic loading device based on a tractor-by-wire hydraulic steering system, including a loading hydraulic cylinder 1 and a steering hydraulic cylinder 16, which are symmetrically arranged on both sides of the trapezoid of the steering system and pass through the The respective piston rods are connected to the steering knuckle of the steering system, and the piston rod of the loading hydraulic cylinder 1 is connected to the steering knuckle of the tractor steering system in order to apply the loading force to the steering knuckle to simulate the ground side of the tires during the steering of the tractor. towards resistance. The loading hydraulic cylinder 1 is connected to the electromagnetic reversing valve 5 through the hydraulic quick connector plug 4, and the oil inlet of the electromagnetic reversing v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com