Austenitic metal low temperature supersaturated gas carburizing surface strengthening test device

A gas carburizing and surface strengthening technology, applied in the direction of measuring devices, testing material hardness, instruments, etc., can solve the problems of harmful phases and compounds, uneven temperature, low carbon content, etc., and achieve disassembly and replacement of samples Convenience, uniform test temperature and simple operation

Active Publication Date: 2016-08-31

NANJING TECH UNIV

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, austenitic metals also have obvious disadvantages: extremely low carbon content, resulting in low surface strength and hardness, poor wear resistance and fatigue resistance, which restricts the application of austenitic metals in some heavy loads and Applications in equipment and components requiring high wear resistance

However, the low-temperature ion surface strengthening technology can only process parts with simple surface shapes, and cannot handle workpieces with complex shapes. Moreover, low-temperature ion surface strengthening treatment uses ion sputtering to heat the surface of austenitic metals, and the temperature at each point on the surface is not uniform. After treatment, the hardened layer will be uneven, and harmful phases and compounds may be formed locally, which will affect the performance of stainless steel. Therefore, the research on the surface strengthening technology of austenitic metals with low-temperature supersaturated gas has more practical significance, and a set of safe, reliable, high-precision The test device is the premise and key of related technology research

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

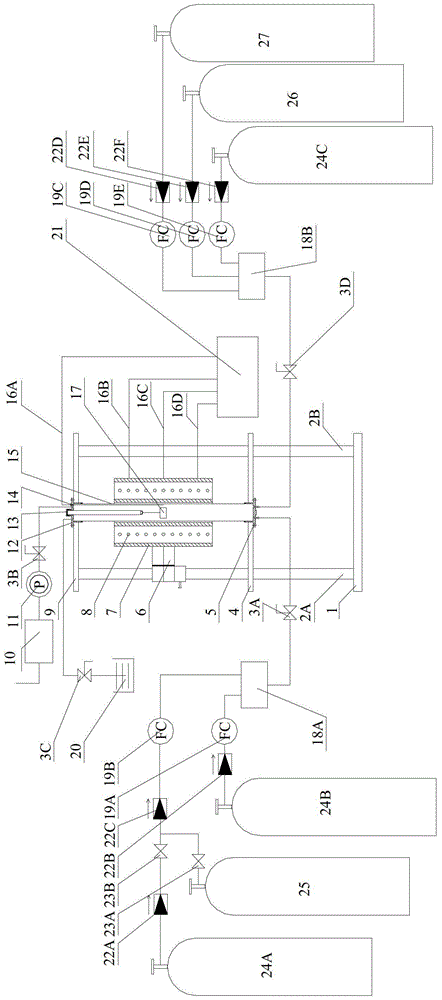

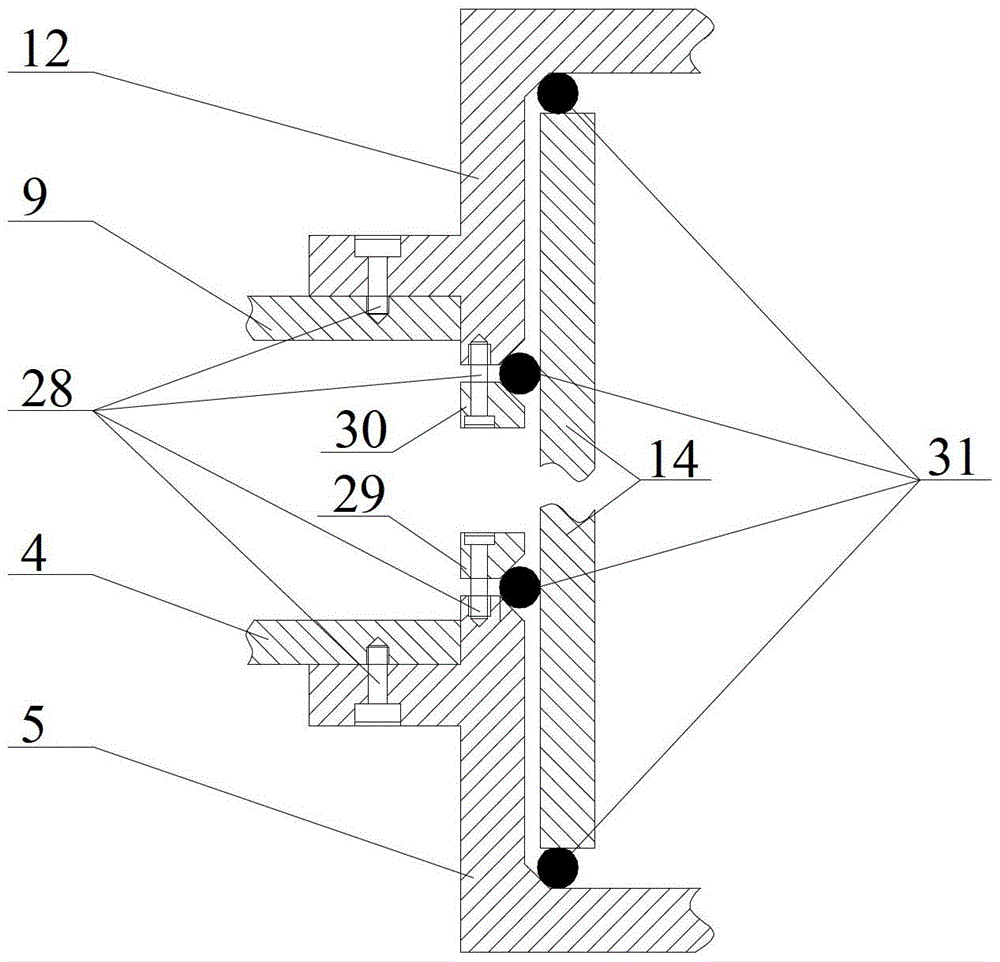

[0030] like figure 1 As shown, a set of test equipment for low-temperature supersaturated gas carburizing surface strengthening technology for austenitic metals consists of a support platform, temperature measurement and control system, sealing system and multi-atmosphere mixing system.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a test device, and especially relates to an austenite metal low-temperature supersaturated gas carburizing surface strengthening test device. A method comprises austenite metal surface activation pretreatment before carburizing and low-temperature gas carburizing treatment. The device is composed of a supporting platform, a temperature determination and control system, a sealing system, a multi-atmosphere mixing system, and a vacuum system. The invention aims at an austenite metal multi-atmosphere low-temperature supersaturated gas carburizing surface strengthening technology, and provides the test device with the advantages of uniform temperature field, high precision, simple operation, low cost, and capability of realizing continuous and uniform carburization.

Description

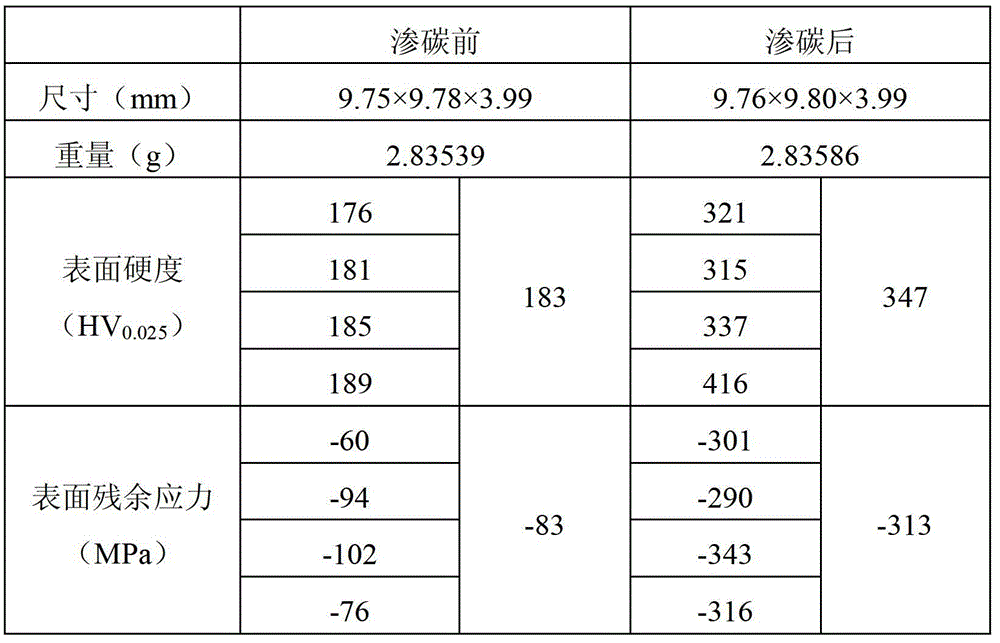

technical field [0001] The invention relates to a test device, in particular to a surface strengthening test device for low-temperature supersaturated gas carburization of austenitic metals, which can improve the surface strength, hardness and resistance of austenitic metals without reducing the corrosion resistance of austenitic metals. properties such as wear and tear. Background technique [0002] Austenitic metals are widely used in machinery, chemical, pharmaceutical and other industries due to their excellent mechanical properties, machinability and corrosion resistance. However, austenitic metals also have obvious disadvantages: extremely low carbon content, resulting in low surface strength and hardness, poor wear resistance and fatigue resistance, which restricts the application of austenitic metals in some heavy loads and Applications in equipment and components that require high wear resistance. [0003] So far, there are many technologies used to improve the su...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N3/40G01N5/02G01N21/84

Inventor 荣冬松巩建鸣姜勇耿鲁阳

Owner NANJING TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com